A kind of method that sol-gel method prepares vanadium pentoxide film

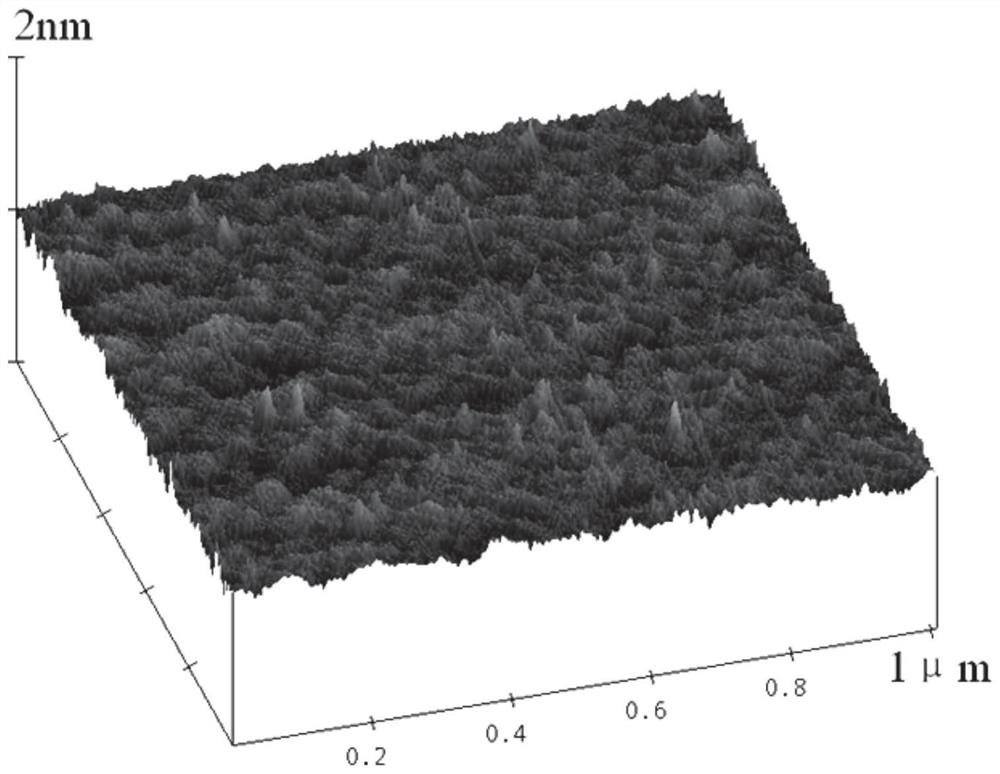

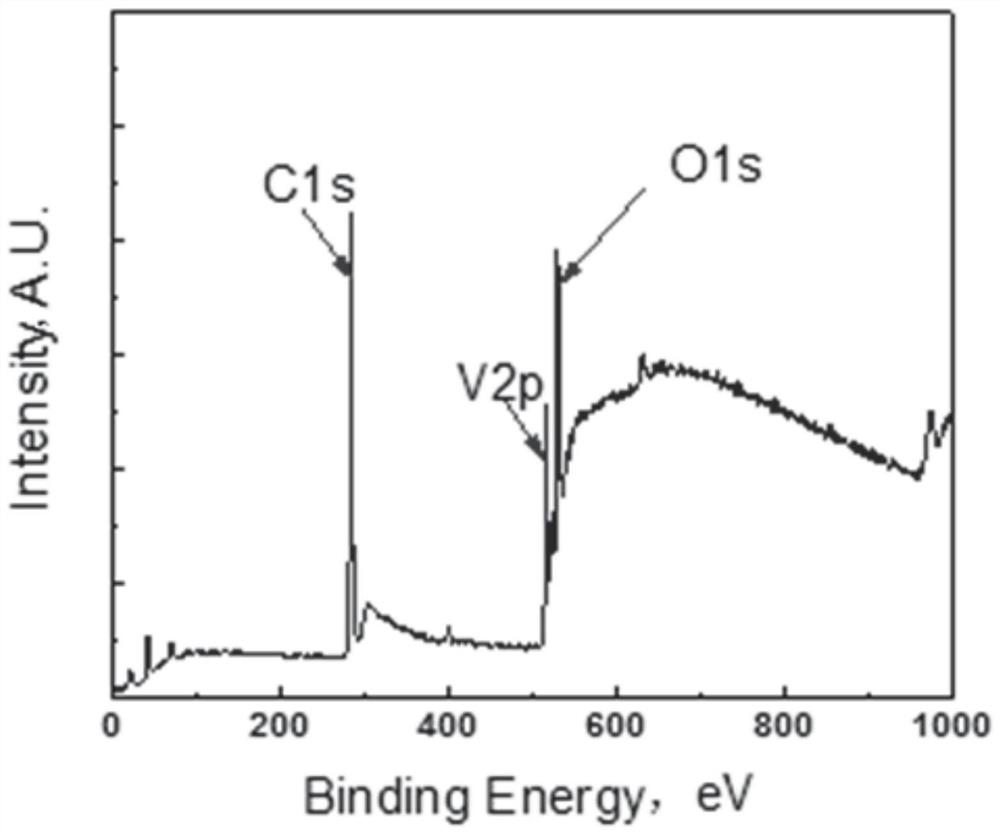

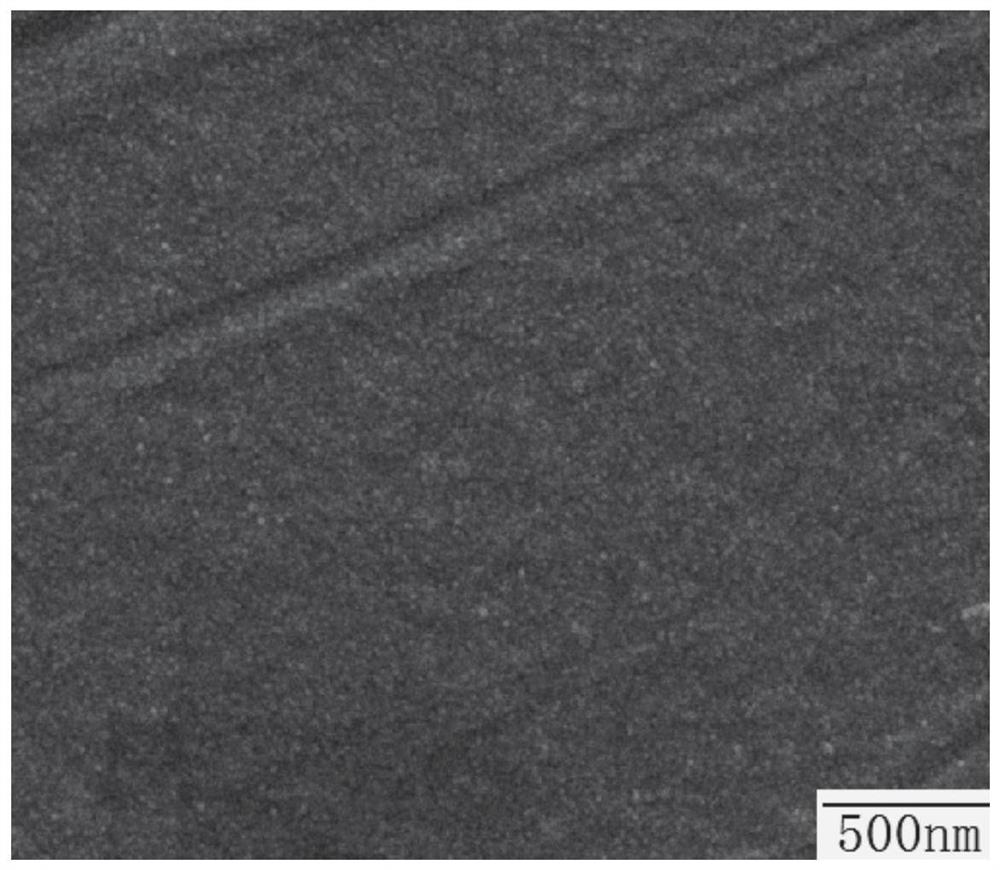

A technology of vanadium pentoxide and gel method, applied in vanadium oxide and other directions, can solve the problems of rough and porous thin film, low deposition rate, and many oxygen vacancies in thin film, and achieve dense and smooth surface, simple preparation process and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Embodiment 1: The method for preparing vanadium pentoxide thin film by a sol-gel method described in this embodiment is carried out according to the following steps:

[0026] 1. Preparation of V 2 O 5 Sol:

[0027] Add VOCl to absolute ethanol 3 liquid, stir evenly, let stand for 5min~20min, get VO(OC 2 H 5 ) 3 solution, under stirring conditions, to VO(OC 2 H 5 ) 3 Distilled water was added dropwise to the solution and stirred to obtain V 2 O 5 Sol, finally aged to give aged V 2 O 5 sol;

[0028] The VOCl 3 The molar ratio of liquid to absolute ethanol is 1:(100~400); the VOCl 3 The molar ratio of liquid to distilled water is 1:(5~50);

[0029] 2. Deposition of film:

[0030] ①、Using the film forming method, the aged V 2 O 5 The sol is formed into a film on the substrate, and then heat-treated for 0.5h to 1.5h at a temperature of 100°C to 300°C to obtain a single layer of V 2 O 5 film;

[0031] The substrate is obtained by successively ultrasonic c...

specific Embodiment approach 2

[0039] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in step 1, under the stirring condition of the rotation speed of 50 rpm to 200 rpm, the VO(OC) 2 H 5 ) 3 Distilled water was added dropwise to the solution. Others are the same as the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that: in step 1, under stirring conditions, the dripping rate is 0.05mL / s~2mL / s, and the VO(OC) 2 H 5 ) 3 Distilled water was added dropwise to the solution. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com