SiO2-coated ZnO super-hydrophobic coating material with micro-nano coarse structure, and preparation method, application and use method of SiO2-coated ZnO super-hydrophobic coating material

A rough structure, super-hydrophobic technology, applied in the direction of coating, etc., can solve the problems of unfavorable long-term protection and single performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

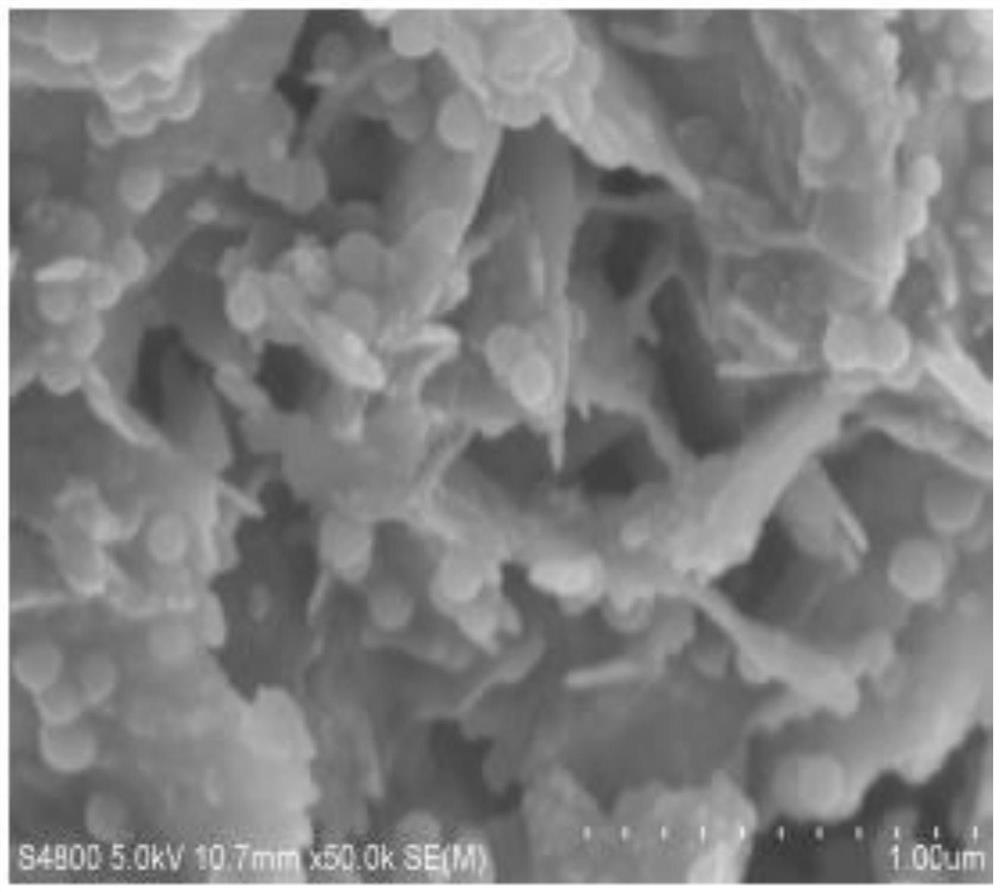

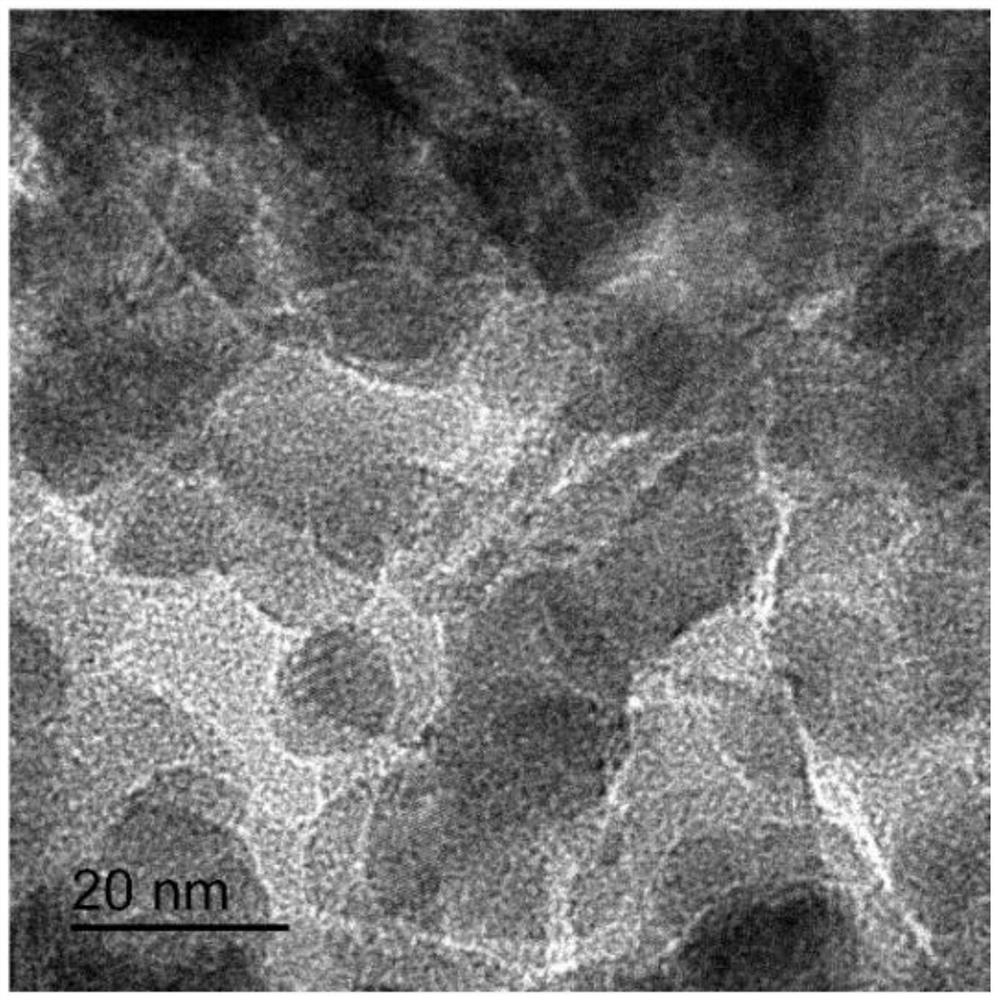

[0026] The preparation method of SiO2@ZnO superhydrophobic coating material with micro-nano-level rough structure of the present invention, the steps include: 1) Powder mixing: mix zinc oxide and silicon dioxide in proportion, according to 4.3-17.5mg / Add an organic solvent to the concentration of ml, and ultrasonically mix for 45-80 minutes; in terms of mass percentage, the amount of zinc oxide added is 30% to 64% of the sum of the mass of zinc oxide and silicon dioxide;

[0027] 2) Cross-linking reaction and surface modification treatment: add silane coupling agent to carry out cross-linking reaction under stirring state, reaction temperature is 28-40°C, stirring time is 45-85min; The mass-to-volume ratio of the volume of the coupling agent added is 0.86-2.5g / ml to determine the volume of the silane coupling agent added;

[0028] Add fluorocarbons in the stirring state to modify the surface to obtain the coating material stock solution, stirring time 2.5-4h; the mass volume ...

Embodiment 1

[0032] 1): powder mixing

[0033] Weigh 200 mg of zinc oxide and 250 mg of silicon dioxide and mix them, add 60 mL of ethanol, and sonicate for 60 min to obtain a mixed solution.

[0034] 2): Cross-linking reaction and surface modification treatment

[0035] Place the mixed solution obtained in step 1) and stir it on a magnetic stirrer at a speed of 500 rpm and a temperature of 35°C. Add 320 μL of silane coupling agent for cross-linking reaction and stir for 60 minutes; then add 330 μL of fluorocarbon for surface modification treatment and magnetically stir After 3.5 hours, the composite stock solution of SiO2@ZnO superhydrophobic coating material with micro-nano-scale rough structure was obtained.

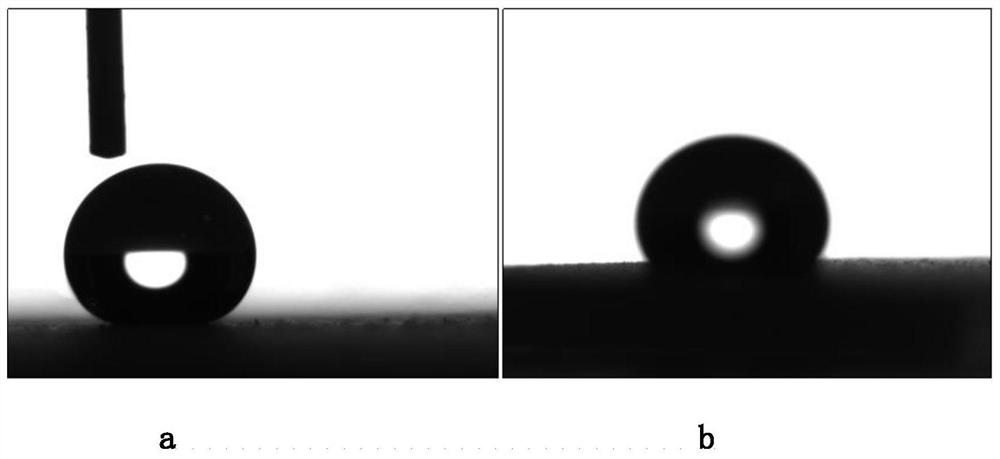

[0036] Spray the prepared SiO2@ZnO superhydrophobic coating material composite stock solution with micro-nano-scale rough structure on cultural relics protection or outdoor and indoor buildings, and its use method:

[0037] Clean and pre-treat the substrates to be coated: substr...

Embodiment 2

[0040] 1): powder mixing

[0041]Weigh 200 mg of zinc oxide and 300 mg of silicon dioxide and mix them, add 62 mL of ethanol, and sonicate for 50 min to obtain a mixed solution.

[0042] 2): Cross-linking reaction and surface modification treatment

[0043] Place the mixed solution obtained in step 1) on a magnetic stirrer for stirring at a speed of 550 rpm and a temperature of 35°C, add 300 μL of silane coupling agent for cross-linking reaction, stir for 60 min; then add 320 μL of fluorocarbon for surface modification treatment, and stir for 3 h , to obtain a composite stock solution of SiO2@ZnO superhydrophobic coating material with micro-nano-scale rough structure.

[0044] Spray the prepared SiO2@ZnO superhydrophobic coating material composite stock solution with micro-nano-scale rough structure on cultural relics protection or outdoor and indoor buildings, and its use method:

[0045] Cleaning and pretreatment of the substrate to be coated: the substrates to be coated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com