Organic silicon heat-conducting pouring sealant and preparation method thereof

A heat-conducting potting, silicone technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor defoaming, brittleness, loss of elasticity, etc., to improve hardness and tensile ability , The effect of improving curing performance and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

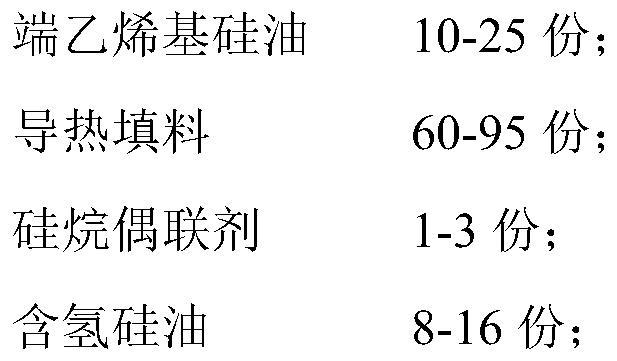

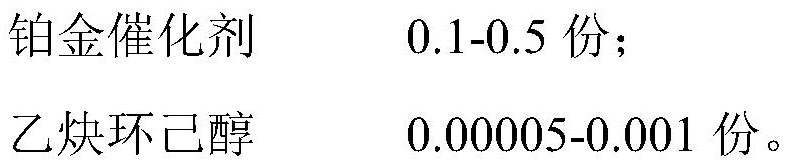

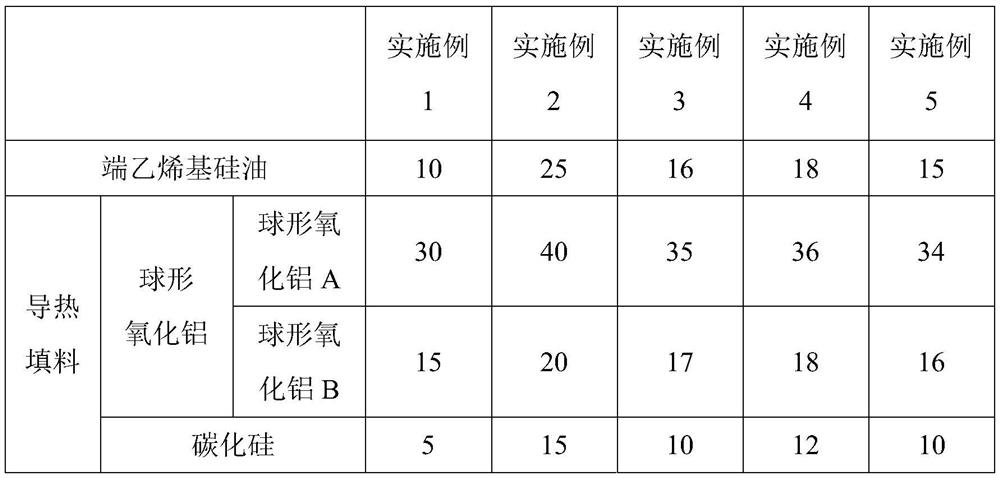

[0028] Table 1 shows the parts by weight of each component of the silicone thermal conductive potting compound in Examples 1-5.

[0029] The parts by weight of each component of the silicone thermal conductive encapsulant in Table 1 Examples 1-5

[0030]

[0031]

[0032] In Examples 1-5, the vinyl content in the vinyl terminated silicone oil is 0.1-1%; the mesh number of spherical alumina A is 200-300 mesh, and the mesh number of spherical alumina B is 2000-2500 mesh; silicon carbide The mesh number of aluminum hydroxide is 300-500 mesh; the mesh number of aluminum hydroxide is 1000-2000 mesh; the silane coupling agent is methyltrimethoxysilane; The hydrogen content of the silicone oil is 0.1-0.5%; the platinum catalyst is a platinum(0)-divinyltetramethyldisiloxane complex with a platinum content of 5000ppm.

[0033] The preparation method of the silicone thermal conductive potting compound in the embodiment 1-5 comprises the following steps:

[0034] S1. Mix the viny...

Embodiment 6-10

[0037] Table 2 shows the parts by weight of each component of the silicone thermal conductive encapsulant in Examples 6-10.

[0038] The parts by weight of each component of the silicone thermal conductive encapsulant in Table 2 Examples 6-10

[0039]

[0040]

Embodiment 6

[0042] The preparation method of the silicone thermal conductive potting compound in the embodiment 6 comprises the following steps:

[0043] S1. After mixing the vinyl-terminated silicone oil, spherical alumina A, silicon carbide, aluminum hydroxide and silane coupling agent, place it in an environment with a vacuum degree of -0.1--0.09MPa and 160°C, and stir and mix for 4 hours to obtain a mixture ;

[0044] S2. Pour in cooling water, stir and cool the mixture to 50°C, and divide it into material A and material B evenly. After adding platinum catalyst to material A, stir and mix through a 100-mesh sieve for packaging, and add end of material to material B. After the hydrogen-containing silicone oil, the side-containing hydrogen-containing silicone oil and acetylene cyclohexanol are stirred and mixed, pass through a 100-mesh sieve for packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com