Method for preparing ceramic material through ultraviolet light beam synchronous curing assisted direct writing 3D printing

A technology of ceramic materials and ultraviolet light beams, applied in ceramic molding machines, manufacturing tools, additive processing, etc., can solve problems such as uneven curing, cumulative defects, and overexposure of light-assisted direct writing molding processes, and achieve easy promotion, Broad application prospects and low curing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

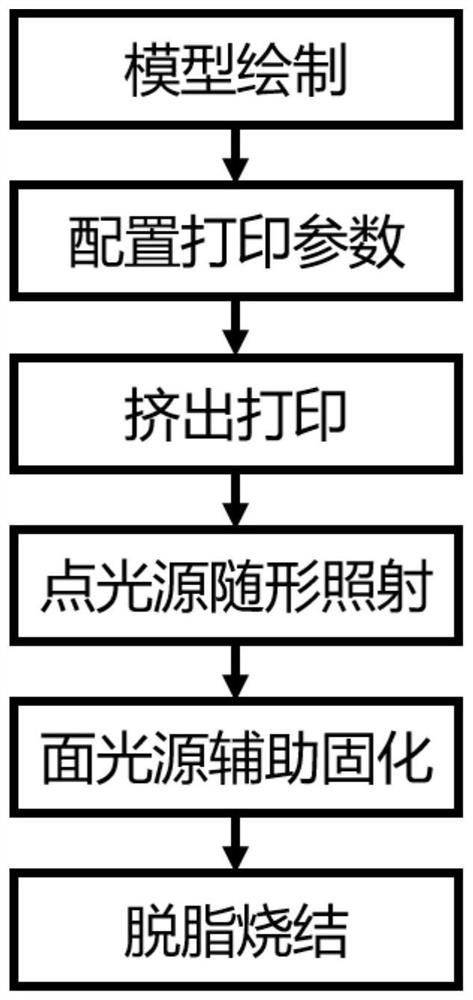

[0029] In this embodiment, the method for preparing ceramic materials by direct writing 3D printing assisted by ultraviolet beam synchronous curing is as follows:

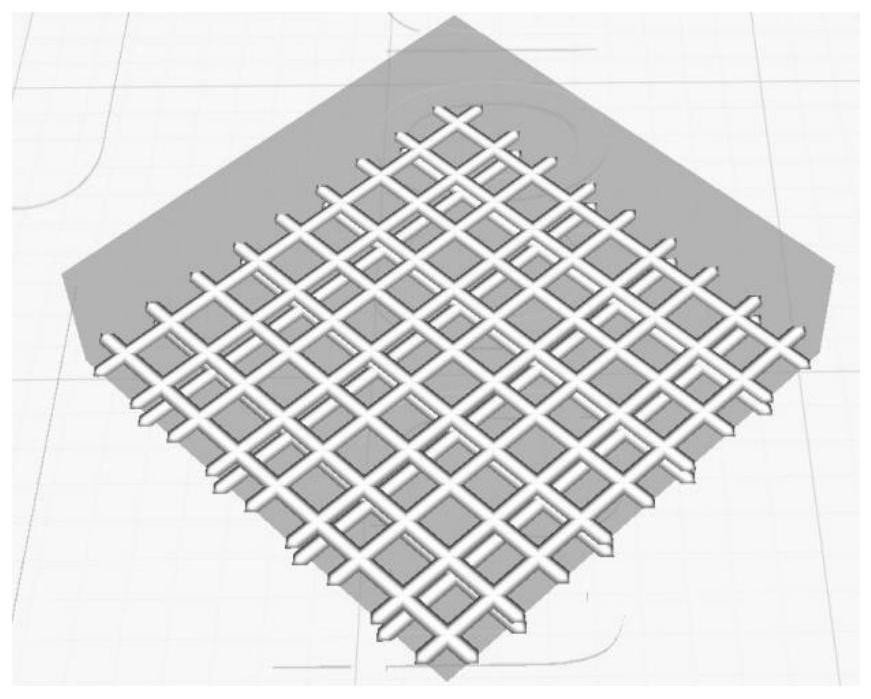

[0030] Step 1. Create a simple three-dimensional cube model, slice the three-dimensional model to obtain a series of two-dimensional cross-sectional slices, set the layer height to 0.8mm, fill the pattern with a grid grid structure, and fill the rate to 80%;

[0031] Step 2, pre-preparing the syringe and needle of the dispensing machine containing the slurry, the diameter of the needle is 0.8mm, the slurry is composed of about 80wt% of BTO ceramic base material, about 20wt% of PEGDA photosensitive resin, about 0.6wt% of photoinitiator TPO, About 1.6wt% of triton;

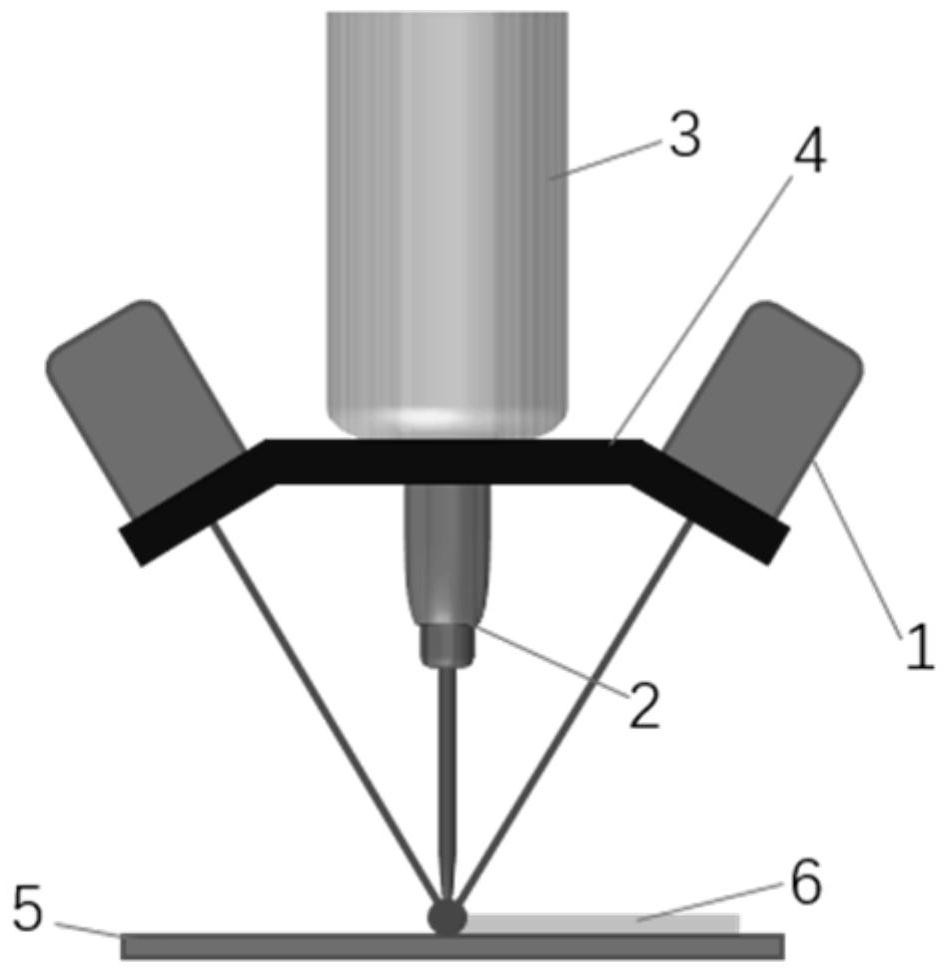

[0032] Step 3. Turn on the moving point light source according to the settings in step 1. The point light source moves synchronously with the printing needle, and the initial curing and finalization are performed synchronously during printing. The single...

Embodiment 2

[0036] In this embodiment, the method for preparing ceramic materials by direct writing 3D printing assisted by ultraviolet beam synchronous curing is as follows:

[0037] Step 1. Create a simple three-dimensional cube model; slice the three-dimensional model to obtain a series of two-dimensional cross-sectional slices, set the layer height to 0.4mm, fill the pattern with a grid grid structure, and fill the rate to 100%;

[0038] Step 2, pre-preparing the syringe and needle of the dispensing machine containing the slurry, the diameter of the needle is 0.8mm, the slurry is composed of about 80wt% of BTO ceramic base material, about 20wt% of PEGDA photosensitive resin, about 0.6wt% of photoinitiator TPO, About 1.6wt% of triton;

[0039] Step 3. Turn on the point light source according to the settings in step 1. The point light source moves synchronously with the printing needle, and the initial curing and finalization are carried out synchronously during printing. The single-lay...

Embodiment 3

[0043] In this embodiment, the method for preparing ceramic materials by direct writing 3D printing assisted by ultraviolet beam synchronous curing is as follows:

[0044] Step 1, establish a simple three-dimensional cube model, slice the three-dimensional model to obtain a series of two-dimensional cross-sectional slices, set the layer height to 0.8mm, fill the pattern to zigzag zigzag, and fill the rate to 50%;

[0045] Step 2, pre-preparing the syringe and needle of the dispensing machine containing the slurry, the diameter of the needle is 0.8mm, the slurry is composed of about 80wt% of BTO ceramic base material, about 20wt% of PEGDA photosensitive resin, about 0.6wt% of photoinitiator TPO, About 1.6wt% of triton;

[0046] Step 3. According to the settings in step 1, turn on the moving point light source. The point light source moves synchronously with the printing needle, and the initial curing and shaping are performed synchronously during printing. The double-layer cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com