a k 2 sif 6 :mn 4+ Preparation method of nano phosphor powder

A nano-fluorescent powder and matrix technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as failure to meet application requirements, environmental and personnel damage, etc., and achieve increased luminous intensity, increased nucleation rate, and improved absorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] a kind of K 2 SiF 6 :Mn 4+ The preparation method of nanometer phosphor body, comprises the following steps:

[0030] (1) Weigh tetraethyl orthosilicate and surfactant and dissolve in commercially pure ethanol, and after fully stirring, A liquid is obtained. Among them, the molar concentration of tetraethyl orthosilicate dissolved in ethanol is 0.042mmol / ml~0.256mmol / ml, and the mass concentration of surfactant dissolved in ethanol should not be greater than 0.003g / ml.

[0031] It should be noted that the added surfactant can make K 2 SiF 6 :Mn 4+ Changes in the morphology of powder particles will also affect the uniformity, dispersion and particle size of the particles. It should be understood that the addition of surfactant is not necessary. However, surfactants can be added, depending on the properties of different surfactants, for K 2 SiF 6 : Mn 4+ The morphology, uniformity, dispersion and particle size of powder particles will have different effects.

[0...

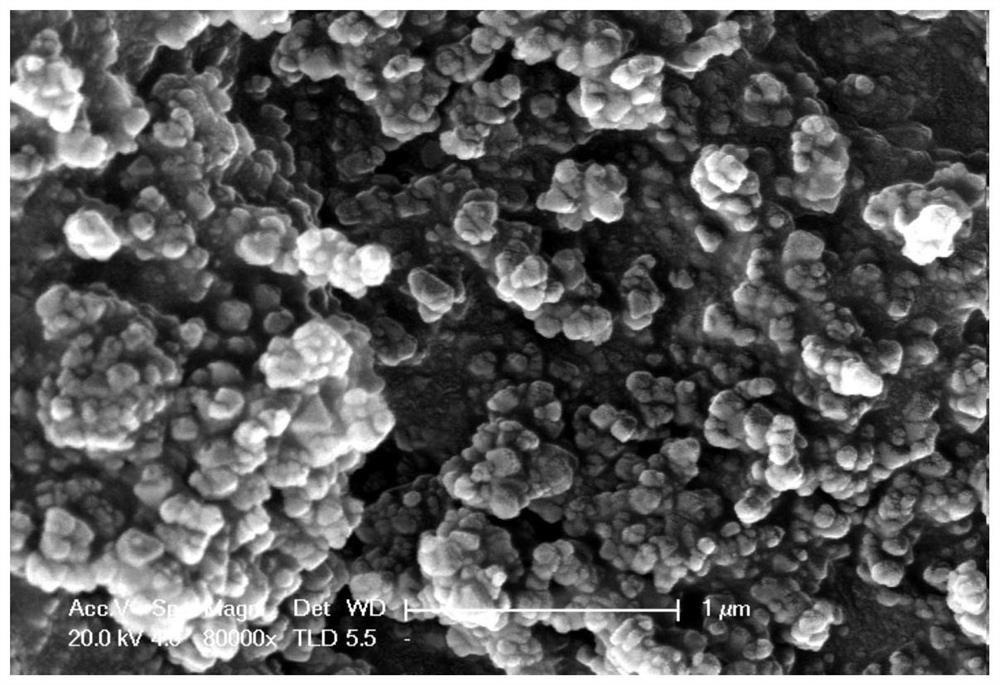

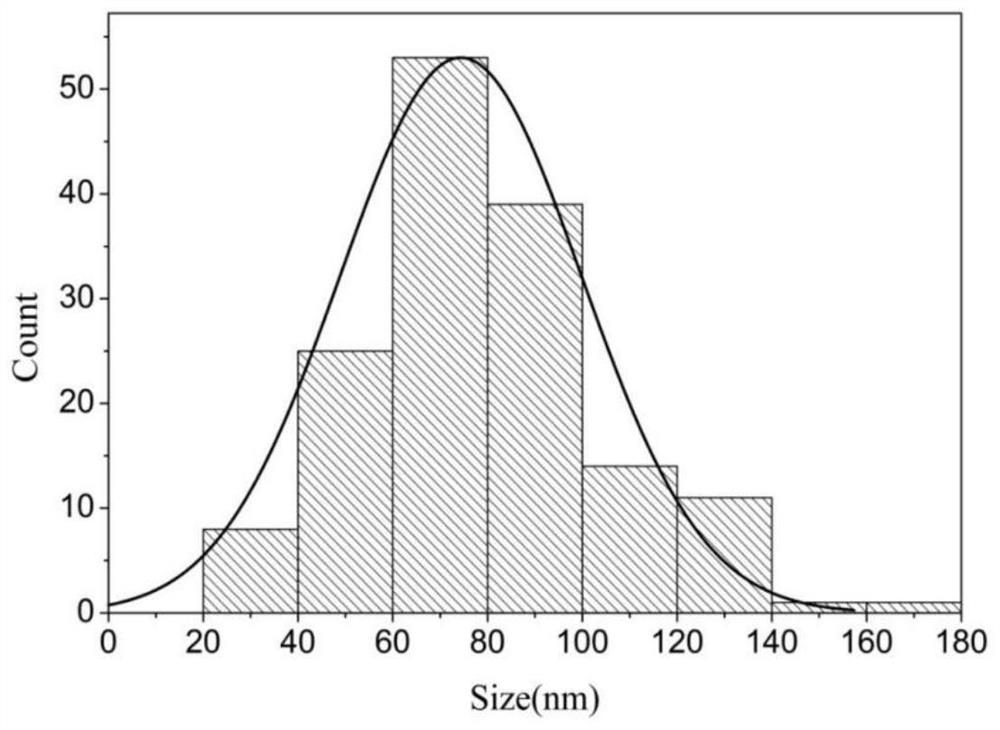

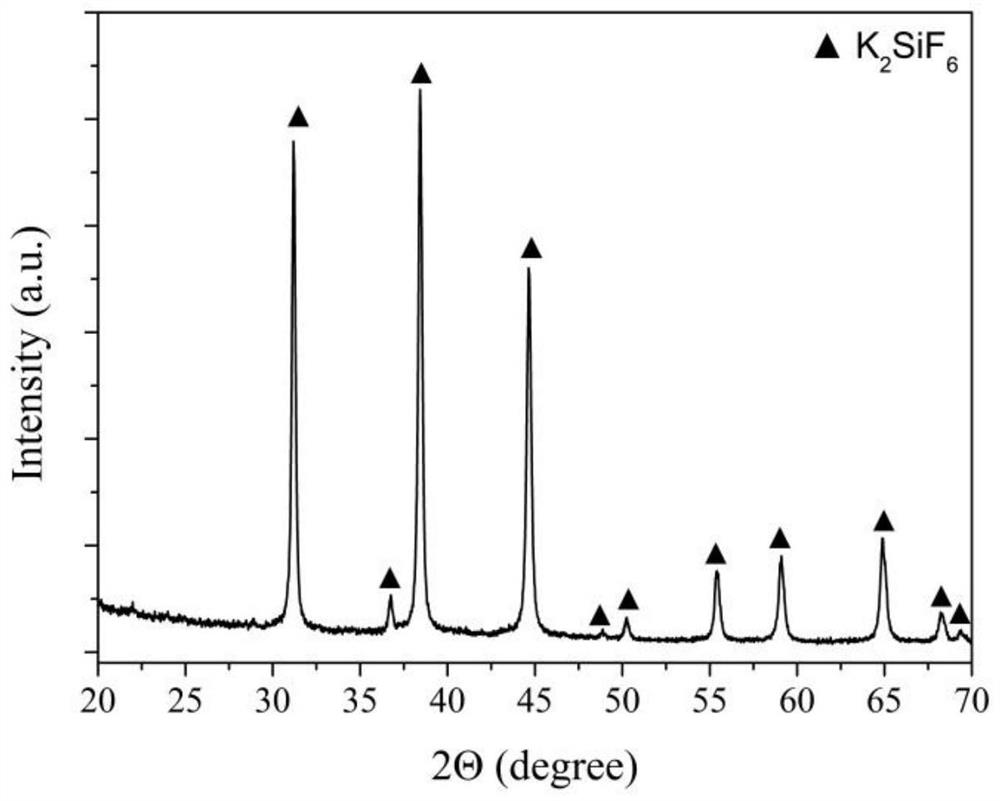

Embodiment 1

[0047] Weigh 1.55g of tetraethyl orthosilicate and 0.1g of polyvinylpyrrolidone, dissolve them in 30ml of absolute ethanol, put them in a water bath at 0°C, and the obtained solution is called solution A. Weigh 2.16g of KF and dissolve it in 15ml of pure acetic acid, put it in a water bath at 0°C, and call it solution B. Using a syringe that can control the titration rate, drop solution A into solution B that is stirred at 600 r / min at a rate of 2 ml / min. After the solution is completely dripped, continue to stir and age for 10 minutes. The obtained precipitate was washed three times with ethanol. Put the obtained precipitate into a freeze-drying box for 12 hours to obtain nano-K 2 SiF 6 powder.

[0048] After the hydrofluoric acid (49wt%) of 10ml is mixed with the sulfuric acid (49wt%) of 5ml, add the K of 0.17g 2 MnF 6 , stirred for 10 minutes to fully dissolve it. Weigh the K of the small particle size obtained by the above steps 2 SiF 6 1.5g of powder was added in...

Embodiment 2

[0050] Weigh 1.6 g of tetraethyl orthosilicate and 0.1 g of polyethylene glycol, dissolve in 30 ml of absolute ethanol, and place in a water bath at 30° C. The resulting solution is called solution A. Weigh 1.5g of KF and dissolve it in 15ml of pure acetic acid in a 30°C water bath, called solution B. Using a syringe that can control the titration rate, drop solution A into solution B that is stirred at 600 r / min at a rate of 2 ml / min. After the solution is completely dripped, continue to stir and age for 30 minutes. The obtained precipitate was washed three times with ethanol. Put the obtained precipitate into a freeze-drying box for 12 hours to obtain nano-K 2 SiF 6 powder.

[0051] After the hydrofluoric acid (49wt%) of 10ml is mixed with the sulfuric acid (50wt%) of 5ml, add the K of 0.17g 2 MnF 6 , stirred for 10 minutes to fully dissolve it. Weigh the K of the small particle size obtained by the above steps 2 SiF 6 1.5g of powder was added into the solution, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com