Composite disinfectant and preparation method thereof

The technology of a disinfectant and a compound is applied in the field of compound disinfectant and its preparation, and can solve the problems of high power consumption of equipment, poor treatment effect of ozone on algae and red nematodes, and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

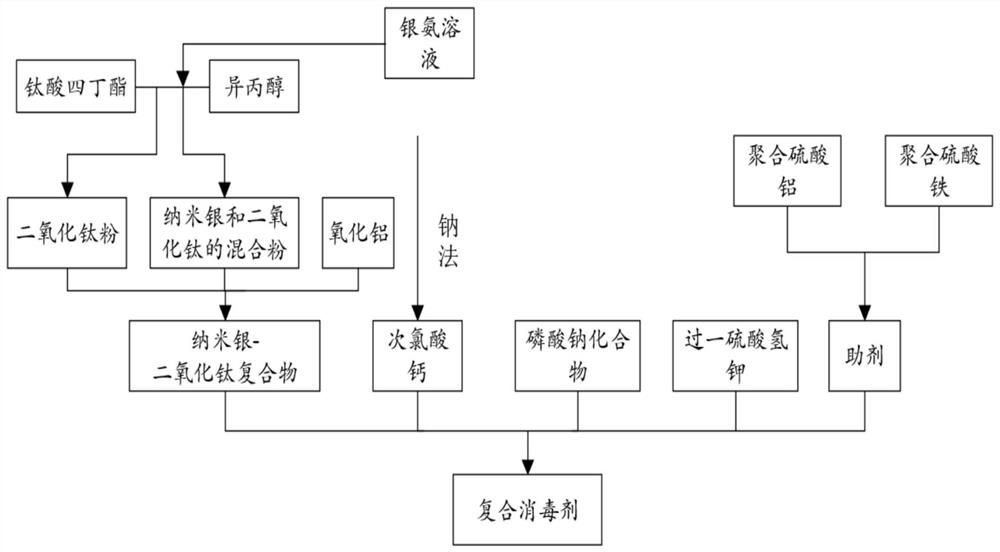

[0055] According to another typical embodiment of the present invention, a kind of preparation method of compound disinfectant is provided, and described method comprises:

[0056] After mixing calcium hypochlorite, sodium phosphate compound, and potassium hydrogen persulfate evenly, add nano-silver-titanium dioxide compound and stir, and add additives while stirring until all components are evenly mixed, and the compound disinfection agent.

[0057] First mix the calcium hypochlorite, sodium phosphate compound, and potassium monopersulfate evenly, and its effect is that when the powders of calcium hypochlorite, potassium monopersulfate and sodium phosphate compound are mixed evenly, the three are not yet in the In the aqueous solution, the mutual reaction cannot start, and then add the nano-silver-titanium dioxide composite, because the nano-silver-titanium dioxide composite has a small particle size, it can be mixed evenly in the above-mentioned three uniformly mixed powders...

Embodiment 1

[0061] Such as figure 1 Shown, described composite disinfectant counts in parts by weight: the calcium hypochlorite of 60 parts, the sodium hexametaphosphate of 5 parts, the potassium hydrogen persulfate of 7 parts, the nanometer silver-titanium dioxide composite of 10 parts , 8 parts of additives; the sodium method calcium hypochlorite is purchased from Tianjin Xinxin Chemical Factory, and the available chlorine content is 65%; the nano silver-titanium dioxide composite includes 8 parts by weight of silver, 70 parts of titanium dioxide, 12 parts of aluminum oxide; the particle size of the silver is 13nm, the particle size of the titanium dioxide is 15nm, and the particle size of the aluminum oxide is 10nm; the auxiliary agent includes parts by weight The number is 22 parts of polyaluminum sulfate and 3 parts of polyferric sulfate.

Embodiment 2

[0063] Described composite disinfectant is counted as in parts by weight: 50 parts of calcium hypochlorite, 2 parts of sodium hexametaphosphate, 5 parts of potassium monopersulfate, 8 parts of nanometer silver-titanium dioxide composite, 2 parts auxiliary agent; the sodium method calcium hypochlorite is purchased from Tianjin Xinxin Chemical Factory, and the available chlorine content is 70%; the nano-silver-titanium dioxide composite includes 2 parts by weight of silver, 60 parts of Titanium dioxide, 10 parts of aluminum oxide; the particle size of the silver is 10nm, the particle size of the titanium dioxide is 5nm, and the particle size of the aluminum oxide is 5nm; the auxiliary agent includes 20 parts by weight Parts of polyaluminum sulfate, 2 parts of polyferric sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com