Phosphorus-doped bimetallic selenide electrocatalyst material with adjustable monometallic element electronic structure, and preparation method and application of phosphorus-doped bimetallic selenide electrocatalyst material

A technology of selenide electricity and metal elements, applied in the field of electrochemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

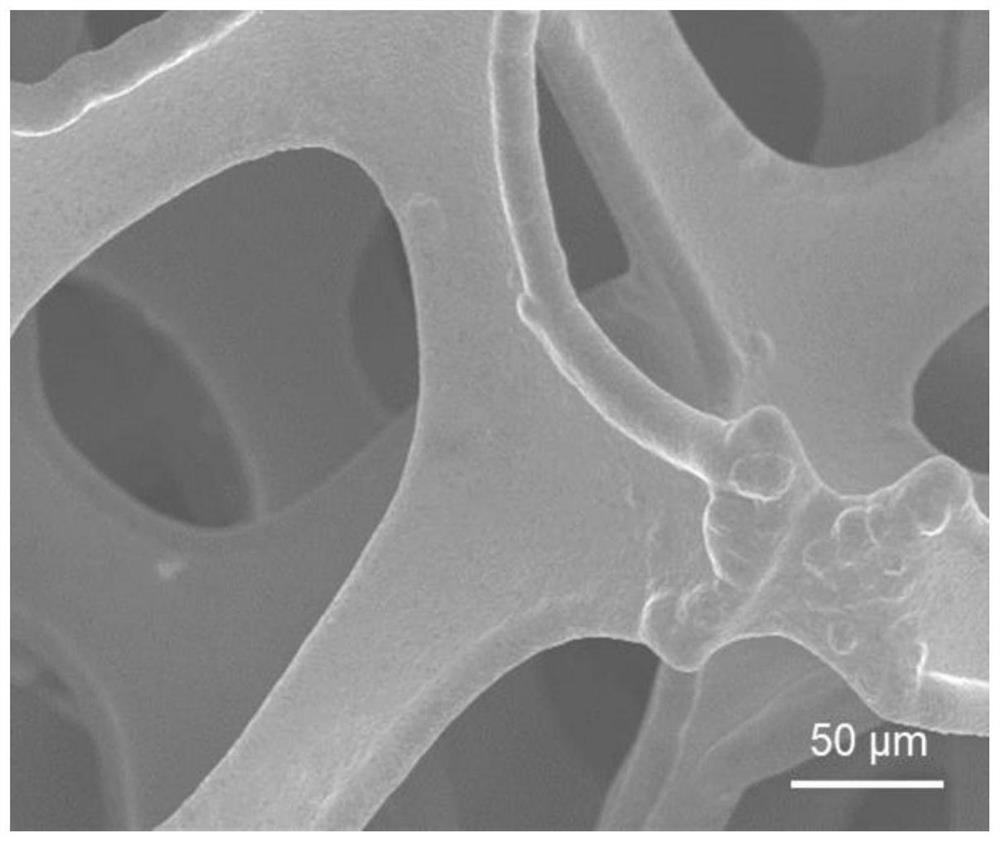

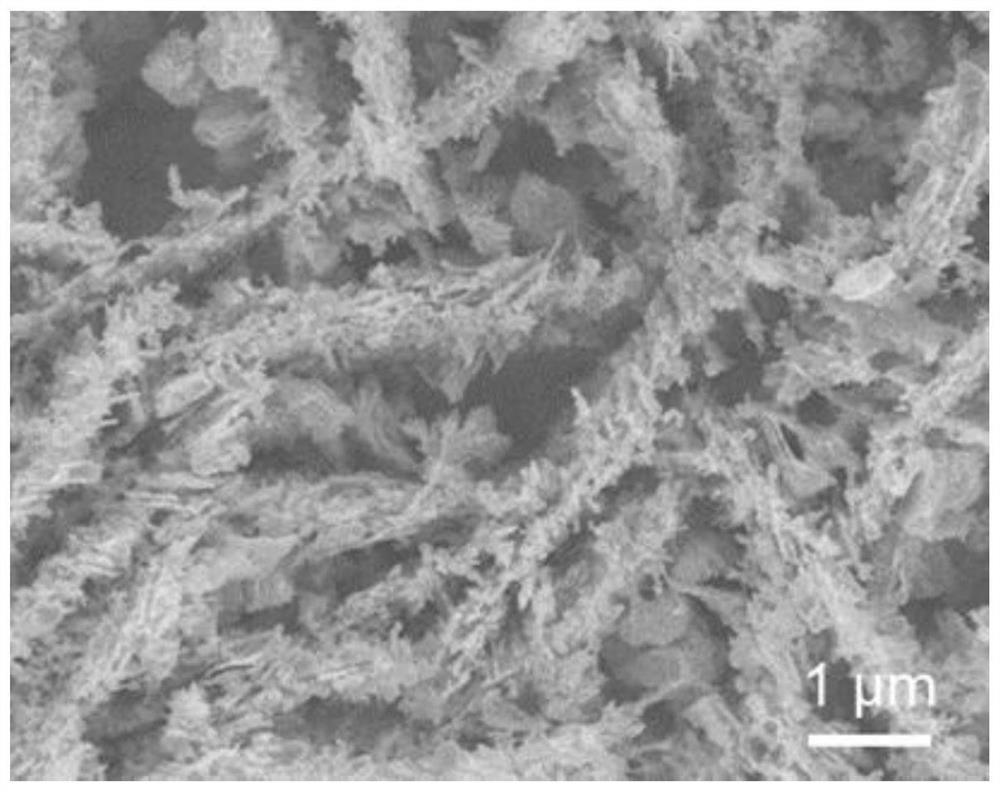

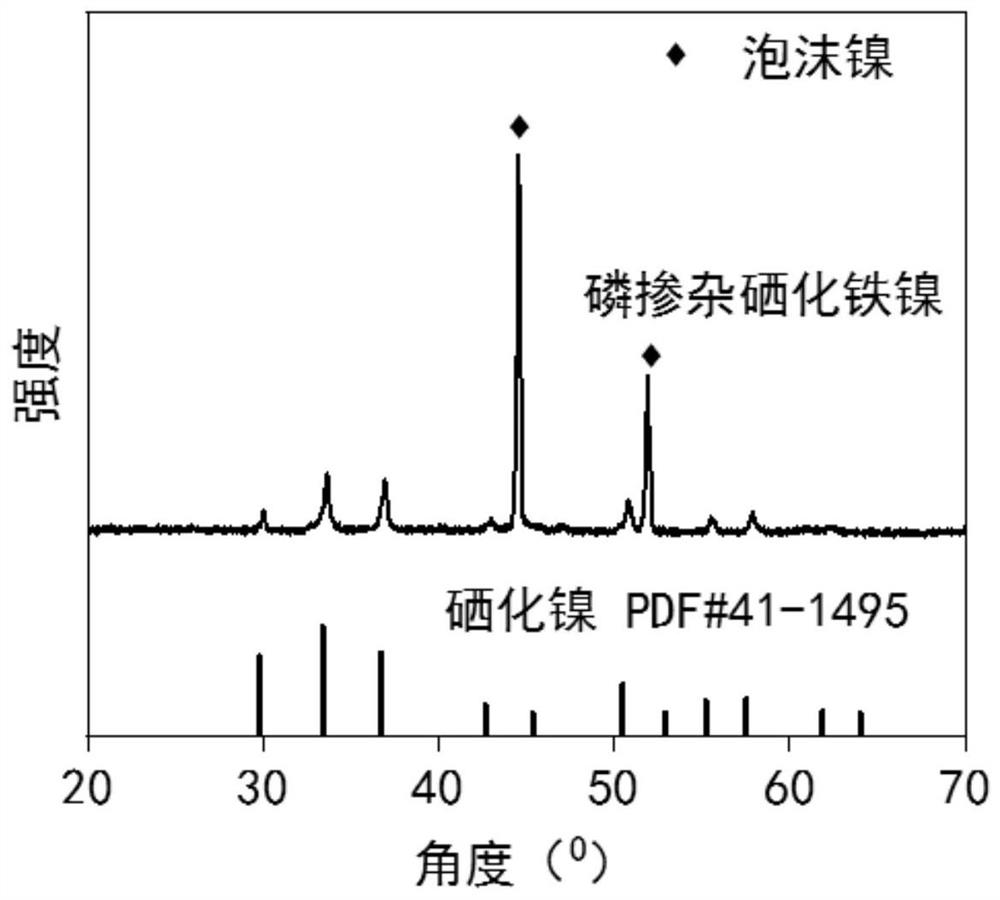

[0056] A preparation method of an iron-nickel selenide electrocatalyst material with adjustable electronic structure of a phosphorus-doped single metal element, comprising the following steps:

[0057] (1) Cut the selected nickel foam into 1*3cm 2 , using acetone, hydrochloric acid, deionized water, and ethanol to ultrasonically clean the cut foam nickel for 30 minutes respectively. After cleaning, put it into a vacuum drying oven and dry it under vacuum for 24 hours at 60° C. to obtain the pretreated foam nickel; The treated foamed nickel was placed in a reaction kettle containing 40mL nickel-iron precursor solution, and then hydrothermally reacted in an oven at 120°C for 16h; Dry at 60°C for 24 hours to obtain a foamed nickel precursor grown with nickel-iron hydrotalcite nanosheets.

[0058] (2) Put the foamed nickel precursor with nickel-iron hydrotalcite nanosheets into a reaction kettle equipped with 30mL 30mmol / L sodium selenium hydride solution, then hydrothermally rea...

Embodiment 2

[0070] A preparation method of an iron-nickel selenide electrocatalyst material with adjustable electronic structure of a phosphorus-doped single metal element, comprising the following steps:

[0071] (1) Cut the selected nickel foam into 1*3cm 2 , using acetone, hydrochloric acid, deionized water, and ethanol to ultrasonically clean the cut foam nickel for 30 minutes respectively. After cleaning, put it into a vacuum drying oven and dry it under vacuum for 24 hours at 60° C. to obtain the pretreated foam nickel; The treated foamed nickel was placed in a reaction kettle containing 40mL nickel-iron precursor solution, and then hydrothermally reacted in an oven at 120°C for 16h; Dry at 60°C for 24 hours to obtain a foamed nickel precursor grown with nickel-iron hydrotalcite nanosheets.

[0072] (2) Put the foamed nickel precursor with nickel-iron hydrotalcite nanosheets into a reaction kettle equipped with 30mL 30mmol / L sodium selenium hydride solution, then hydrothermally rea...

Embodiment 3

[0077] A preparation method of an iron-nickel selenide electrocatalyst material with adjustable electronic structure of a phosphorus-doped single metal element, comprising the following steps:

[0078] (1) Cut the selected nickel foam into 1*3cm 2 , using acetone, hydrochloric acid, deionized water, and ethanol to ultrasonically clean the cut foam nickel for 30 minutes respectively. After cleaning, put it into a vacuum drying oven and dry it under vacuum for 24 hours at 60° C. to obtain the pretreated foam nickel; The treated foamed nickel was placed in a reaction kettle containing 40mL nickel-iron precursor solution, and then hydrothermally reacted in an oven at 120°C for 16h; Dry at 60°C for 24 hours to obtain a foamed nickel precursor grown with nickel-iron hydrotalcite nanosheets.

[0079] (2) Put the foamed nickel precursor with nickel-iron hydrotalcite nanosheets into a reaction kettle equipped with 30mL 30mmol / L sodium selenium hydride solution, then hydrothermally rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Horizontal length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com