Super-hydrophobic biological composite membrane, preparation method and application thereof

A biocomposite film and super-hydrophobic technology, applied in applications, chemical instruments and methods, household packaging, etc., can solve the problems of super-hydrophobic material surface easy to quickly restore hydrophilicity, long preparation process, and toxic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a superhydrophobic biocomposite film, comprising the following steps:

[0029] Coating the chitosan solution on the surface of the carrier to form a chitosan film layer;

[0030] Casting a sodium phytate solution on the surface of the chitosan film layer to form a sodium phytate layer;

[0031] Alternately repeating the processes of coating chitosan solution and casting sodium phytate solution, and then assembling layer by layer to obtain chitosan sodium phytate composite film;

[0032] First soak the chitosan sodium phytate composite film in the ZnO nanoparticle dispersion, after the first drying, soak the gained composite film in the stearic acid solution for the second time, and perform the second drying, alternately The process of first soaking-first drying and second soaking-second drying is repeated to obtain a super-hydrophobic biocomposite film.

[0033] Unless otherwise specified, the present invention has no spec...

Embodiment 1

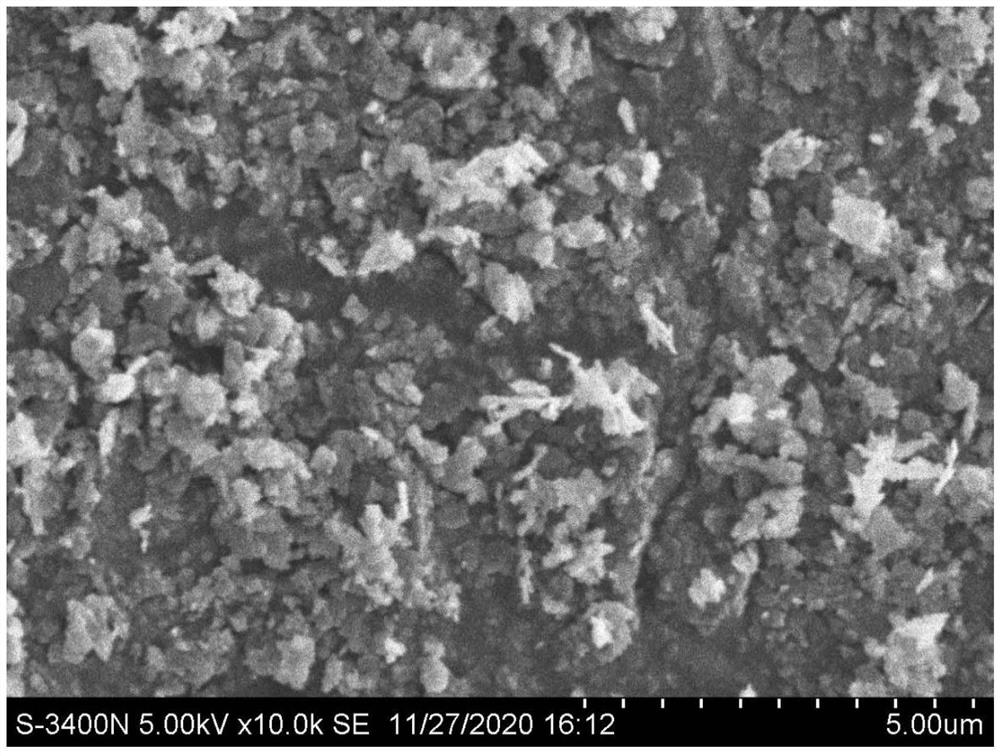

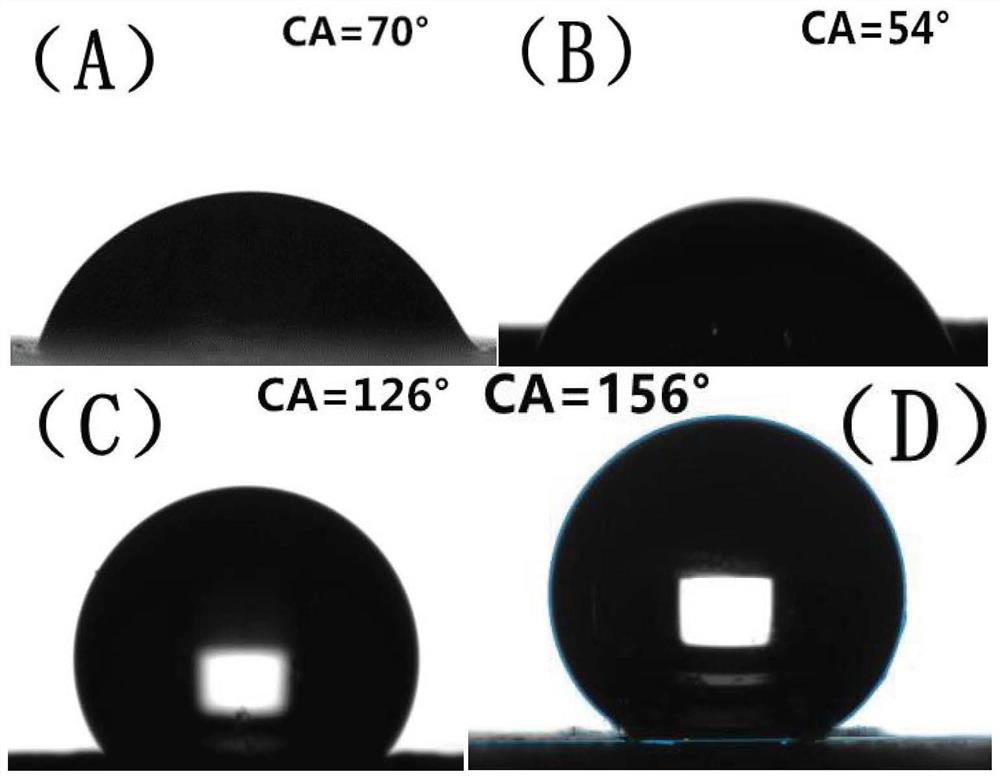

[0063] Take by weighing 3g chitosan and be dissolved in the acetic acid solution of 100mL 2%Vol (2mL anhydrous acetic acid is mixed with 100mL water to obtain), obtain the chitosan solution of 3wt.%; Take by weighing 1g sodium phytate and dissolve in 100mL water, obtain 1wt.% sodium phytate solution; 3mL chitosan solution is evenly coated on the surface of the glass slide to form a chitosan film layer, and then 1mL1wt% sodium phytate solution is cast on the surface of the chitosan film layer to form sodium phytate Repeat the process of coating chitosan solution and casting sodium phytate solution 9 times alternately, assemble layer by layer, dry the obtained composite film in an oven at 60°C overnight until the chitosan sodium phytate composite film is completely dry, and obtain Chitosan sodium phytate composite film, wherein chitosan film layer 5 layers, sodium phytate layer 4 layers (the thickness of each layer of chitosan film layer is 7 μm, the thickness of each layer of so...

Embodiment 2

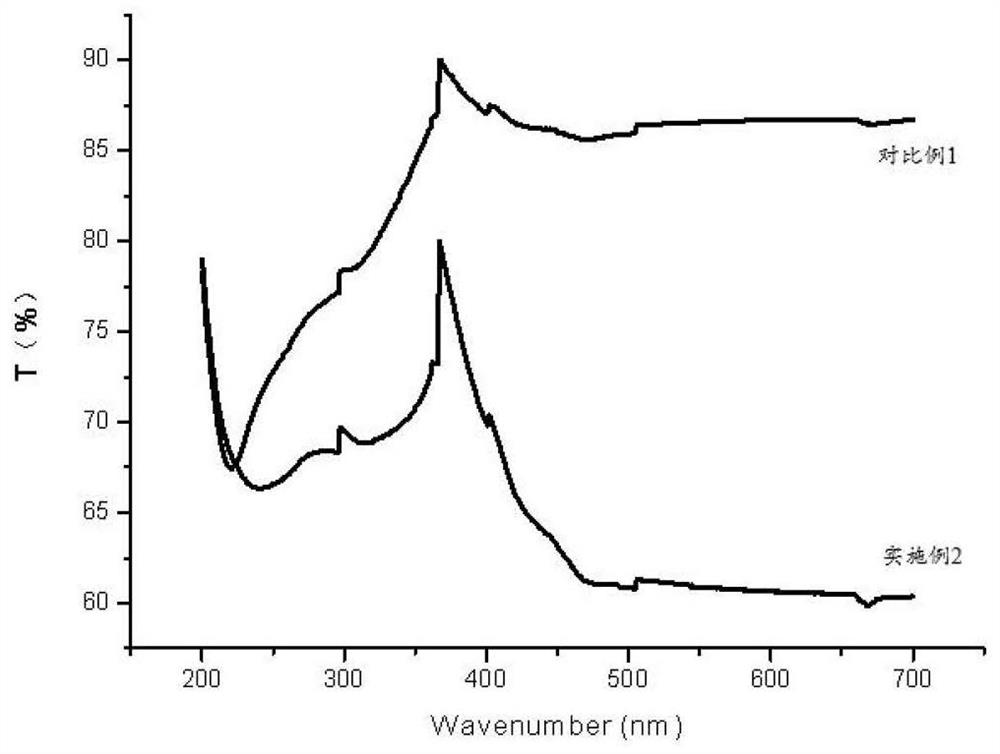

[0067] The 0.63wt.% ZnO nanoparticle dispersion in Example 1 was replaced by 1.26wt.% ZnO nanoparticle dispersion, and the rest were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com