Method for preparing sulfurized ferroferric oxide complex by using solid raw material mechanochemical technology, and application of sulfurized ferroferric oxide complex

A technology of ferric sulfide sulfide and mechanochemical method, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. Advanced problems, to achieve the effect of convenient in-situ synthesis application, simple process and controllable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] It was prepared using a planetary ball mill sulfurized tri-iron tetroxide complexes, the following steps:

[0039] 1) The 50 stainless steel balls having a diameter of 6mm stainless steel bead mill pot was charged 45mL;

[0040] 2) Weigh 0.6g of elemental sulfur powder, and 1.4g triiron tetraoxide (accounting for 30% of sulfur powder) was placed in a ball mill jar, without protective atmosphere, temperature and pressure can be maintained;

[0041] 3) The mill speed was set 600rpm, 4H milling time is set;

[0042] 4) After completion of milling the material removed to give triiron tetroxide sulfide complex.

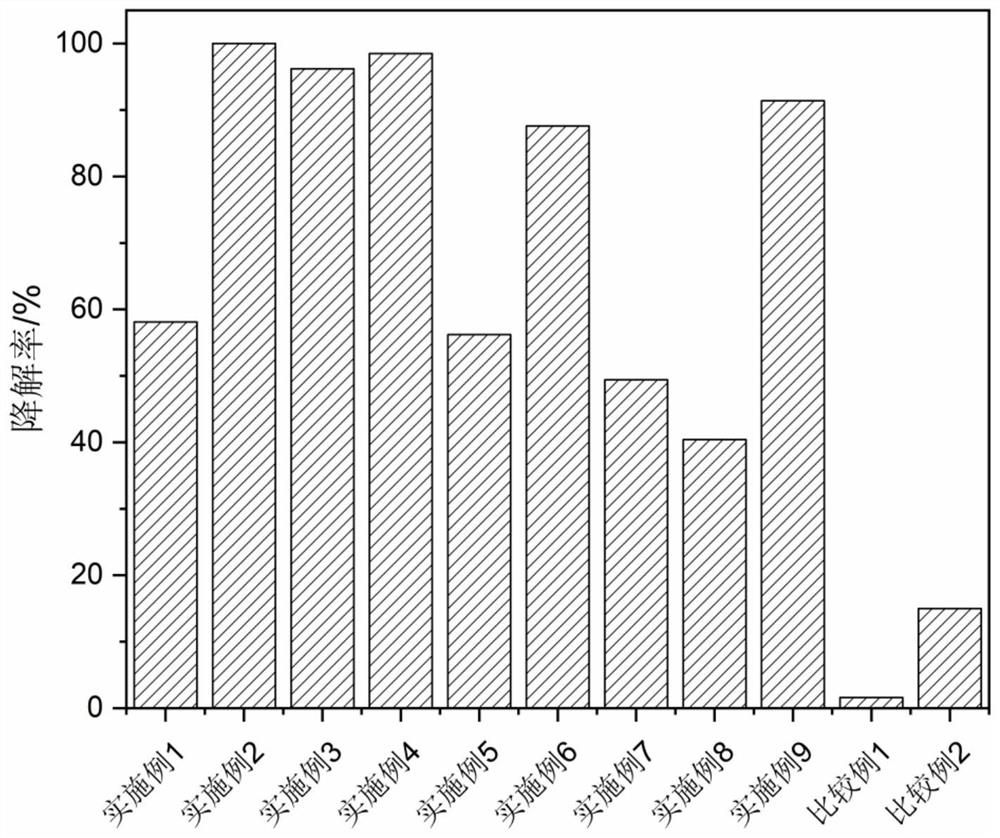

[0043] In a typical representative of 2,4-dichlorophenol, triiron tetroxide sulfide complex prepared activated investigated peroxomonosulfate activity and the ability to degrade the target pollutants.

[0044] In 100mL Erlenmeyer flask was added 15mg triiron tetroxide sulfide complex was added a solution of 50mL, wherein the PMS concentration is 1.0mM, 2,4-DCP concentrati...

Embodiment 2

[0047] It was prepared using a planetary ball mill sulfurized tri-iron tetroxide complexes, the following steps:

[0048] 1) The 50 stainless steel balls having a diameter of 6mm stainless steel bead mill pot was charged 45mL;

[0049] 2) Weigh 0.6g of elemental sulfur powder, and 1.4g triiron tetraoxide (accounting for 30% of sulfur powder) was placed in a ball mill jar, without protective atmosphere, temperature and pressure can be maintained;

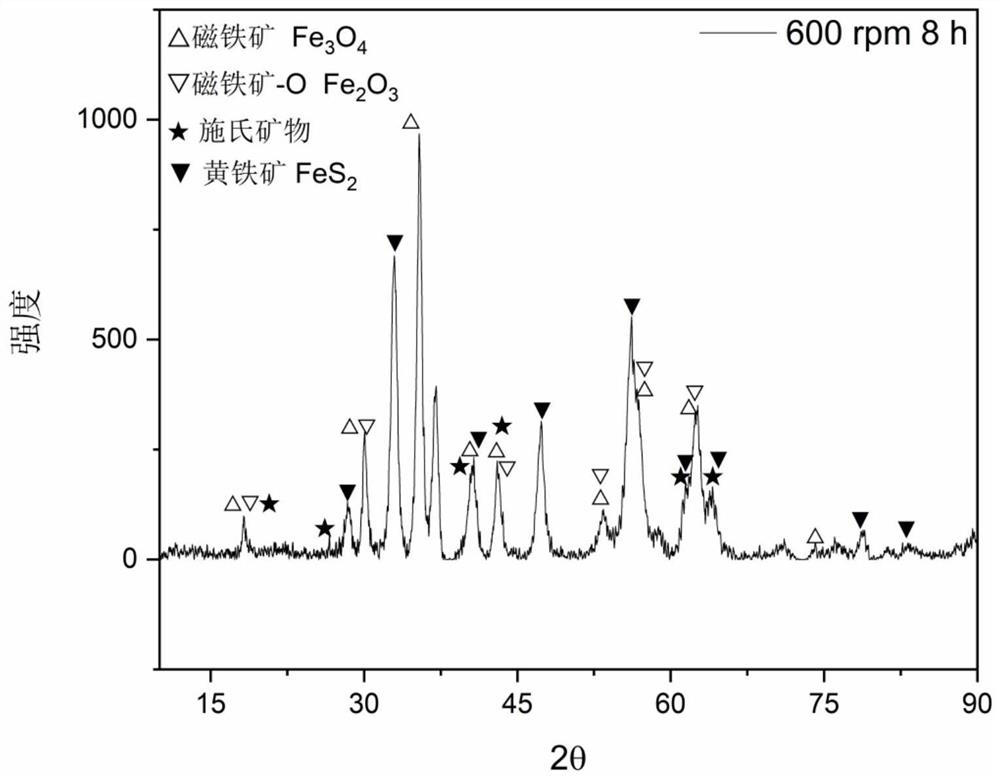

[0050] 3) The mill speed was set 600rpm, 8H milling time is set;

[0051] 4) After completion of milling the material removed to give triiron tetroxide sulfide complex.

[0052] In a typical representative of 2,4-dichlorophenol, triiron tetroxide sulfide complex prepared activated investigated peroxomonosulfate activity and the ability to degrade the target pollutants.

[0053] In 100mL Erlenmeyer flask was added 15mg triiron tetroxide sulfide complex was added a solution of 50mL, wherein the PMS concentration is 1.0mM, 2,4-DCP concentra...

Embodiment 3

[0057] Example 3 differs from the embodiment of Example 1 in that the milling time was 10h. The reaction conditions consistent reaction 5min, the degradation efficiency of 96.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com