Flame-retardant cosmetic brush wire and preparation method thereof

A cosmetic brush and flame retardant technology, which is applied in the manufacture of fire-retardant and flame-retardant filament, rayon, and conductive/antistatic filament, etc. Wire performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

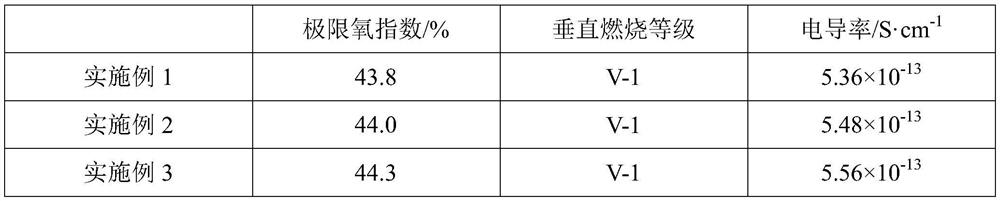

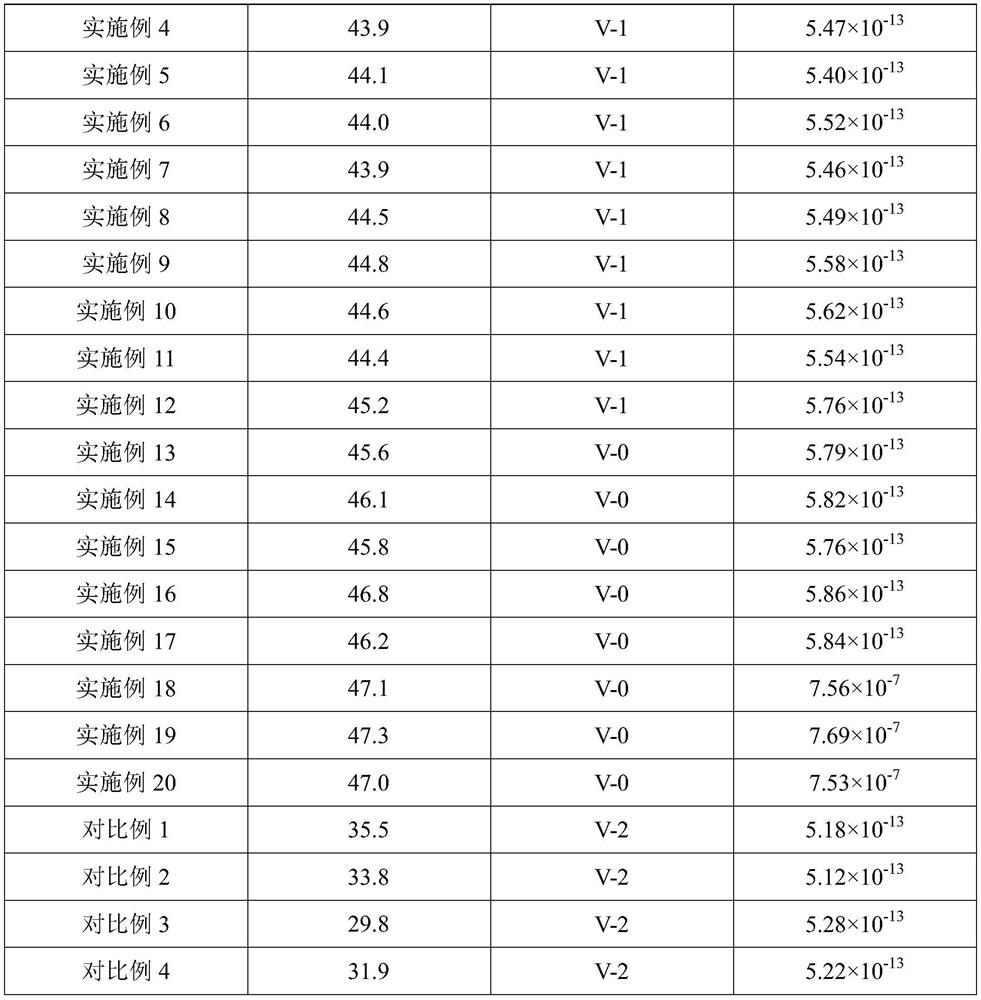

Examples

preparation example Construction

[0035] Preparation Examples of Raw Materials and Intermediates

[0036] raw material

[0037] Epoxy resin, using E44 epoxy resin;

[0038] Acrylic acid, industrial grade, purchased from Shandong Chuangying Chemical Co., Ltd., item number 01;

[0039] Sodium-based bentonite and calcium-based bentonite were purchased from Shijiazhuang Huabang Mineral Products Co., Ltd.;

[0040] The plasticizer is diisopropyl adipate, purchased from Candice Chemical (Hubei) Co., Ltd., article number kds15641262;

[0041] The curing agent is 4,4-diaminodiphenylmethane (DDM), purchased from Shanghai Puzhen Biotechnology Co., Ltd.;

[0042] The cross-linking agent was benzoyl peroxide, which was purchased from Shanghai Macklin Biochemical Technology Co., Ltd.

[0043] SO 4 2- -Fe 2 o 3 Solid acid, SO 4 2— -ZrO 2 Solid acid, SO 4 2— -TiO 2 Solid acid, purchased from Jiangyin Nanda Synthetic Chemical Company;

[0044] Ammonium polyphosphate (APP), purchased from Shandong Kepler Biotech...

preparation example 1

[0049]The preparation method of modified ammonium polyphosphate is:

[0050] 1) 500g ammonium polyphosphate is dissolved in ethanol to form a suspension;

[0051] 2) Dissolve 200g of anhydrous aluminum chloride powder in 1L of deionized water to prepare solution A;

[0052] 3) Add solution A to the ammonium polyphosphate suspension and stir for 40 minutes to prepare solution B;

[0053] 4) Add 0.5L of ammonia water to solution B, stir until the pH value of the solution is 8, then let it stand in a constant temperature water bath at 60°C for 2 hours, and finally filter, wash, and dry the precipitated product and pulverize it into powder. ammonium polyphosphate.

preparation example 2

[0055] The preparation method of flame retardant is:

[0056] 2kgSO 4 2- -Fe 2 o 3 Solid acid, 40kg of ammonium polyphosphate, and 10kg of silicon dioxide were uniformly mixed to obtain a flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com