Preparation method of montmorillonite/sol-gel composite coating

A technology of composite coating and montmorillonite, applied in the direction of coating, anti-corrosion coating, etc., can solve many problems such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

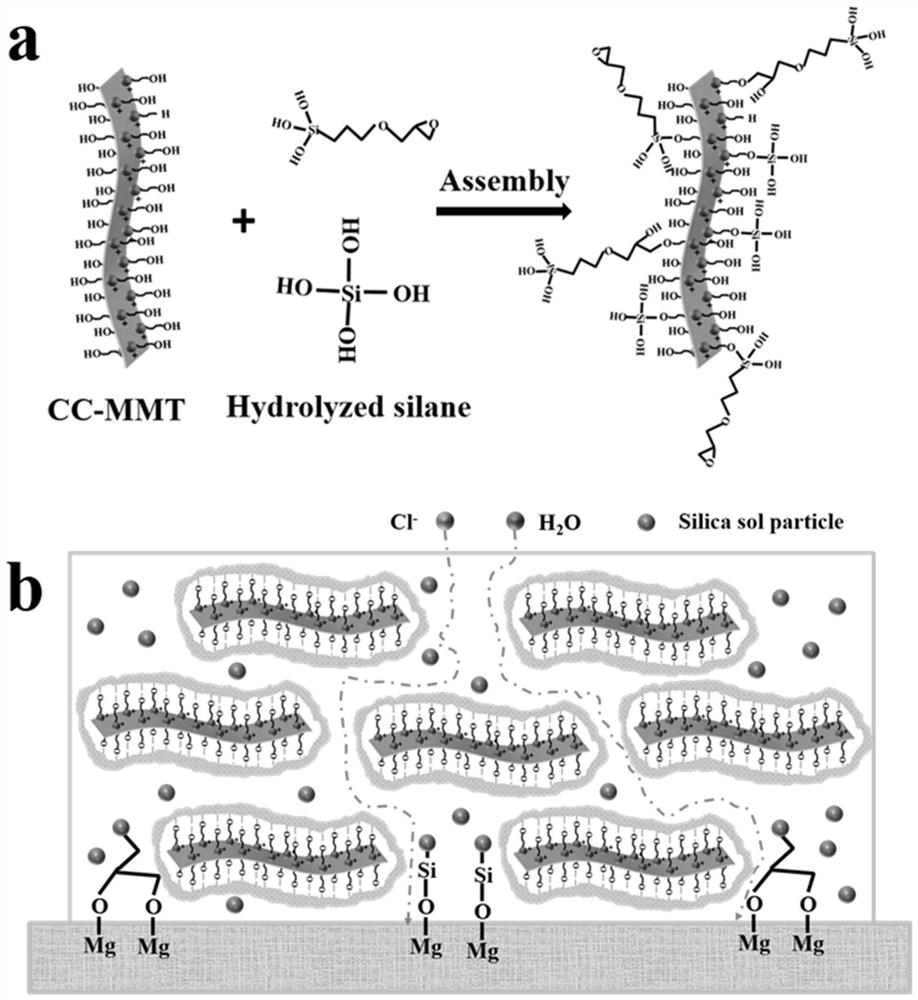

[0044] (1) Carry out intercalation modification to montmorillonite: CC and CTAB modification method are: add 10g original montmorillonite and 100ml deionized water to prepare slurry, process 6h under 250rpm in the ball mill; Add water to dilute to To a certain extent, treat it in a shearing machine at 5000rpm for 2 hours; put the above mixed solution in a water bath heating and stirring system, add an intercalation agent (CC or CTAB) twice the total amount of montmorillonite cation exchange, and treat it at 80°C 8h. Repeated centrifugal washing to remove excess intercalants and impurity ions, the final washed samples were dispersed in a small amount of absolute ethanol, dried at 60°C, and ground for later use. The obtained modified montmorillonites were respectively denoted as CC-MMT, CTA-MMT.

[0045] (2) Take 8.86g GPTMS, 2.6g TEOS and 23g EtOH, add 1 drop of HAc dropwise, stir magnetically at room temperature for 10min to make it fully mixed, and add 3.6g deionized water d...

Embodiment 2

[0055] (1) Carry out grafting modification to montmorillonite: get 1g of original montmorillonite and disperse in 50ml cyclohexane, dropwise add APTES twice the cation exchange amount of montmorillonite to it while stirring, stir at room temperature After 5 hours, the grafting reaction was fully carried out, and the obtained modified montmorillonite was denoted as AP-MMT.

[0056] (2) Prepare pure sol with step (2) of Example 1.

[0057] (3) Prepare the absolute ethanol dispersion of AP-MMT with step (3) of Example 1.

[0058] (4) Disperse the AP-MMT dispersion liquid into pure silica sol as in step (4) of Example 1, continue stirring for 24 hours, then adjust the temperature to 50° C. to evaporate part of the solvent to increase the viscosity of the system. Subsequently, the magnesium alloy sample was vertically immersed in the coating solution, heated in a water bath at 50°C for 1 hour, and then taken out. After the samples were left at room temperature for 12 hours, they ...

Embodiment 3

[0076] Compared with Example 1, most of them are the same, except that the hydrolysis process in step (2) is specifically: first pre-hydrolyze at room temperature for 20 minutes, and then continue to stir and hydrolyze at 60° C. for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com