Special adhesive for optical film

A technology of optical films and modifiers, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

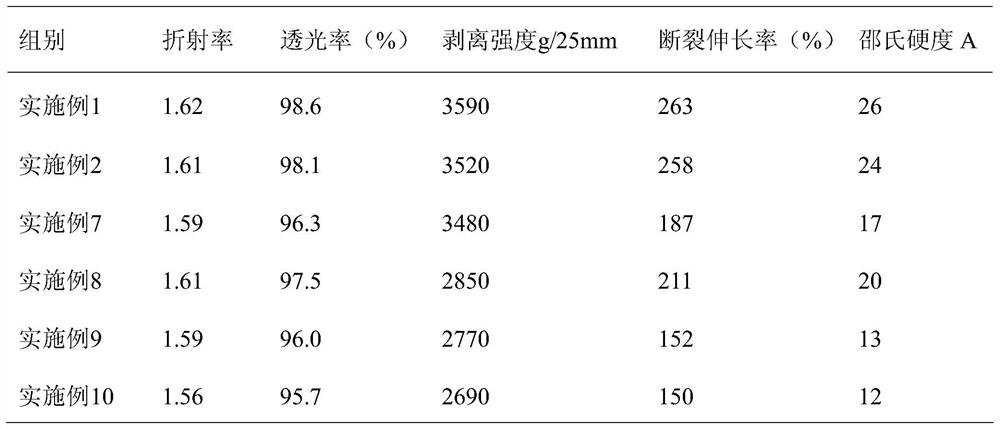

Examples

Embodiment 1

[0042] A special adhesive for optical films, prepared from components comprising the following parts by weight:

[0043] 46 parts of o-phenylphenoxyethyl acrylate,

[0044] 32 parts of ethoxylated bisphenol A dimethacrylate,

[0045] Initiator 184 2 parts,

[0046] 4 parts of silicone additives,

[0047] 6 parts of tetrahydrofurfuryl alcohol acrylate,

[0048] 7 parts of trimethylol cyclohexyl acrylate,

[0049] 8 parts of bisphenol fluorene acrylate,

[0050] Modifier 3 parts.

[0051] The preparation method of described organosilicon additive comprises the steps:

[0052] S1. Mix lithium hydroxide and octamethylcyclotetrasiloxane, react at 155°C for 1.5h under the protection of nitrogen, and obtain auxiliary agent I after cooling; the lithium hydroxide and octamethylcyclotetrasiloxane The mass ratio of alkanes is 1:220.

[0053] S2. Add octamethylcyclotetrasiloxane, additive I, hexamethylcyclotrisiloxane, and trimethylbenzyl ammonium chloride to the high-shear emulsi...

Embodiment 2

[0060]A special adhesive for optical films, prepared from components comprising the following parts by weight:

[0061] 52 parts of o-phenylphenoxyethyl acrylate,

[0062] 4 parts ethoxylated bisphenol A dimethacrylate,

[0063] Initiator 1173 3 parts,

[0064] 5 parts of silicone additives,

[0065] 7 parts of tetrahydrofurfuryl alcohol acrylate,

[0066] 7 parts of trimethylol cyclohexyl acrylate,

[0067] 7 parts of bisphenol fluorene acrylate,

[0068] Modifier 4 parts.

[0069] The preparation method of described organosilicon additive comprises the steps:

[0070] S1. Mix lithium hydroxide and octamethylcyclotetrasiloxane, react at 158°C under nitrogen protection for 1.5h, and obtain auxiliary agent I after cooling; the lithium hydroxide and octamethylcyclotetrasiloxane The mass ratio of alkanes is 1:240.

[0071] S2. Add octamethylcyclotetrasiloxane, additive I, hexamethylcyclotrisiloxane, and trimethylbenzyl ammonium chloride to the high-shear emulsifier in seq...

Embodiment 3

[0078] A special adhesive for optical films, prepared from components comprising the following parts by weight:

[0079] 41 parts o-phenylphenoxyethyl acrylate,

[0080] 30 parts of ethoxylated bisphenol A dimethacrylate,

[0081] Initiator 184 2 parts,

[0082] 3 parts of silicone additives,

[0083] 6 parts of tetrahydrofurfuryl alcohol acrylate,

[0084] 6 parts of trimethylol cyclohexyl acrylate,

[0085] 5 parts of bisphenol fluorene acrylate,

[0086] Modifier 2 parts.

[0087] The preparation method of described organosilicon additive comprises the steps:

[0088] S1. Mix lithium hydroxide and octamethylcyclotetrasiloxane, react at 150°C for 2 hours under nitrogen protection, and obtain auxiliary agent I after cooling; the lithium hydroxide and octamethylcyclotetrasiloxane The mass ratio is 1:210.

[0089] S2. Add octamethylcyclotetrasiloxane, additive I, hexamethylcyclotrisiloxane, and trimethylbenzyl ammonium chloride to the high-shear emulsifier in sequence, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com