A kind of zwitterionic polymer for implantable sensor and preparation method thereof

A technology of zwitterions and polymers, which is applied in the direction of instruments, scientific instruments, analytical materials, etc., can solve the problems of increasing the production cycle and cost of sensors, reducing the concentration of analytes, etc., to improve detection sensitivity and accuracy, and strong anti-interference ability , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

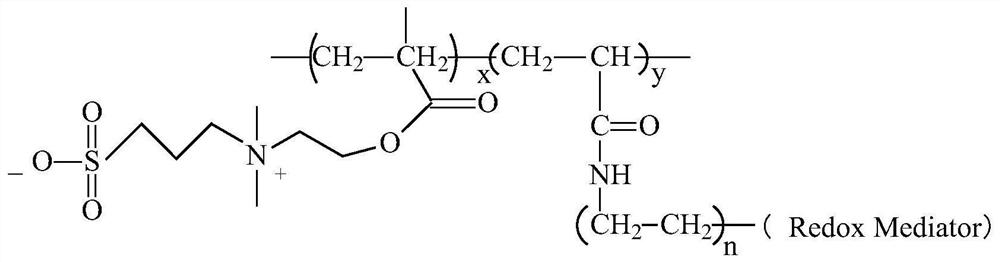

[0054] Example 1 SBMA and NH 2 -(CH 2 ) 6 (m-bim)Os(bpy) 2 2PF 6 Preparation of Zwitterionic Polymers by Polymerization

[0055] The thiobetaine methyl acrylate (SBMA) used in this example was purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., the osmium complex NH 2 -(CH 2 ) 6 (m-bim)Os(bpy) 2 2PF 6 For the synthesis of this research group, refer to the synthetic route in AnIntrinsic Self-Charging Biosupercapacitor Combined of a High-Potential Bioanode and a Low-Potential Biocathode, other reagents are known products, obtained by purchasing commercially available products.

[0056] (1) Copolymerization of acrylic acid (AA) and thiobetaine methyl acrylate (SBMA) monomer solution: Weigh 2.21g of AA and 0.04g of SBMA monomer in turn in a polymerization bottle filled with a certain amount of 0.3M NaCl solution, shake to make it Completely dissolved, nitrogen at room temperature. After adding 0.0018g of potassium persulfate and sodium bisulfite (mass ratio...

Embodiment 2

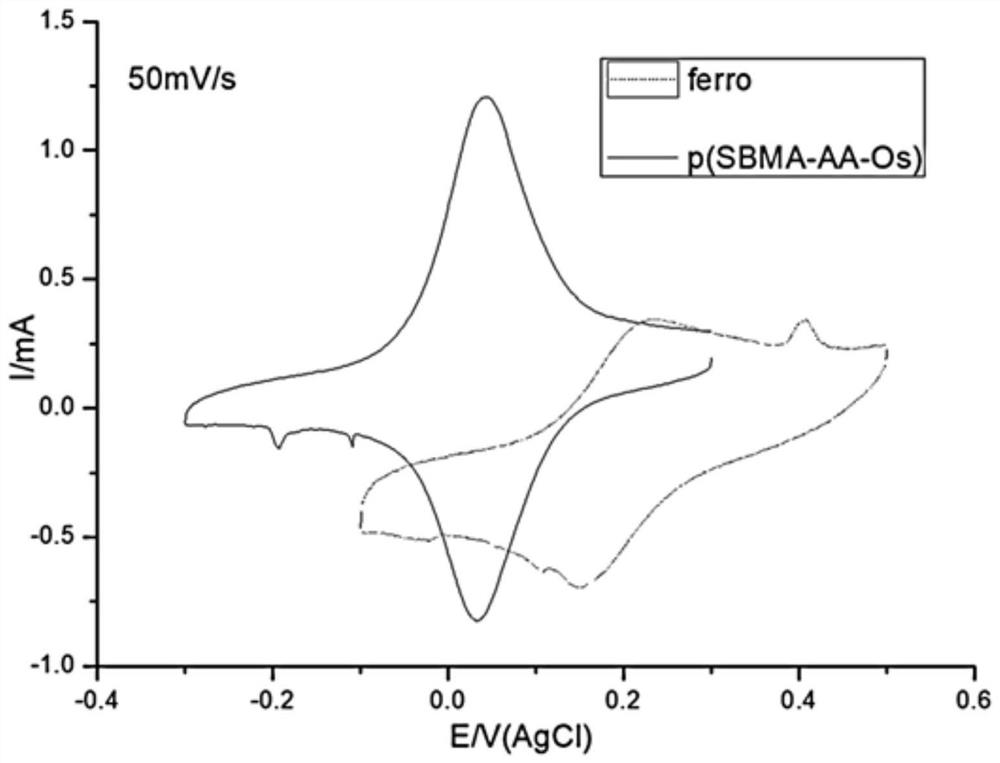

[0058] Example 2 Electrochemical characterization (CV) of p(SBMA-AA-Os) modified electrode

[0059] Using the p(SBMA-AA-Os) prepared in Example 1, prepare a pbs solution of 10 mg / ml p(SBMA-AA-Os), pipette 2 microliters of the solution to the surface of the glassy carbon electrode and dry it as a membrane-modified electrode , the electrochemical experiment was carried out on Chenhua CHI600 electrochemical workstation, 10mL electrolytic cell, three-electrode system: the membrane-modified glassy carbon electrode was used as the working electrode, Ag / AgCl was used as the reference electrode, the platinum wire electrode was used as the counter electrode, and the bottom solution was tested It is a phosphate buffer solution of pH 7.4, and the result of cyclic voltammetry is as follows figure 2 Shown, and compared with commonly used ferrocene-modified electrodes.

[0060] figure 2 The voltammogram of the zwitterionic polymer clearly shows specific peaks for the oxidation and subse...

Embodiment 3

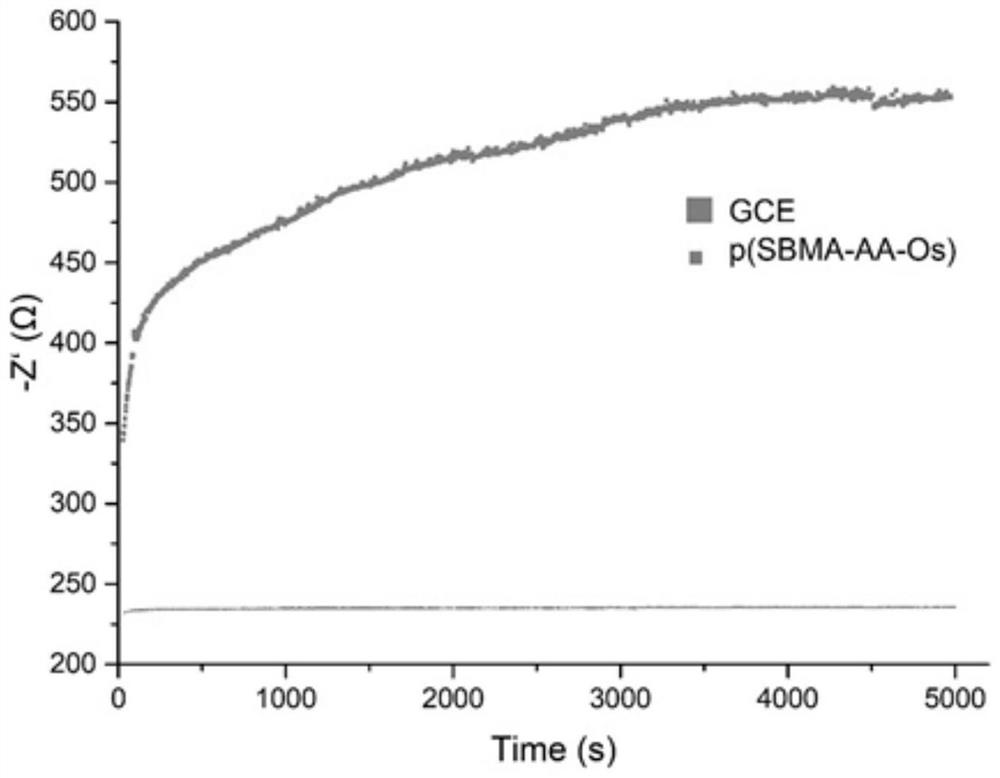

[0061] Example 3 Stability test of p(SBMA-AA-Os) modified electrode

[0062] Using the p(SBMA-AA-Os) modified electrode prepared in Example 2, in the in vitro experiment, the stability test of the electrode was performed using a newborn bovine whole serum solution stored at 37° C. to simulate the in vivo environment. Impedance (Z')-time (T) scanning was performed on the p(SBMA-AA-Os) modified electrode in neonatal bovine serum at 37°C, and the results were as follows image 3 shown, reflecting its performance in an in vitro environment. Depend on image 3It can be seen that the impedance of the p(SBMA-AA-Os) modified electrode only increased slightly in the first few minutes, and then quickly reached equilibrium and remained stable at 230Ω; after the glassy carbon bare electrode GCE was immersed in serum, its impedance increased rapidly, from 330Ω It quickly rose to 550Ω, and the overall impedance was nearly doubled, and it began to stabilize after about 1 hour. It can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com