A positive electrode for a nickel-hydrogen secondary battery, a preparation method thereof, and a nickel-hydrogen secondary battery

A secondary battery and positive electrode technology, applied in the field of new electrochemical energy storage, can solve the problems of limiting the development of nickel-metal hydride batteries, poor conductivity of positive electrodes, slow kinetics, etc., and achieve excellent cycle life, rate performance improvement, and promotion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing the positive electrode for the above-mentioned nickel-hydrogen secondary battery, comprising the following steps:

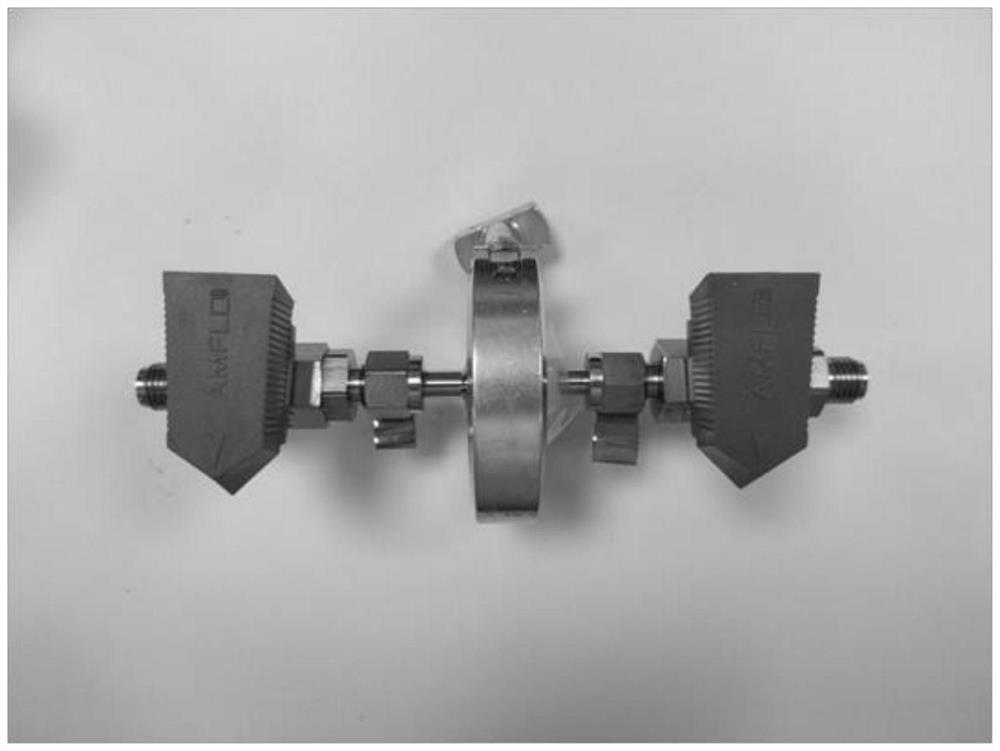

[0044] A mixed solution of cobalt nitrate, nickel nitrate and sodium hypophosphite is used as the electrolyte, and a phosphorus-doped nickel-cobalt mixed positive electrode material layer is deposited on the surface of the positive electrode substrate by dynamic electrochemical deposition to obtain a positive electrode for a nickel-hydrogen secondary battery.

[0045] The invention adopts the dynamic electrochemical deposition method, that is, the cyclic voltammetry method to prepare the positive electrode. Wherein, a mixed solution formed by cobalt nitrate, nickel nitrate and sodium hypophosphite is used as the electrolyte. In the electrolyte, the concentration of cobalt nitrate is 0.001mol / L~10mol / L, preferably 0.001mol / L, 0.01mol / L, 0.1mol / L, 0.5mol / L, 1.0mol / L, 5mol / L , 10mol / L, or any value b...

Embodiment 1

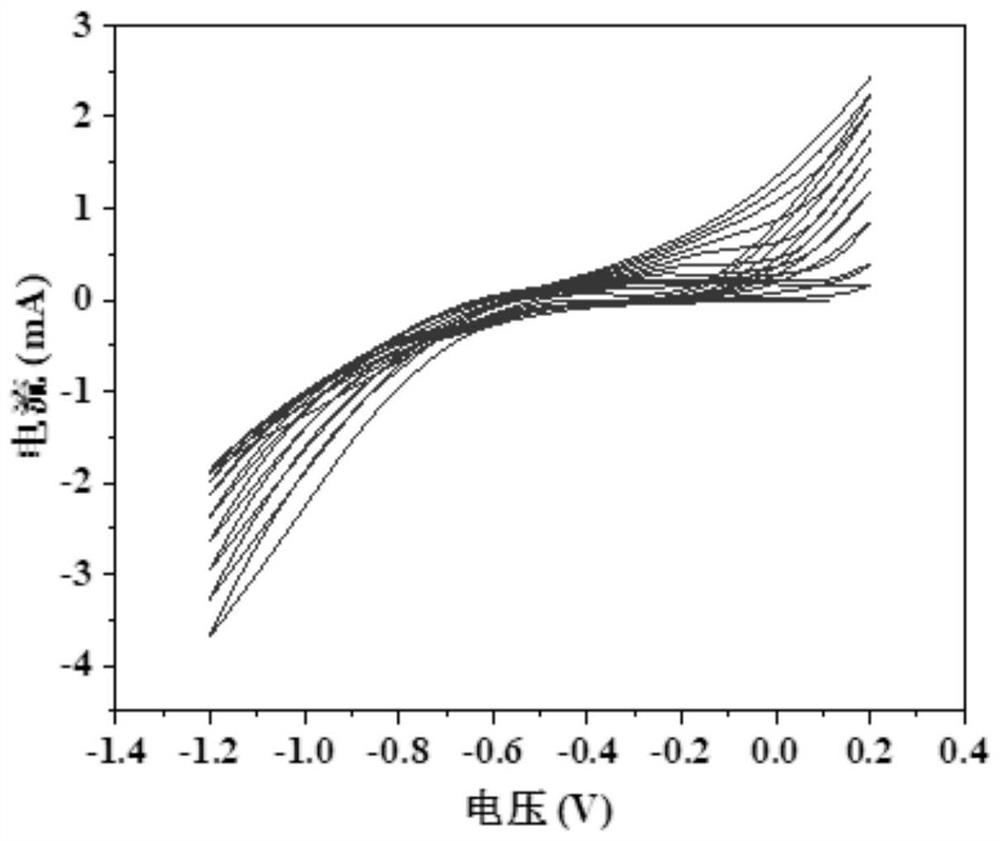

[0070] Using foamed nickel as the working electrode, Ag / AgCl as the reference electrode, and platinum sheet as the counter electrode in a mixed solution of 0.1 mol / L cobalt nitrate, 0.1 mol / L nickel nitrate, and 0.05 mol / L sodium hypophosphite Electrodeposition is performed for 10 cycles, and the current-voltage curve during the deposition process is as follows figure 2 As shown, the deposition voltage is -1.2V to 0.2V, and the deposition current is in the range of -4mA to 2.5mA.

Embodiment 2

[0072] Using carbon cloth as the working electrode, Ag / AgCl as the reference electrode, and platinum sheet as the counter electrode in a mixed solution of 0.1mol / L cobalt nitrate, 0.2mol / L nickel nitrate, and 0.05mol / L sodium hypophosphite Electrodeposition was carried out for 10 cycles, and the current-voltage curve during the deposition process was the same as figure 2 Similarly, this method has no substrate dependence and is universal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com