Soft-outside and rigid-inside oil-based drilling fluid nano blocking agent and oil-based drilling fluid

A technology of oil-based drilling fluid and nano-plugging agent, applied in the field of oil-based drilling fluid, can solve problems such as wellbore instability, and achieve the effects of enhancing salt resistance, good compatibility, and strong temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

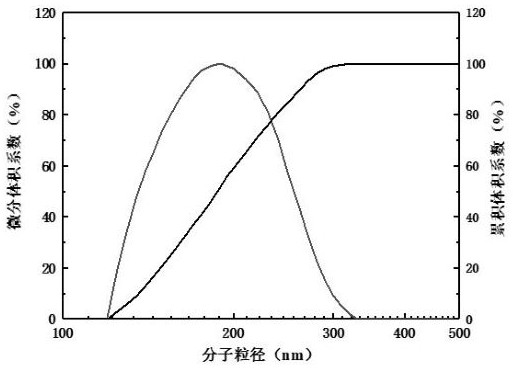

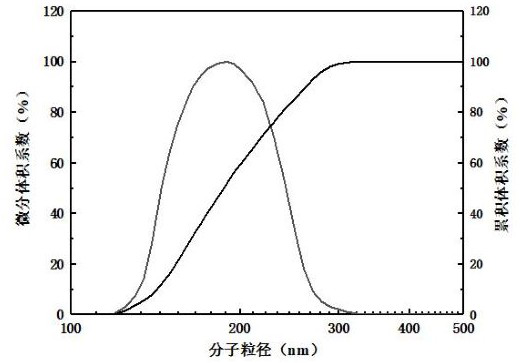

Image

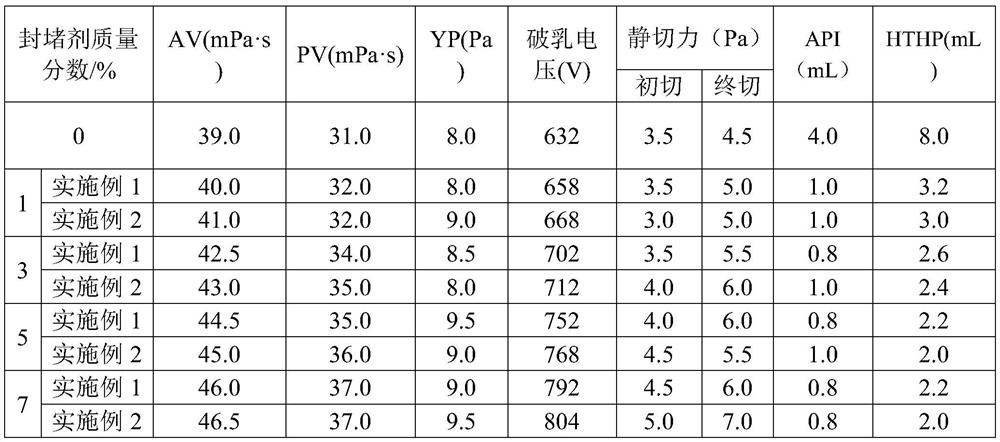

Examples

Embodiment 1

[0023] Modification of rigid materials: First, 5g of graphene oxide was added to 150mL of deionized water in a 250mL round-bottomed three-neck flask, and the mixture was dispersed by ultrasonic dispersion for 30min, then, 15ml of 3-(methacryloyloxy)propyl trimethyl Oxysilane and 5 drops of NH 3 ·H 2 O into the dispersion, the mixture was stirred at room temperature at a stirring speed of 400 rpm for 30 min, then the flask was immersed in a water bath at 60 °C, and stirred at the same stirring speed for 2 h, finally, the mixture was centrifuged and washed with ethanol and deionized water to remove Impurities were removed, and vacuum-dried at 60° C. for 24 hours, and then ground and dispersed to obtain a solid sample of the modified nano rigid material.

[0024] Synthesis of oil-based drilling fluid nano-sealing agent that is soft on the outside and rigid on the inside: First, introduce 125ml of deionized water into a 250ml round-bottomed three-neck bottle, add 2.5g of modified...

Embodiment 2

[0026] Modification of rigid materials: First, 5g of graphene oxide was added to 150mL of deionized water in a 250mL round-bottomed three-neck flask, and the mixture was dispersed by ultrasonic dispersion for 30min, then, 15ml of 3-(methacryloyloxy)propyl trimethyl Oxysilane and 5 drops of NH 3 ·H 2 O into the dispersion, the mixture was stirred at room temperature at a stirring speed of 400 rpm for 30 min, then the flask was immersed in a water bath at 60 °C, and stirred at the same stirring speed for 2 h, finally, the mixture was centrifuged and washed with ethanol and deionized water to remove Impurities were removed, and vacuum-dried at 60° C. for 24 hours, and then ground and dispersed to obtain a solid sample of modified nano-graphene oxide.

[0027] Synthesis of oil-based drilling fluid nano-sealing agent that is soft on the outside and rigid on the inside: First, introduce 125ml of deionized water into a 250ml round-bottomed three-neck bottle, add 2.5g of modified gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com