High-activity aluminum oxide loaded platinum catalyst, preparation method and application thereof

A technology of alumina-loaded and platinum catalysts, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of insufficient activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare Pt / Al as follows 2 o 3 -P-CH 4 catalyst

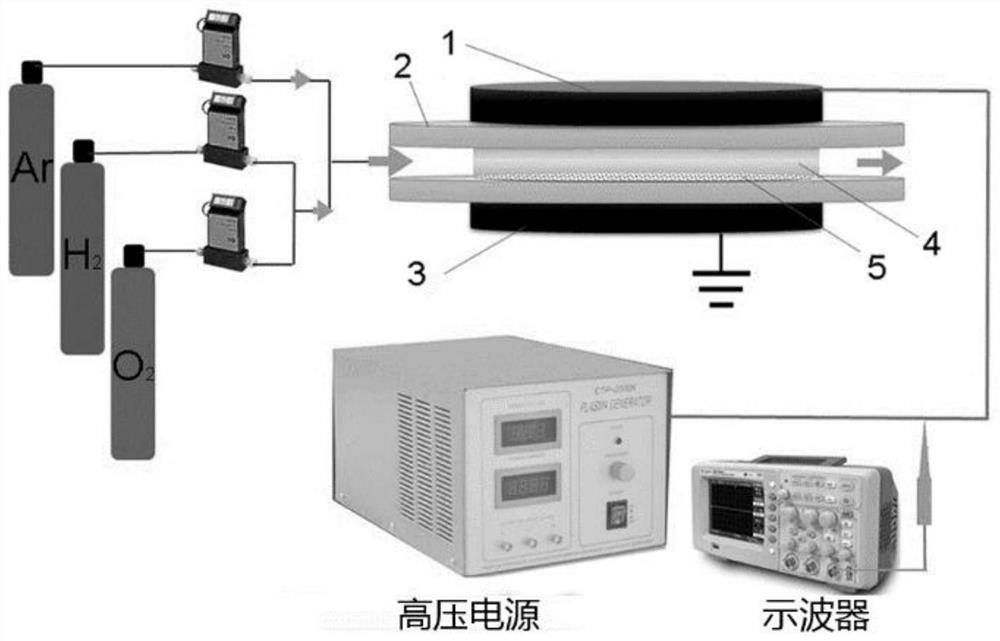

[0042] (1) Weigh 0.5gAl 2 o 3 And spread it in the plasma reactor, wherein the thickness of the quartz glass is 1mm, and the discharge gap is 8mm. Methane and argon flowed through the reactor at a flow rate of 50ml / min respectively, using a sinusoidal discharge, with a peak-to-peak voltage of 45kV, and a discharge time of 3 minutes each time, a total of 5 discharges, with an interval of 15 minutes between each two discharges The sample is stirred to obtain Al 2 o 3 -P-CH 4 ;

[0043] (2) Dilute H by equal volume impregnation 2 PtCl 6 solution impregnated in Al 2 o 3 -P-CH 4 (Pt content is 3wt%), dried at 80°C for 12 hours, and calcined at 400°C for 2 hours in a hydrogen atmosphere to obtain 3%Pt / Al 2 o 3 -P-H 2 catalyst.

[0044] Put 0.8g of the above catalyst into a 50ml high-pressure stirred reactor, put 10mL of perhydrogenated dibenzyltoluene, and pass through pure hydrogen for purging, the pressure i...

Embodiment 2

[0046] Prepare Pt / Al as follows 2 o 3 -P-CH 3 COOH catalyst:

[0047] Control the flow rate of argon flow to be 100ml / min to flow through the bubbler equipped with acetic acid, and then flow through the reactor. The rest of the preparation process and implementation process of the catalyst are the same as in Example 1.

[0048] In the catalytic reaction, the dehydrogenation rate was 74.2% in 5 hours, which was 18.5% higher than the 62.6% dehydrogenation rate of the catalyst without plasma treatment.

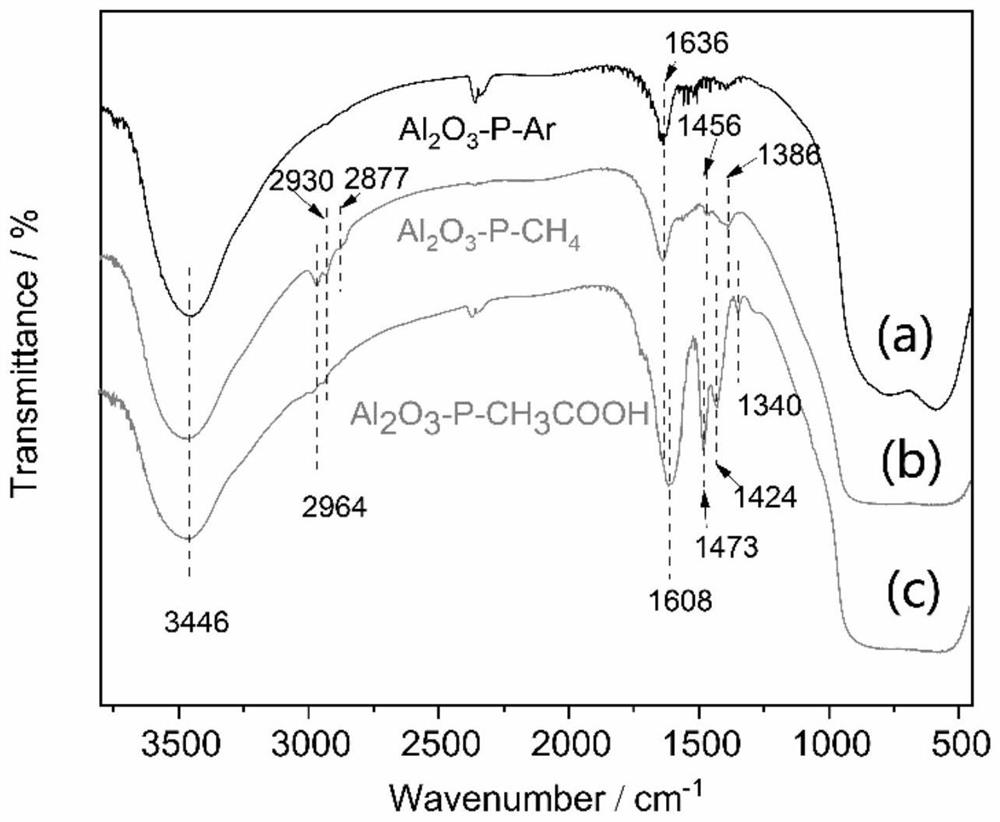

[0049] see figure 1 , the Pt / Al prepared by the present invention 2 o 3 -P-CH 4 Surface has methyl and methylene groups, Pt / Al 2 o 3 -P-CH 3 The surface of COOH has CH 3 COO-group and a small amount of methyl; figure 1 The middle (a) curve is used for comparison to illustrate that the carrier surface not using methane and acetic acid atmosphere dielectric barrier discharge plasma treatment does not contain related groups: figure 1 2964, 2930, 2877, 1456 and 1386cm in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com