Preparation method and application of polyethylene glycol s-triazine derivative leather tanning agent

A technology of polyethylene glycol and s-triazine, which is applied in the field of preparation of polyethylene glycol-s-triazine derivative tanning agents, can solve the problem of low reaction efficiency of terminal aldehyde products, lack of rigidity of chain structure, and poor crosslinking stability and other problems, to achieve the effect of plump hand feeling, obvious thickening and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

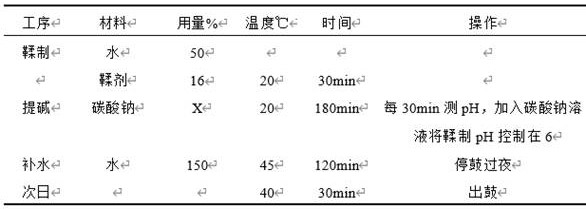

Method used

Image

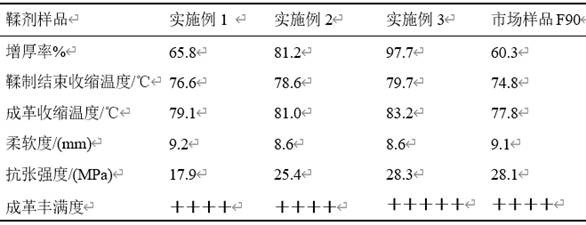

Examples

Embodiment 1

[0022] Add 200ml of acetone to a three-necked flask with a tetrafluoro stirring rod, weigh 23.9g of cyanuric chloride and add it to the three-necked flask, stir and dissolve in a cold water bath (0~5℃), while stirring and add dried anhydrous sodium carbonate 8.8 g, weigh 14.1g of dried polyethylene glycol 200 and add it to a constant pressure separatory funnel, adjust the dripping speed and add it dropwise to the stirring reaction solution in 30min, pour out the reaction mother solution after 7.5h of reaction, and filter the filtrate in a vacuum The solvent was concentrated on a rotary evaporator with a temperature of 0.08 MPa and a temperature of 20° C. to remove the solvent, an appropriate amount of water was added to dissolve, and the pH value was adjusted to 5-7 with an alkali to obtain a polyethylene glycol s-triazine derivative tanning agent.

Embodiment 2

[0024] Add 200ml of acetone to a three-necked flask with a tetrafluoro stirring rod, weigh 23.9g of cyanuric chloride into the three-necked flask, stir and dissolve in a cold water bath (0~5℃), and then add dried anhydrous 8.8g of sodium carbonate, weigh 42.1g of dried polyethylene glycol 600, add it to a constant pressure separatory funnel, adjust the dropping rate at 30min and add it dropwise to the stirring reaction solution, introduce nitrogen protection, and pour out after 8.5h of reaction The reaction mother liquor was filtered, the filtrate was concentrated on a rotary evaporator with a vacuum degree of 0.08 MPa and a temperature of 20 ° C to remove the solvent, an appropriate amount of water was added to dissolve, and the pH value was adjusted to 5-7 with an alkali to obtain polyethylene glycol s-triazine derivative tanning agent.

Embodiment 3

[0026] Add 250ml of toluene into a three-necked flask with a tetrafluoro stirring rod, weigh 23.9g of cyanuric chloride and add it to the three-necked flask, stir and dissolve in a cold water bath (0~5℃), and then add dried hydroxide Sodium 6.1g, weigh 56.2g of dried polyethylene glycol 800, add it to a constant pressure separatory funnel, adjust the dropping rate and add it dropwise to the stirring reaction solution in 30min, introduce nitrogen protection, react for 8.5h and pour out the reaction solution The mother liquor is filtered, the filtrate is concentrated on a rotary evaporator with a vacuum degree of 0.08 MPa and a temperature of 20 ° C to remove the solvent, an appropriate amount of water is added to dissolve, and the pH value is adjusted to 5-7 with an alkali to obtain a polyethylene glycol s-triazine derivative tanning agent .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com