Modified charcoal composite hydrogel as well as preparation method and application thereof

A technology of composite hydrogel and biochar, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problem of unsatisfactory adsorption effect of cadmium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

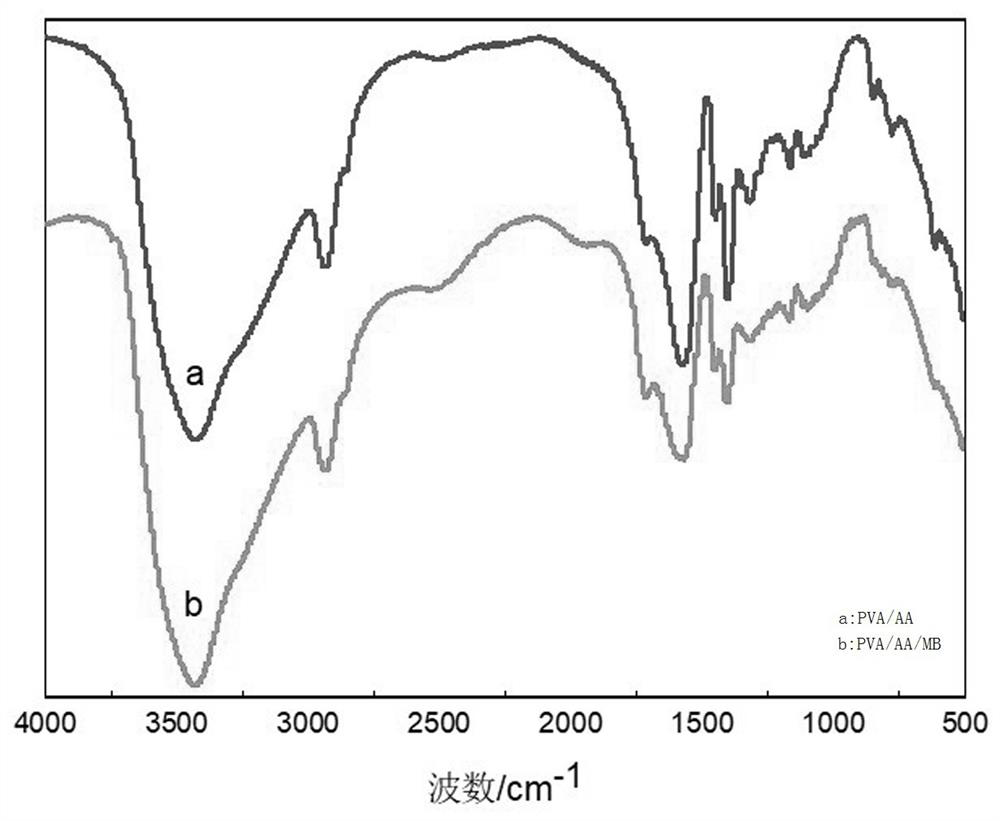

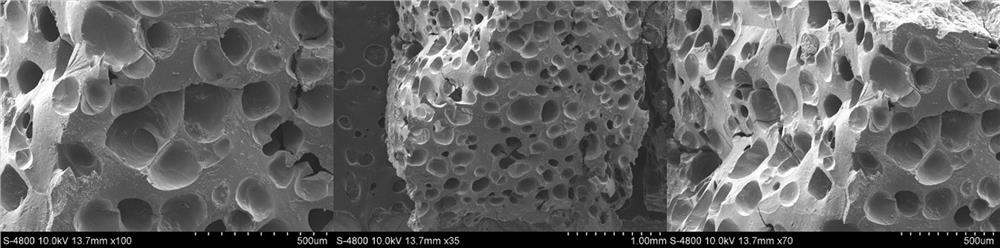

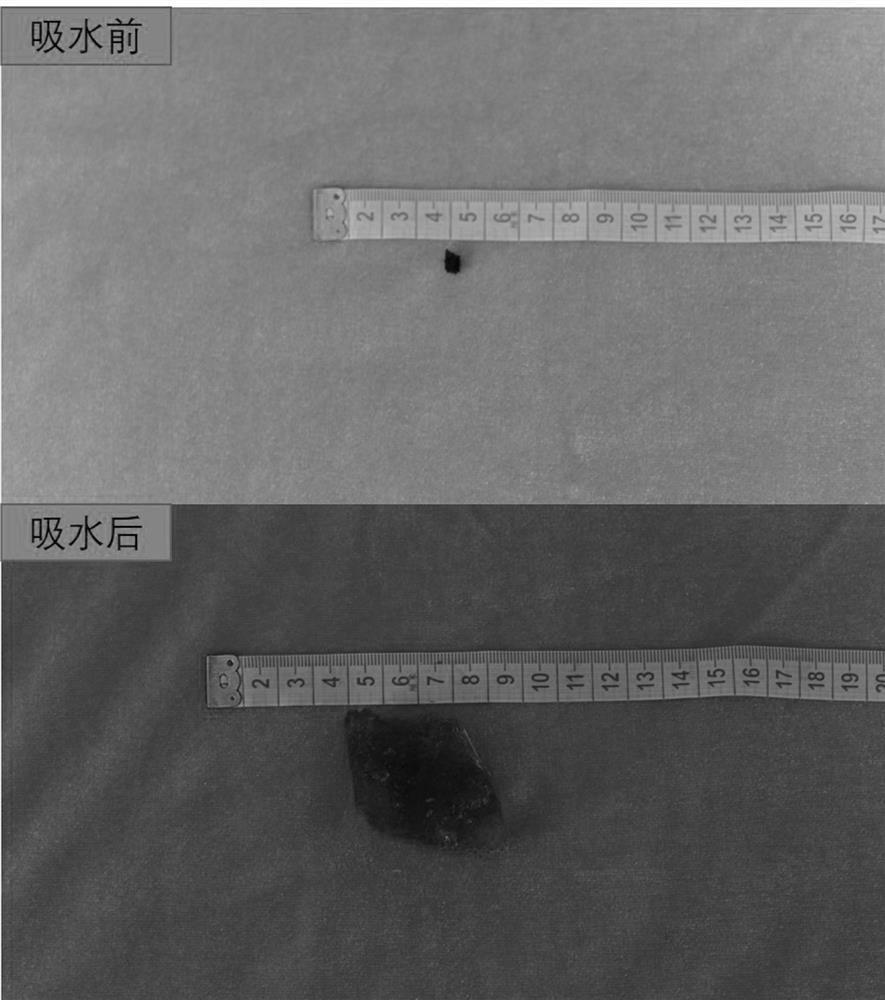

[0039] Embodiment 1: The modified biochar composite hydrogel provided in this example, the composite hydrogel includes nitric acid modified biochar, 5% polyvinyl alcohol aqueous solution, neutralized acrylic acid aqueous solution, ammonium persulfate and N, N'-methylenebisacrylamide, wherein modified biochar: 5% polyvinyl alcohol aqueous solution: neutralized acrylic acid aqueous solution = 1:20:80, the quality of ammonium persulfate is polyvinyl alcohol aqueous solution and neutralized acrylic acid The mass sum of the aqueous solution is 0.06%, and the mass of N,N'-methylenebisacrylamide is 0.04% of the mass sum of the polyvinyl alcohol aqueous solution and the neutralized acrylic acid aqueous solution.

[0040] Preparation:

[0041] The first step is to put peanut shell biochar into 12mol L -1 Heat and stir in the nitric acid solution at 60°C. The peanut shell biochar used was provided by Henan Huinong Soil Conservation Research and Development Co., Ltd., reacted for 6 hour...

Embodiment 2

[0045]Embodiment 2: The modified biochar composite hydrogel provided in this example, the composite hydrogel includes nitric acid modified biochar, 5% polyvinyl alcohol aqueous solution, neutralized acrylic acid aqueous solution, ammonium persulfate and N, N'-methylenebisacrylamide, wherein modified biochar: polyvinyl alcohol aqueous solution: neutralized acrylic acid aqueous solution=0.5:20:80, the quality of ammonium persulfate is the polyvinyl alcohol aqueous solution and the neutralized acrylic acid aqueous solution quality and 0.06% of N,N'-methylenebisacrylamide is 0.04% of the sum of polyvinyl alcohol aqueous solution and neutralized acrylic acid aqueous solution.

[0046] Preparation:

[0047] The first step is to put peanut shell biochar into 12mol L -1 Heat and stir in the nitric acid solution at 60°C, react for 6 hours, and rinse with distilled water repeatedly until neutral to remove excess oxidants and water-soluble compounds. Subsequently, the sample was dried ...

Embodiment 3

[0051] Embodiment 3: The modified biochar composite hydrogel provided in this embodiment, the composite hydrogel includes nitric acid modified biochar, 5% polyvinyl alcohol aqueous solution, neutralized acrylic acid aqueous solution, ammonium persulfate and N, N'-methylenebisacrylamide, wherein modified biochar: polyvinyl alcohol aqueous solution: neutralized acrylic acid aqueous solution=1.5:20:80, the quality of ammonium persulfate is the polyvinyl alcohol aqueous solution and the neutralized acrylic acid aqueous solution quality and 0.06% of N,N'-methylenebisacrylamide is 0.04% of the sum of polyvinyl alcohol aqueous solution and neutralized acrylic acid aqueous solution.

[0052] Preparation:

[0053] The first step is to put peanut shell biochar into 12mol L -1 Heat and stir in the nitric acid solution at 60°C, react for 6 hours, and rinse with distilled water repeatedly until neutral to remove excess oxidants and water-soluble compounds. Subsequently, the sample was dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com