Membrane slurry for implantable glucose sensor, and preparation method thereof

A glucose sensor and implantable technology, applied in the field of membrane slurry and its preparation, can solve the problems of reducing analyte concentration, increasing sensor production cycle and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

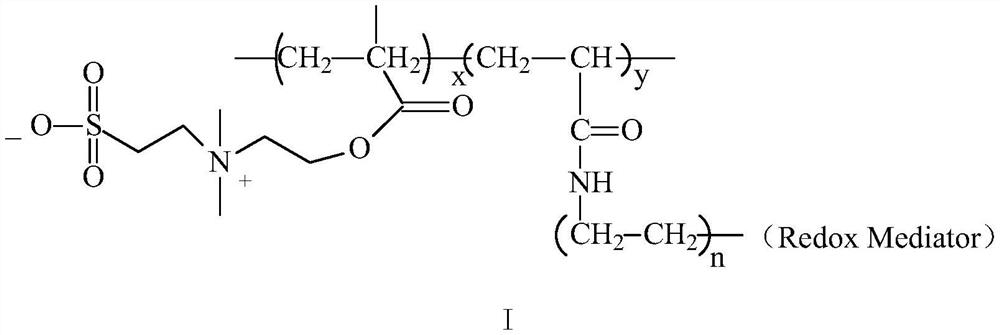

[0027] (1) Copolymerization of acrylic acid (AA) and thiobetaine methyl acrylate (SBMA) monomer solution: Weigh 2.21g of AA and 0.04g of SBMA monomer in turn in a polymerization bottle filled with a certain amount of 0.3M NaCl solution, shake to make it completely Dissolve, nitrogen gas at room temperature. After adding 0.0018g of potassium persulfate and sodium bisulfite (mass ratio: 2:1), the temperature was raised to a certain temperature (50°C), and the nitrogen flow was stopped after an obvious polymerization reaction occurred, and the reaction vessel was sealed. After 4 hours of reaction, the reaction was terminated with acetone. The product was soaked in acetone for 12 hours to remove unreacted monomers, and a white gel was obtained. After vacuum drying, a white powder was obtained. The product was about 1.7 g, and the yield was 76%. It was named p(SBMA-AA).

[0028] (2) Condensation and acylation reaction, take a 5mL centrifuge tube as the reaction vessel. First, p(S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com