Nitrogen-containing natural gas membrane separation process with low-temperature enhancement of permeation selectivity

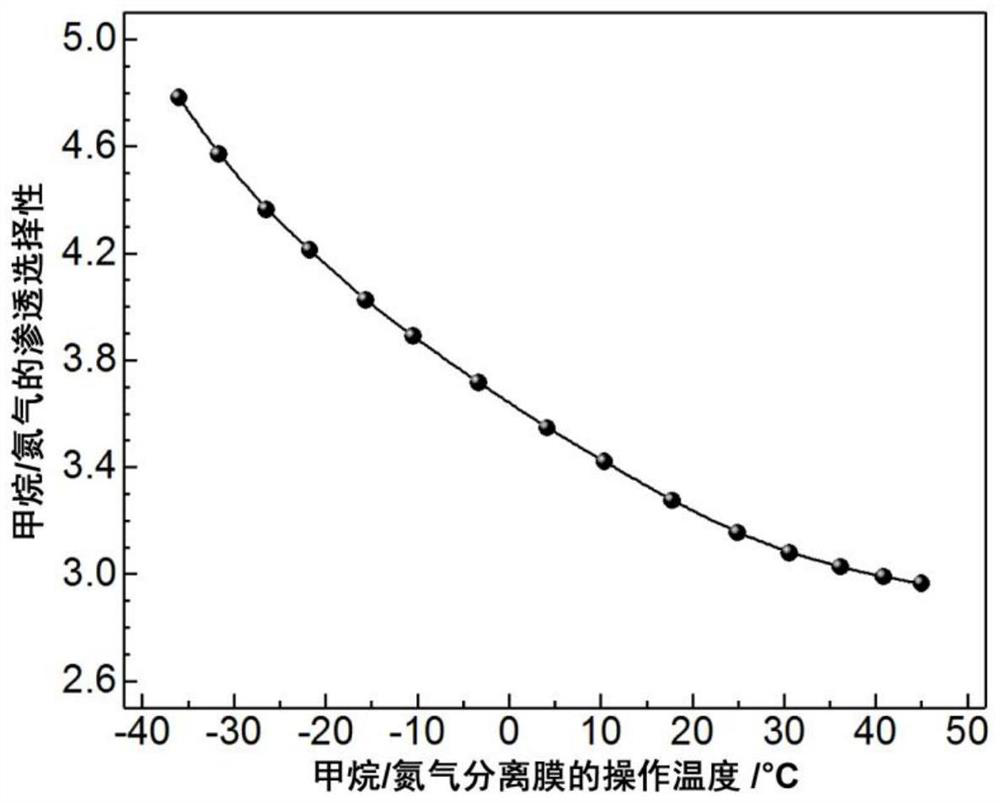

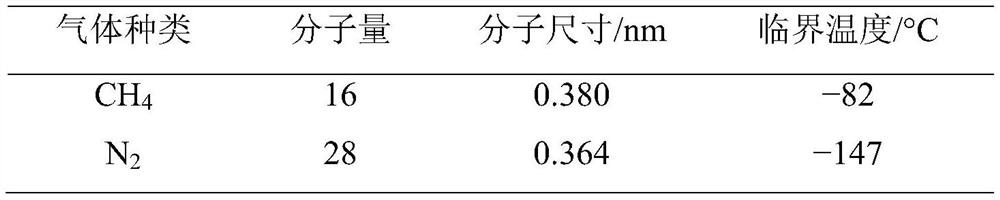

A low-temperature strengthening, membrane separation technology, applied in separation methods, dispersed particle separation, gas fuel and other directions, to achieve the effect of improving permeation selectivity, improving separation efficiency, and improving methane recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

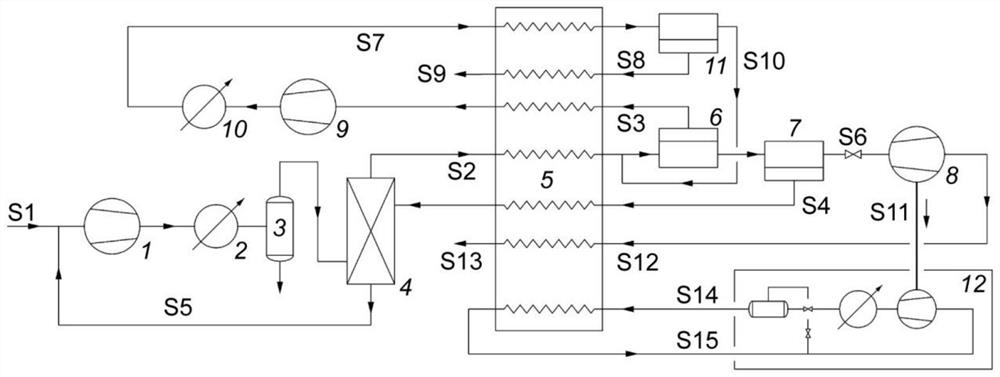

[0019] Example 1 field for a field of high-pressure nitrogen gas flooding EOR oil by-product process embodiment associated gas (carbon dioxide has been removed), the nitrogen content 29.23vol%, a water content 2.55vol%, the total content of hydrocarbons such as methane is 68.21vol%, the average for the associated gas flow 2000Nm 3 / h, using the multi-technical integration process including gas film separation, adsorption dehydration, turbine expansion, and steam compression refrigeration, in principle figure 1 As shown, concentrated methane is separated in high efficiency and high yield to produce commercial natural gas that meets the national standard "GB17820-2012".

[0020] Nitrogen-containing gas (S1) after removal of carbon dioxide, first entering the first compressor (1), boost to 1.80 MPAg, enter the first cooler (2), cool to normal temperature, enter the gas-liquid separation can (3) The condensed water is separated; the gas eliminates the top of the gas-liquid separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com