Method for preparing metal-organic framework film through vapor-phase-assisted deposition

An organic framework, gas-phase assisted technology, applied in the field of vapor-assisted deposition thin film preparation, can solve problems such as the inability to meet the requirements of high-quality MOF thin film preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047]The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0048] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

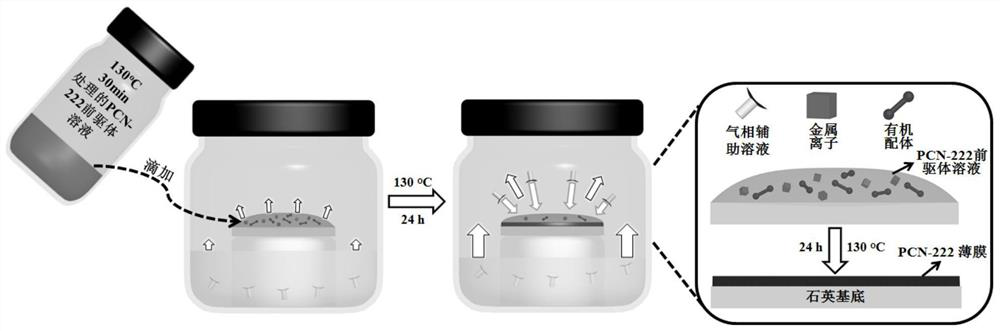

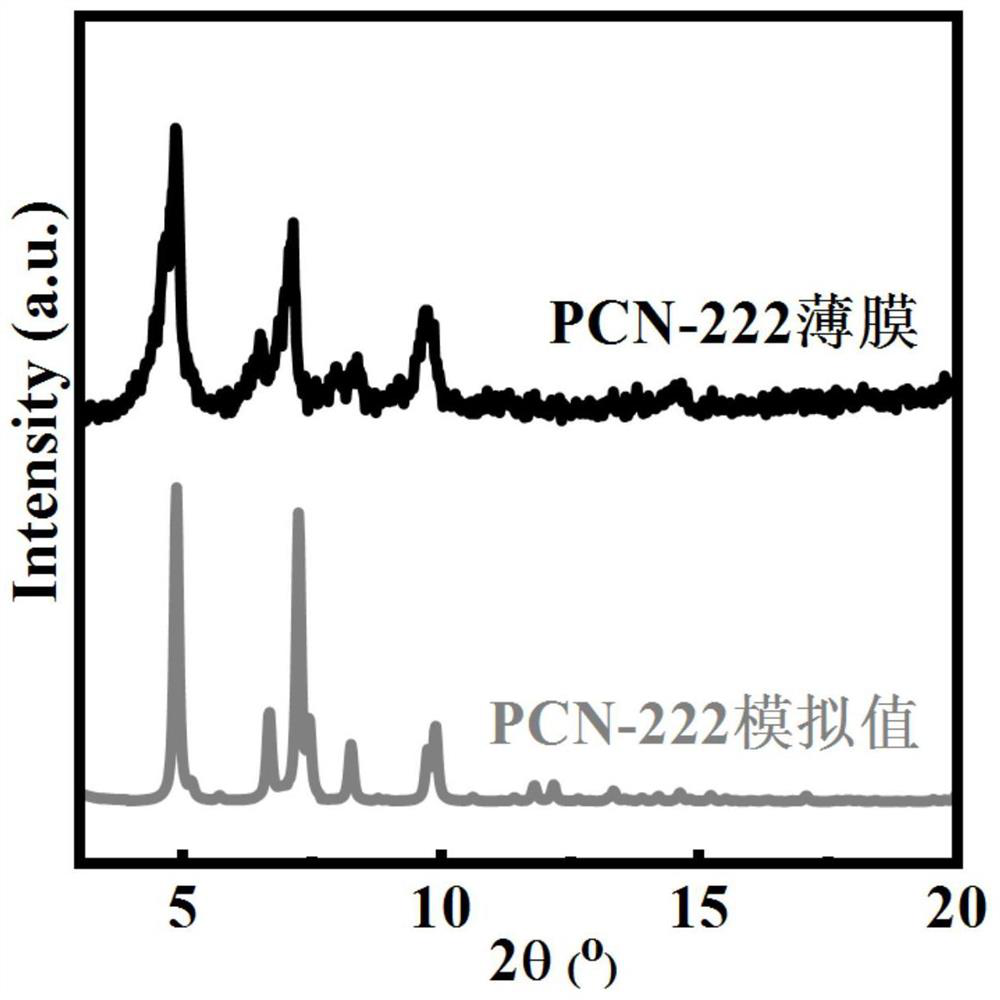

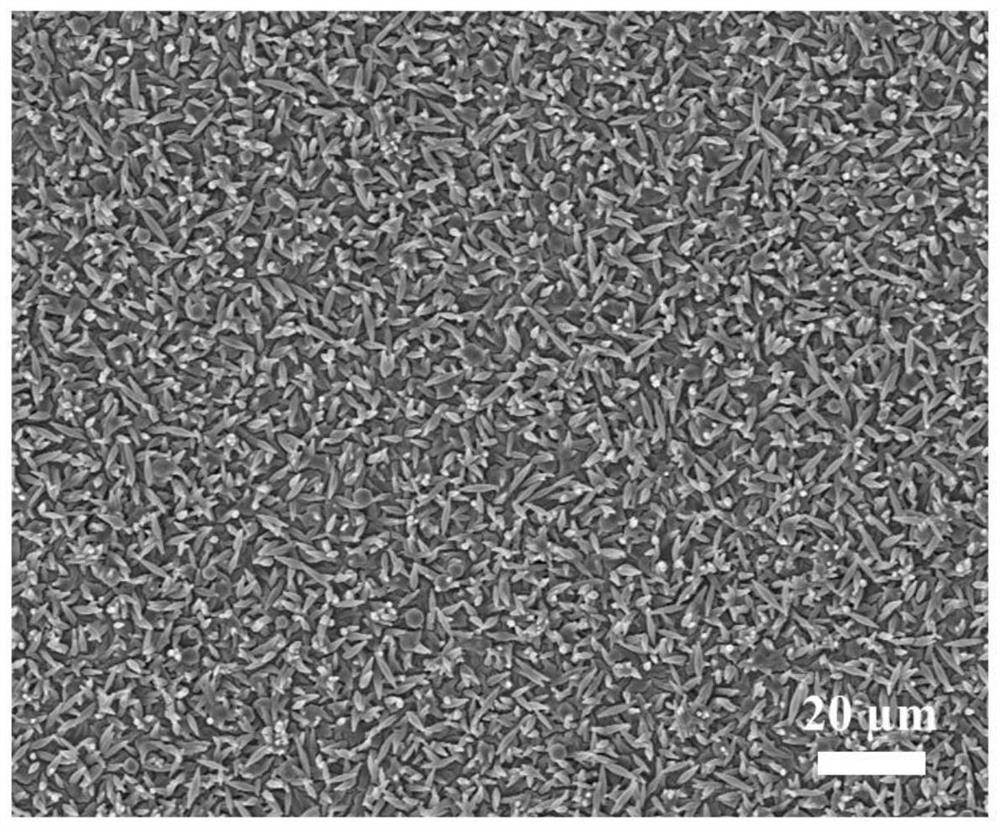

[0050] 1) Preparation of PCN-222 thin film precursor material by vapor-assisted deposition method

[0051] Weigh 15mg of zirconium tetrachloride and 0.54g of benzoic acid and dissolve it in 1mL of DMF, place it in 130°C for 1 hour after ultrasonication for 15 minutes, then take 6mg of TCPP and add it to 1mL DMF solution for 15 minutes, then add TCPP solution into tetrachloride Zirconium chloride / benzoic acid solution, ultrasonic for 5 minutes, and place the above solution at 130° C. for 30 minutes to obtain a PCN222 precursor solution for use. The gas phase auxiliary solution is DMF.

[0052] The quartz substrate (1cm×1cm) was firstly ultrasonicated with acetone, 2M hydrochloric acid, and distilled water for 5 minutes, blown dry with nitrogen, and then placed in a solution of 0.02M NaOH and hydrogen peroxide (30%) with a volume ratio of 3:1 at 80°C. After 30 minutes, a hydroxyl-modified quartz substrate was obtained.

[0053] Take an airtight high-temperature-resistant glass...

Embodiment 2

[0058] 1) Preparation of NU-1000 thin film precursor material by vapor-assisted deposition method

[0059] Weigh 15mg of zirconium tetrachloride and 0.54g of benzoic acid and dissolve in 1mL of DMF, place it in 120°C for 1 hour after ultrasonication for 15 minutes, then take 8mg of TBAPy and add it into 1mL DMF solution for 15 minutes, then add TCPP solution into tetrachloride Zirconium chloride / benzoic acid solution, ultrasonic for 5 minutes, and the above solution was placed at 120°C for 30 minutes to obtain a NU-1000 precursor solution for use. The gas phase auxiliary solution is DMF.

[0060] The gold flake substrate (1cm×1cm) was firstly ultrasonicated with acetone, 2M hydrochloric acid, and distilled water for 5 minutes, blown dry with nitrogen gas, soaked in 11-mercapto-undecanol ethanol solution, and modified for 1 day to obtain hydroxyl-modified gold flakes base.

[0061] Take an airtight high-temperature-resistant glass bottle as a reaction vessel, put the base sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com