Composite solid electrolyte, preparation method thereof and solid-state battery

A solid electrolyte and electrolyte technology, applied in the direction of electrolyte immobilization/gelation, secondary batteries, secondary battery repair/maintenance, etc., can solve the problem of low ionic conductivity, high cost of inorganic sulfide electrolytes, and poor practicability And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

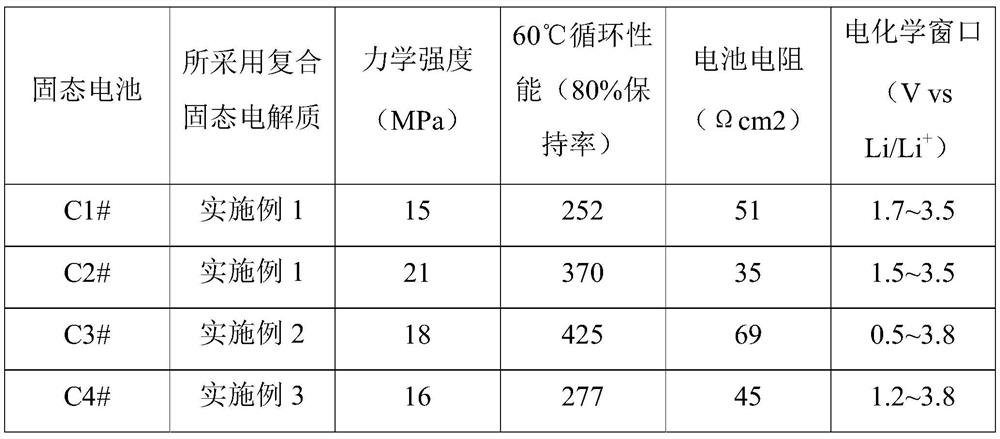

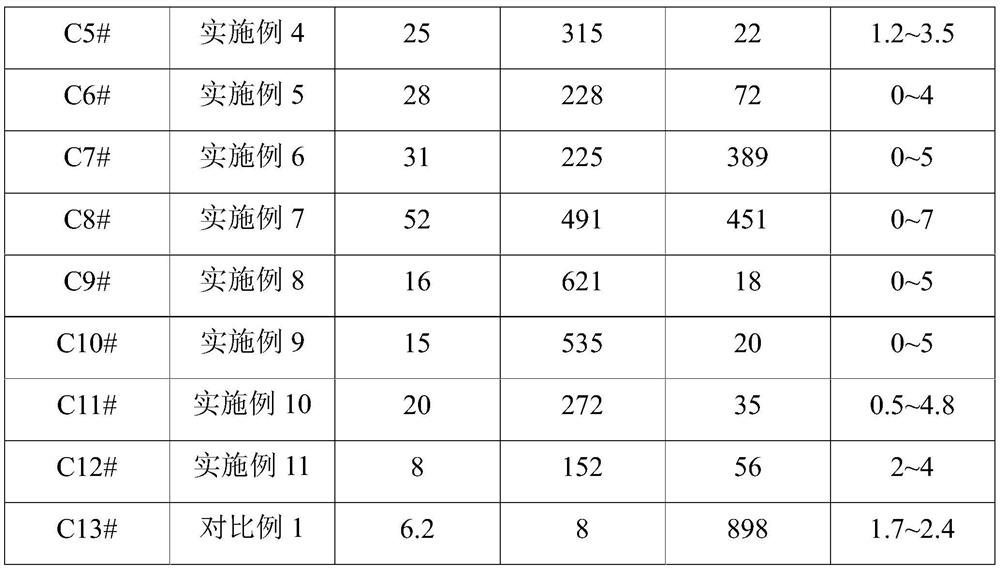

Examples

Embodiment 1

[0017] In this example, a composite solid electrolyte is prepared, and the specific process includes the following steps:

[0018] S1, get the raw material components according to the following ratio: 20wt% lithium salt LiTFSI, 60wt% polysulfide (structural formula is ) and 20wt% inorganic sulfide electrolyte LGPS (Li10GeP2S12);

[0019] S2. Add the lithium salt LiTFSI into the organic solvent acetonitrile. After fully stirring and dissolving, add polysulfide and LGPS in sequence, and after ultrasonic dispersion, stir at 1200r / min for 2h to obtain a composite electrolyte slurry, and then cast it in a mold for 60 After heating and drying at ℃ for 24 hours, a composite solid electrolyte was obtained.

Embodiment 2

[0021] In this example, a composite solid electrolyte is prepared, and the specific process includes the following steps:

[0022] S1, get the raw material components according to the following ratio: 20wt% lithium salt LiTFSI, 60wt% polysulfide (structural formula is ) and 20wt% binary sulfide electrolyte Li 2 S-P 2 S 5 ;

[0023] S2. Add lithium salt LiTFSI into the organic solvent acetonitrile, stir and dissolve, then add polysulfide and Li 2 S-P 2 S 5 , and ultrasonically dispersed, stirred at 1200r / min for 2h to obtain a composite electrolyte slurry, and then cast in a mold, heated and dried at 60°C for 24h to obtain a composite solid electrolyte.

Embodiment 3

[0025] In this example, a composite solid electrolyte is prepared, and the specific process includes the following steps:

[0026] S1, get the raw material components according to the following ratio: 20wt% lithium salt LiTFSI, 60wt% polysulfide (structural formula is ) and 20wt% ternary sulfide electrolyte Li 2 S-P 2 S 5 -SnS;

[0027] S2. Add the lithium salt LiTFSI into the organic solvent ethyl acetate, stir and dissolve, then add polysulfide and Li 2 S-P 2 S 5 -SnS, and ultrasonically dispersed, stirred at 1200r / min for 2h to obtain a composite electrolyte slurry, then cast in a mold, heated and dried at 60°C for 24h to obtain a composite solid electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com