Sample preparation method and test method of glow discharge mass spectrometry ammonium paratungstate powder

A technology of glow discharge mass spectrometry and ammonium paratungstate, applied in the field of analytical chemistry, to shorten the analysis time, improve the accuracy, and avoid the introduction of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

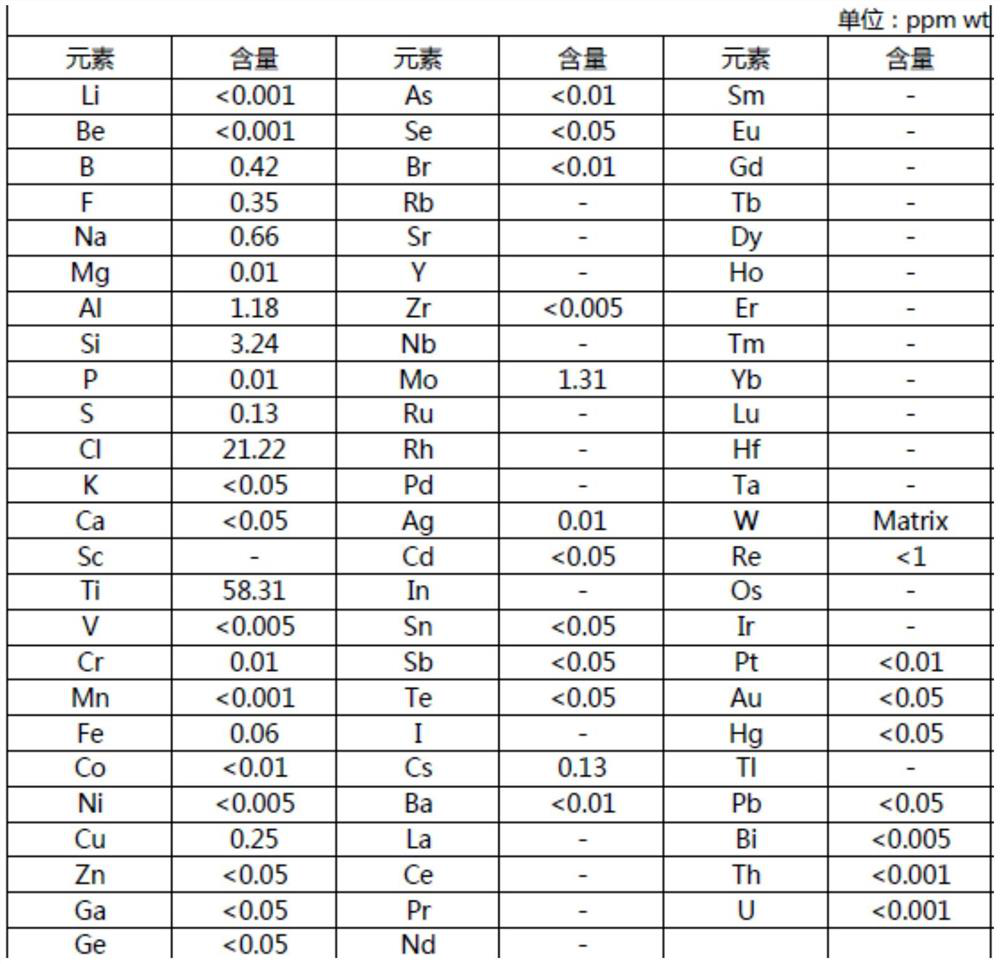

Image

Examples

Embodiment 1

[0036] The present embodiment provides a sample preparation method of ammonium paratungstate powder for glow discharge mass spectrometry, the method comprising:

[0037] The metal thallium is used to rotate the surface of the high-purity indium sheet to create a groove, the diameter of the groove is 0.6mm, and the depth is 0.2mm;

[0038] The indium sheet is placed in a polytetrafluoroethylene container, the indium sheet is cleaned with nitric acid for 3 minutes, rinsed with deionized water for 3 times, finally cleaned with absolute ethanol, and dried for use;

[0039] Use a mixed solution of nitric acid and hydrofluoric acid with a molar ratio of 1:0.8 to clean the polytetrafluoroethylene spatula for 3 minutes, then rinse it with deionized water for 3 times, and finally clean it with absolute ethanol;

[0040] Use the cleaned polytetrafluoroethylene spatula to transfer the ammonium paratungstate powder into the groove, and use a press to compact at 8 MPa for 12 minutes to obt...

Embodiment 2

[0042] The present embodiment provides a sample preparation method of ammonium paratungstate powder for glow discharge mass spectrometry, the method comprising:

[0043] Metal thallium is used to rotate and open grooves on the surface of high-purity indium sheets. The diameter of the grooves is 0.8mm and the depth is 0.4mm;

[0044] The indium sheet is placed in a polytetrafluoroethylene container, the indium sheet is cleaned with nitric acid for 3 minutes, rinsed with deionized water for 3 times, finally cleaned with absolute ethanol, and dried for use;

[0045] Use a mixed solution of nitric acid and hydrofluoric acid with a molar ratio of 1:1.2 to clean the polytetrafluoroethylene spatula for 3 minutes, then rinse it with deionized water for 3 times, and finally clean it with absolute ethanol;

[0046] Use the cleaned polytetrafluoroethylene spatula to transfer the ammonium paratungstate powder into the groove, and use a press to compact it at 12MPa for 8 minutes to obtain th...

Embodiment 3

[0048] The present embodiment provides a sample preparation method of ammonium paratungstate powder for glow discharge mass spectrometry, the method comprising:

[0049] Metal thallium is used to rotate and open grooves on the surface of high-purity indium sheets. The diameter of the grooves is 0.7mm and the depth is 0.3mm;

[0050] The indium sheet is placed in a polytetrafluoroethylene container, the indium sheet is cleaned with nitric acid for 3 minutes, rinsed with deionized water for 3 times, finally cleaned with absolute ethanol, and dried for use;

[0051] Use a mixed solution of nitric acid and hydrofluoric acid with a molar ratio of 1:1 to clean the polytetrafluoroethylene spatula for 3 minutes, then rinse it with deionized water for 3 times, and finally clean it with absolute ethanol;

[0052] Use the cleaned polytetrafluoroethylene spatula to transfer the ammonium paratungstate powder into the groove, and use a press to compact at 10 MPa for 10 minutes to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com