Preparation method of high-entropy oxide with good infrared radiation performance

A technology of infrared radiation and oxide, applied in the field of infrared radiation materials, can solve the problems of high raw material cost, long cycle, uncontrollable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh CuO11.933g (0.15mol), MnO 2 13.041g (0.15mol), ZnO12.207g (0.15mol), Fe 2 o 3 11.977g (0.075mol) powder; according to the mass ratio of ball: material: water 4:1:3, pour the ball mill beads, raw materials and ultrapure water into the ball mill jar; and place the ball mill jar on the ball mill station for 1 hour Ball milling at a speed of 450r / min, followed by a pause of 10 minutes, as a ball milling cycle, after 10 minutes, ball milling for 1 hour at a speed of 450r / min, and a total of 7 hours of ball milling to obtain a mixed powder; then the mixed powder obtained after ball milling was dried , Put it in a box-type resistance furnace after grinding, heat up to 650°C in air atmosphere (heating rate is 14°C / min), calcined for 7 hours, and then air quenched and cooled to room temperature to obtain single-phase (Cu, Mn, Zn, Fe) 3 o 4 High entropy oxide powder.

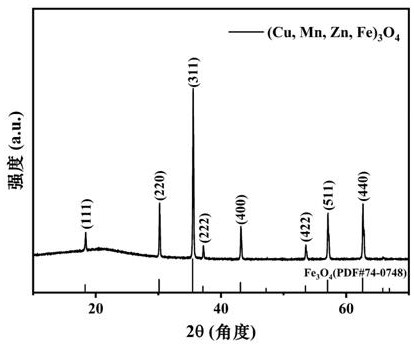

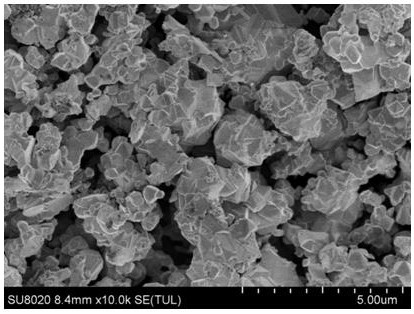

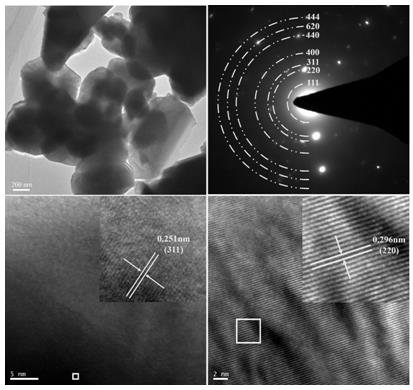

[0031] figure 1 For the as-prepared (Cu, Mn, Zn, Fe) 3 o 4 XRD patterns of high-entropy oxides, wh...

Embodiment 2

[0037] Weigh CuO11.933g (0.15mol), MgO6.045g (0.15mol), Cr 2 o 3 11.399g (0.075mol), TiO 2 11.985g (0.15mol) powder; according to the mass ratio of ball: material: water 2:1:3, pour the ball mill beads, raw materials and ultrapure water into the ball mill jar; and place the ball mill jar on the ball mill station for 1 hour Ball milling at a speed of 300r / min, followed by a pause of 10min, as a ball milling cycle, after 10min, ball milling for 1 hour at a speed of 300r / min, and a total of 5 hours of ball milling to obtain a mixed powder; then the mixed powder obtained after ball milling was dried, After grinding, place it in a box-type resistance furnace, heat up to 500°C in air atmosphere (heating rate is 10°C / min), calcinate for 1 hour, and then cool to room temperature with the furnace to obtain single-phase (Cu, Mg, Cr, Ti ) 3 o 4 High entropy oxides.

[0038] Figure 6 For the prepared (Cu, Mg, Cr,Ti) 3 o 4 XRD patterns of high-entropy oxides, which are consistent ...

Embodiment 3

[0041] Weigh CuO11.933g (0.15 mol), Cr 2 o 3 11.399g (0.075mol), Co 3 o 4 12.040g (0.05mol), TiO 2 11.985g (0.15 mol) powder; according to the mass ratio of ball: material: water 4:1:3, pour the ball mill beads, raw materials and ultrapure water into the ball mill jar; Ball milling for 1 hour at a speed of 400r / min, followed by a pause of 10min, as a ball milling cycle, after 10min, ball milling for 1 hour at a speed of 400r / min, and a total of 9 hours of ball milling to obtain a mixed powder; then the mixed powder after ball milling was dried , Put it in a box-type resistance furnace after grinding, heat up to 970°C in air atmosphere (heating rate is 11°C / min), calcinate for 2 hours, and then cool to room temperature with the furnace to obtain single-phase (Cu, Cr, Co, Ti ) 3 o 4 High entropy oxides.

[0042] Figure 7 As prepared (Cu, Cr, Co, Ti) 3 o 4 XRD patterns of high-entropy oxides, which are consistent with Fe with spinel structure in the ICDD database 3 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com