A 3D printed artificial skull patch and preparation method thereof

A technology of 3D printing and patch, which is applied in the field of 3D printed artificial skull patch and its preparation, can solve the problems of increasing operation time, affecting the appearance, weakening the strength of titanium alloy mesh, etc., to solve the problem of biocompatibility , High matching degree of shape and size, and the effect of inducing bone cell growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a 3D printed artificial skull patch, specifically comprising the following steps:

[0038] 1. Data collection

[0039] Obtain the patient's preoperative skull image data, and then input the data into the 3D software for 3D reconstruction, complete the design of the artificial skull patch, and obtain the 3D data of the artificial skull patch.

[0040] 2. Raw material preparation

[0041] 2.1 Grind the autologous bone into powder at -15°C, and then pass refining and sieving to screen the autologous bone powder with a particle size of 100 μm;

[0042] 2.2 Prepare 0.2mol / L CaCl 2 Solution 20mL, according to the ratio of Ca / P molar ratio is 1.67, CaCl 2 The solution was slowly dropped into 24mL of 0.1mol / L H 3 PO 4 solution, and then use sodium hydroxide solution to adjust the pH value to 7-10 to form a gel of calcium hydroxyphosphate. After aging for 24 hours, wash it, then dry it in a drying oven at 105°C for 2 days, grind and sieve Finally, c...

Embodiment 2~7

[0050] Embodiment 2~7 and comparative example 1~6

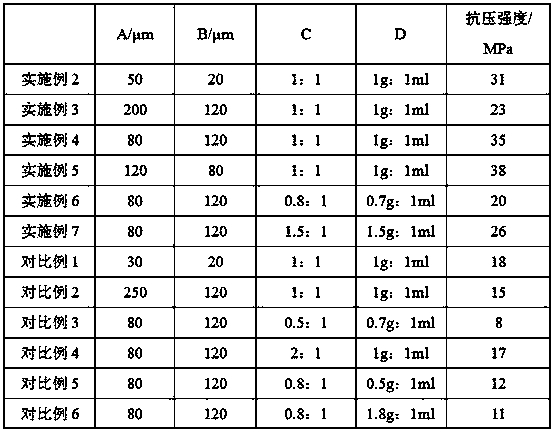

[0051] The preparation method steps and mechanical property testing methods of Examples 2-7 and Comparative Examples 1-6 are the same as Example 1, and the difference from Example 1 lies in the particle size (A) of autologous bone powder and the particle size (B) of calcium hydroxyphosphate. ), the mass ratio (C) of autologous bone powder and calcium hydroxyphosphate and the mass ratio (D) of the mass of the powder material to the volume of the dilute phosphoric acid (D), its specific parameters and mechanical properties are shown in Table 1:

[0052] Table 1

[0053]

[0054] control sample

[0055] The preparation method steps and mechanical property testing method of the control sample are the same as those in Example 1. The difference from Example 1 is that the control sample only uses calcium hydroxyphosphate with a particle size of 120 μm as the raw material of the 3D printing powder, without adding autologous bone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com