Method for preparing honeycomb molecular sieve adsorbent from red mud

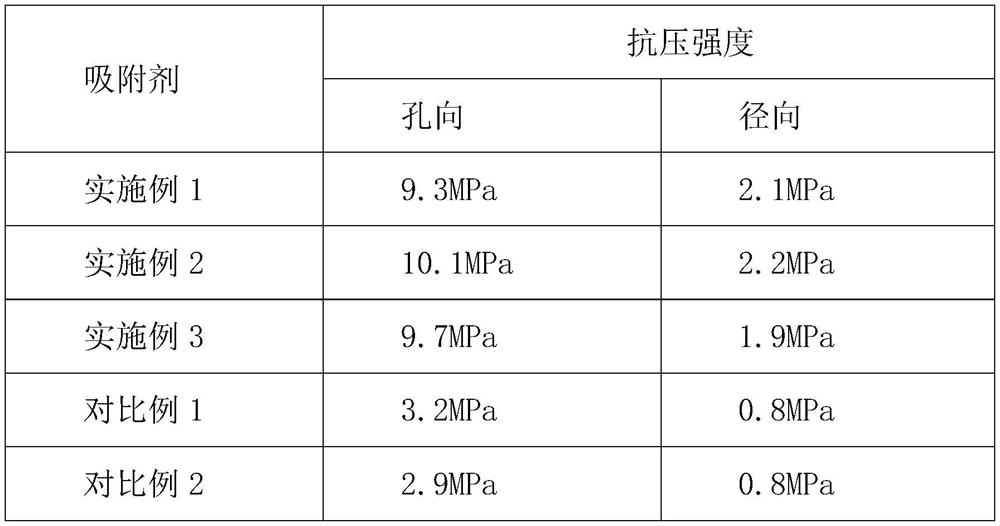

A molecular sieve and honeycomb technology, applied in the field of molecular sieves, can solve the problems of easy peeling off of the coating, impact, and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of method that the present invention proposes utilizes red mud to prepare cellular molecular sieve adsorbent, comprises the following steps:

[0031] S1, mixing: Put the raw molecular sieve powder, water, red mud, anti-crack glass fiber and citric acid into the mixer in proportion, and the mixer stirs each raw material for 1.5 hours to fully mix each raw material to obtain powder body;

[0032] S2, mud refining: put the powder, water, organic additives, plasticizer and dispersant into the mud refining machine in proportion, and process the powder into mud;

[0033] S3, forming: put the mud material into a vacuum extruder and extrude to form a honeycomb molecular sieve raw material, and the extrusion pressure is 8-10Mpa;

[0034] S4, drying: the formed honeycomb molecular sieve raw material is dried under reduced pressure at 20-80°C for 24 hours, and the power is 250W-650W;

[0035] S5, roasting: the dried honeycomb molecular sieve is heated up to 300°C at a hea...

Embodiment 2

[0038] A kind of method that the present invention proposes utilizes red mud to prepare cellular molecular sieve adsorbent, comprises the following steps:

[0039] S1, mixing: put the raw molecular sieve powder, water, red mud, anti-crack glass fiber and citric acid into the mixer in proportion, and the mixer stirs each raw material for 2 hours to fully mix each raw material to obtain a powder ;

[0040] S2, mud refining: put the powder, water, organic additives, plasticizer and dispersant into the mud refining machine in proportion, and process the powder into mud;

[0041] S3, molding: put the mud material into a vacuum extruder and extrude it to obtain a honeycomb molecular sieve raw material, and the extrusion pressure is 10-16Mpa;

[0042] S4, drying: the formed honeycomb molecular sieve raw material is dried under reduced pressure at 22-82°C for 18 hours, with a power of 300W-700W, until the water content is ≤5.0wt%;

[0043] S5, roasting: the dried honeycomb molecular s...

Embodiment 3

[0046] A kind of method that the present invention proposes utilizes red mud to prepare cellular molecular sieve adsorbent, comprises the following steps:

[0047] S1, mixing: Put the raw molecular sieve powder, water, red mud, anti-crack glass fiber and citric acid into the mixer in proportion, and the mixer stirs each raw material for 2.5 hours to fully mix each raw material to obtain powder body;

[0048] S2, mud refining: put the powder, water, organic additives, plasticizer and dispersant into the mud refining machine in proportion, and process the powder into mud;

[0049] S3, forming: put the mud material into a vacuum extruder and extrude to form a honeycomb molecular sieve raw material, and the extrusion pressure is 12-18Mpa;

[0050] S4, drying: the formed honeycomb molecular sieve raw material is dried under reduced pressure at 25-85°C for 16 hours, with a power of 350W-750W, until the water content is ≤4.0wt%;

[0051] S5, roasting: the dried honeycomb molecular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com