Method for preparing metal homogeneous and hybrid ultramicro electrode by using carbon template and electroplating method

An ultra-micro electrode and carbon electrode technology, applied in the field of analytical chemistry, can solve the problems of poor preparation repeatability, single signal, and inability to mass-produce, and achieve the effect of high success rate and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, the preparation of silanized carbon deposition template

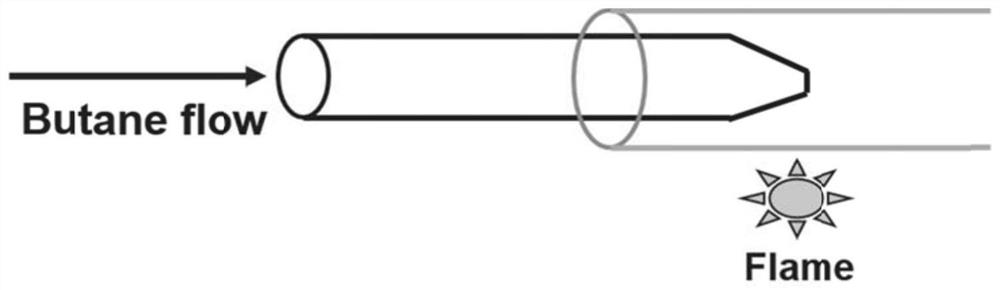

[0043] Draw the quartz double tube into an empty tube of the required size, fix it at the end of the butane pipeline, make the pipeline full of butane gas (purity is 99.9%, butane gas pressure is 0.03MP), and then put it Inserted into the quartz protective sleeve (quartz single tube) on the opposite side, the inserted micro-nano tip accounts for about one-twentieth of the entire micro-nano tube. At this time, nitrogen does not need to be introduced into the protective sleeve, and the outer flame of an alcohol lamp or an alcohol blowtorch is used for heating for 60s to 200s. The specific heating time depends on the diameter of the tube, that is, the tip required for the first step is not completely blocked. The living ultra-fine carbon electrode is called a carbon template, and the subsequent electrodeposition experiments are all completed on this template.

[0044]In order to prevent the irregular ...

Embodiment 2

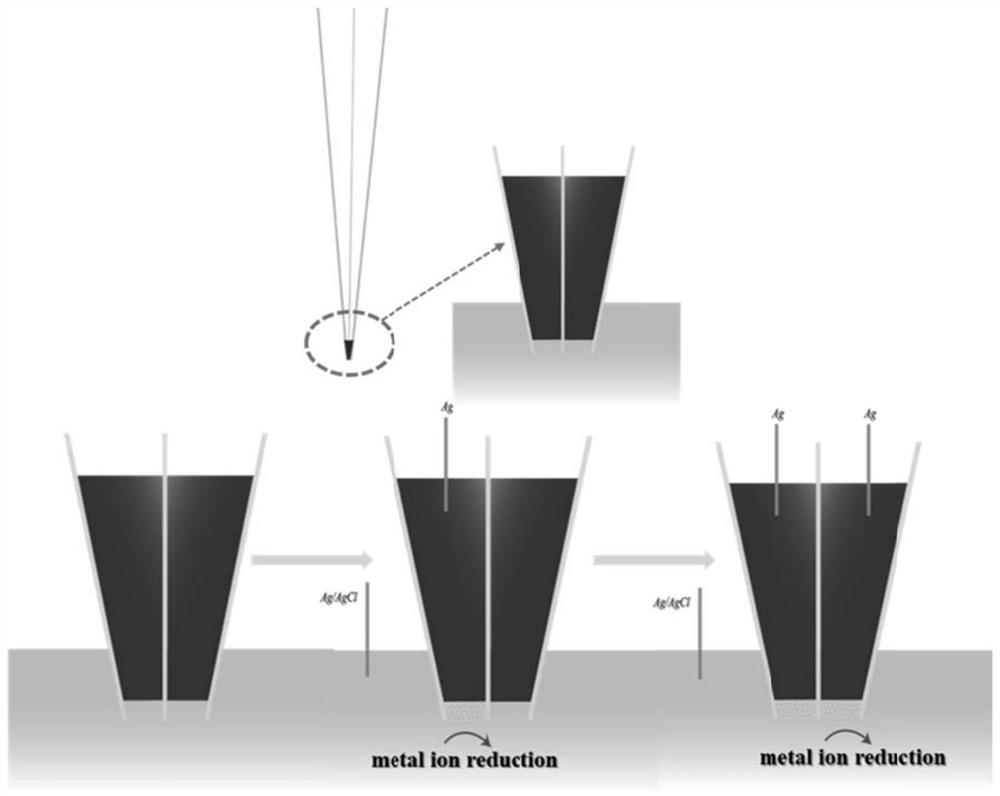

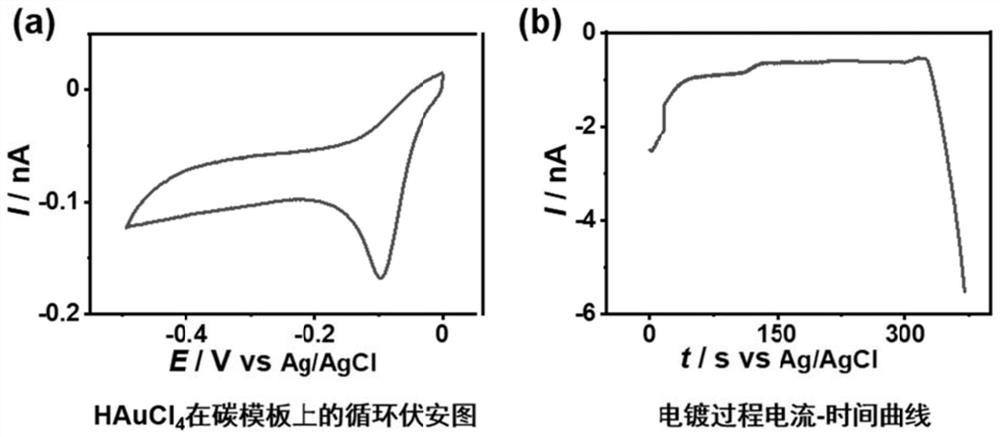

[0046] The above silanized carbon template was inserted into the potassium chloride solution containing 1mM chloroauric acid, and AuCl was determined by cyclic voltammetry. 4 - The reduction potential (such as image 3 a), the results show that AuCl 4 - When it is lower than 0V, it starts to be reduced to simple gold. Such as image 3 As shown in b, in the constant potential plating process, first AuCl 4 - It is reduced to gold on the carbon layer, and as the gold gradually covers the carbon layer, the AuCl diffused to the surface of the gold 4 - It began to grow gradually on the gold simple substance, and after a period of time, the gold nanoparticles filled the entire channel; continued electrodeposition, and the current increased rapidly as the nanoparticles grew outward, indicating that the gold nanoparticles just completely filled the channel. on both sides of the double tube figure 2 As shown in the electroplating process, after the electroplating is finished, ...

Embodiment 3

[0050] Draw the quartz double tube into an empty tube of the required size, fix it at the end of the butane pipeline, fill the pipeline with butane gas, and then insert it into the quartz protective sleeve on the opposite side, at this time There is no need to feed nitrogen gas into the protective sleeve, and heat it with an alcohol lamp or the outer flame of an alcohol blowtorch for 60s to 200s. The specific heating time depends on the size of the tube diameter, that is, to prepare the blank carbon template at the tip required for the first step and Silanize the outer wall.

[0051] The above preparation process is as figure 1 shown.

[0052] Insert the electrode prepared above into the potassium chloride solution containing 2mM chloroplatinic acid, and determine the electroplating potential according to its reduction potential in the solution, at which potential, the chloroplatinate ions in the solution will be reduced to platinum nanoparticles Inside the quartz tube, stop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com