Particle-reinforced refractory high-entropy composite material and preparation method thereof

A particle-reinforced, composite material technology, applied in the field of particle-reinforced refractory high-entropy composite materials and their preparation, can solve problems such as limiting wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] According to an embodiment of the present invention, a method for preparing a particle-reinforced refractory high-entropy composite material is also provided, comprising the following steps:

[0048] Step 1) Weigh the ingredients

[0049] The raw materials are: niobium powder (purity 99.9%, particle size<10μm), molybdenum powder (purity 99.9%, particle size<10μm), tantalum powder (purity 99.9%, particle size<10μm), tungsten powder (purity 99.9%, particle size diameter<10μm), rhenium powder (purity 99.9%, particle size<10μm), WC particles (purity 99.0%, particle size range 1-5μm).

[0050] The selected material is weighed according to the composition ratio.

[0051] Step 2) Alloying by ball milling

[0052] Put niobium powder, molybdenum powder, tantalum powder, tungsten powder, rhenium powder and WC particles into a tungsten carbide ball mill jar for ball mill alloying treatment to obtain mechanical alloyed powder. The ball milling process is filled with argon gas fo...

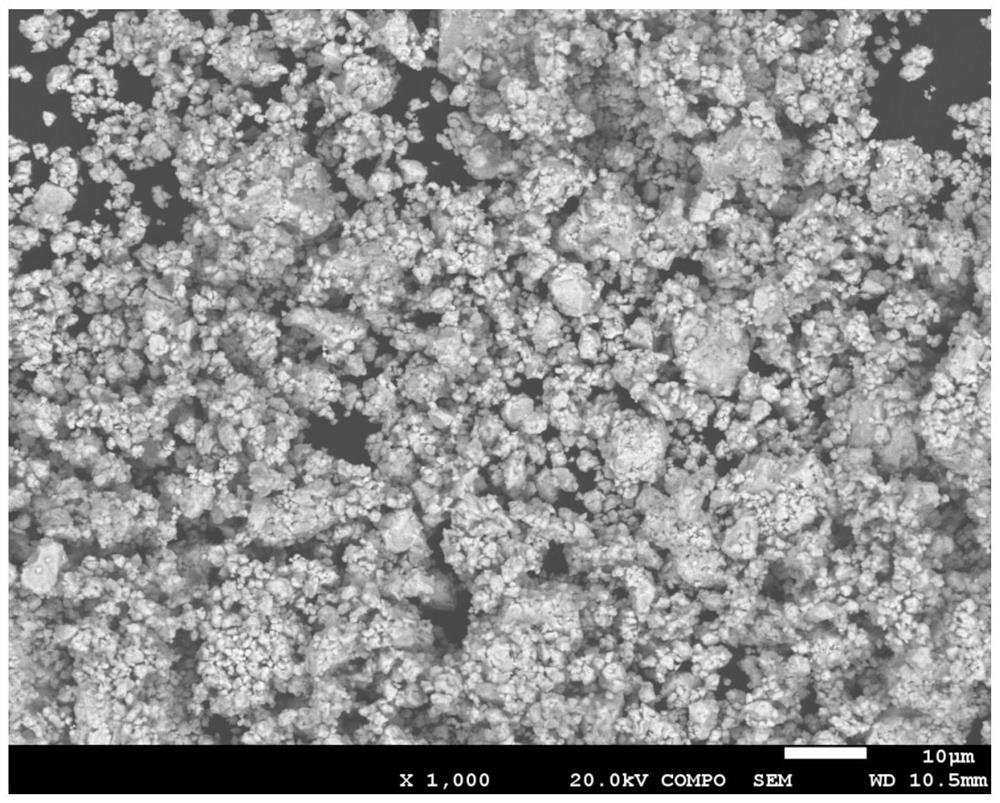

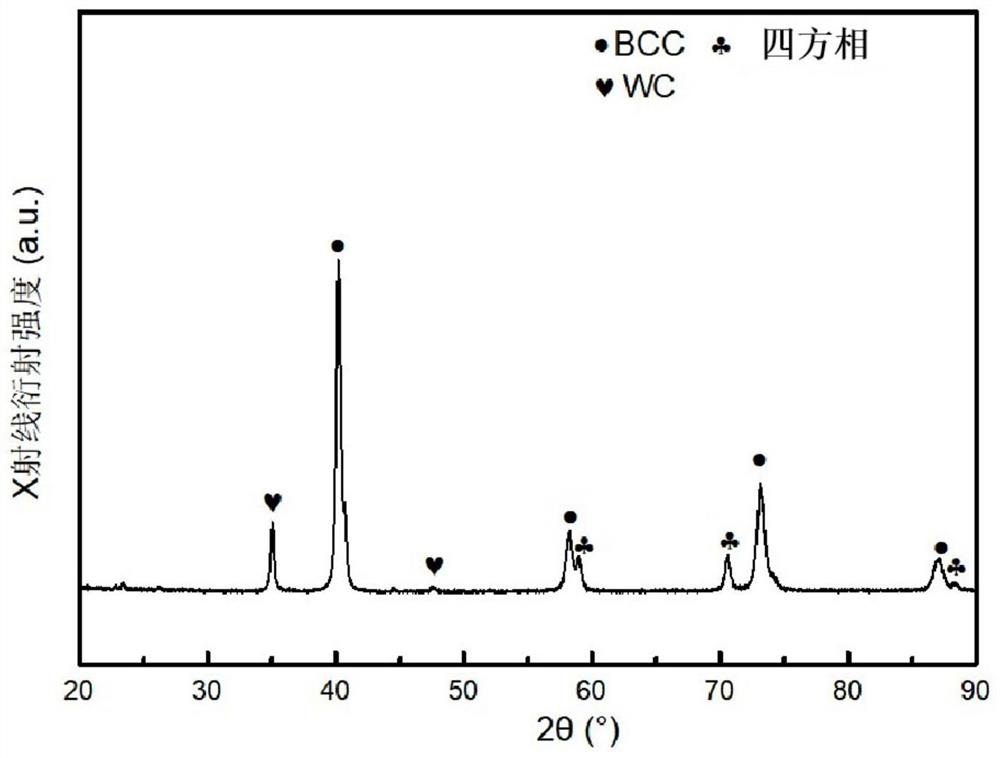

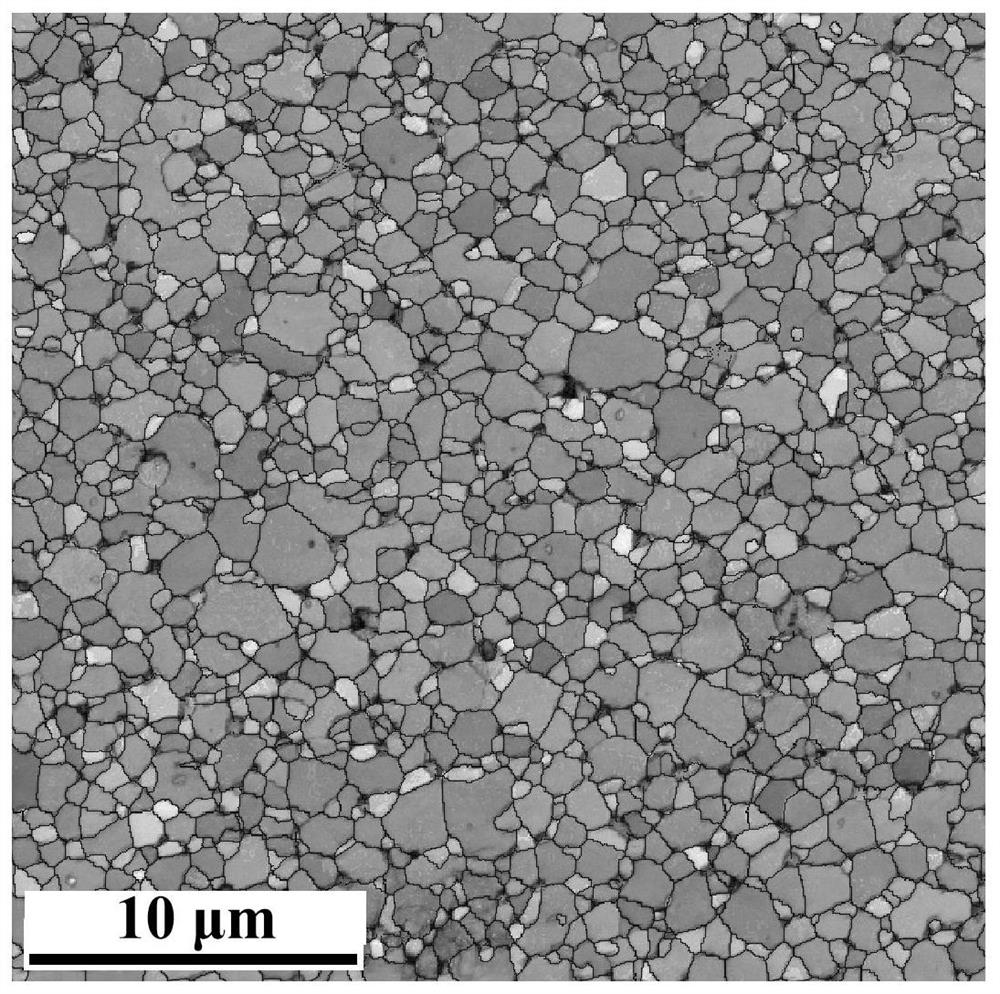

Embodiment 1

[0057] A particle-reinforced refractory high-entropy composite material, consisting of a refractory high-entropy alloy matrix and uniformly distributed WC particles, wherein the refractory high-entropy alloy matrix is composed of Nb, Mo, Ta, W, and Re elements in an equiatomic ratio , whose chemical formula is recorded as NbMoTaWRe; the amount of WC particles added is 1% of the mass of the refractory high-entropy alloy matrix in weight percentage.

[0058] The preparation method of the particle-reinforced refractory high-entropy composite material comprises the following steps:

[0059] Step 1) Weigh the ingredients, target NbMoTaWRe high entropy alloy 50g, WC particles 0.5g.

[0060] Substance materials used according to the design alloy are:

[0061]

[0062]

[0063] The selected materials were weighed according to the composition ratio to obtain the target particle-reinforced refractory high-entropy composite material NbMoTaWRe-1.0wt%WC.

[0064] Step 2) Alloying...

Embodiment 2

[0080] A particle-reinforced refractory high-entropy composite material, which consists of a refractory high-entropy alloy matrix and uniformly distributed WC particles, wherein the refractory high-entropy alloy matrix uses Nb, Mo, Ta, W, Re elements and according to non- Equivalent atomic ratio composition, its chemical formula is recorded as Nb 20 Mo 13 Ta 27 W 25 Re 15 ; The amount of WC particles added is 5% of the mass of the refractory high-entropy alloy matrix in terms of weight percentage.

[0081] The preparation method of the particle-reinforced refractory high-entropy composite material comprises the following steps:

[0082] Step 1) Weigh the ingredients, the target is Nb 20 Mo 13 Ta 27 W 25 Re 15 High entropy alloy 50g, WC particles 2.5g.

[0083] Substance materials used according to the design alloy are:

[0084]

[0085] The selected material is weighed according to the composition ratio to obtain the target particle reinforced refractory high-ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com