In-situ observation method for morphology of non-metallic inclusions in ultra-pure non-oriented cold-rolled silicon steel

A technology of non-metallic inclusions and cold-rolled silicon steel, which is applied in the field of in-situ observation of a very small amount of micron-sized inclusions in ultra-pure non-oriented cold-rolled silicon steel, and can solve the problem of complex sample preparation, small field of view, and three-dimensional non-metallic inclusions. Difficult appearance and other problems, to achieve the effect of simple operation and good observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

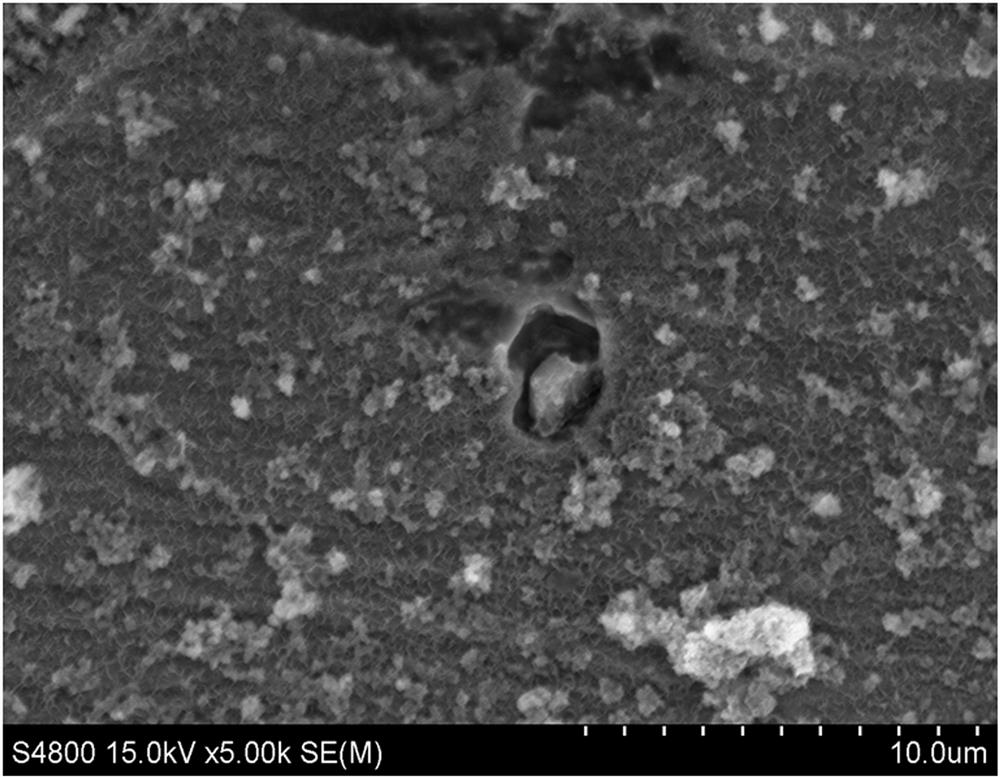

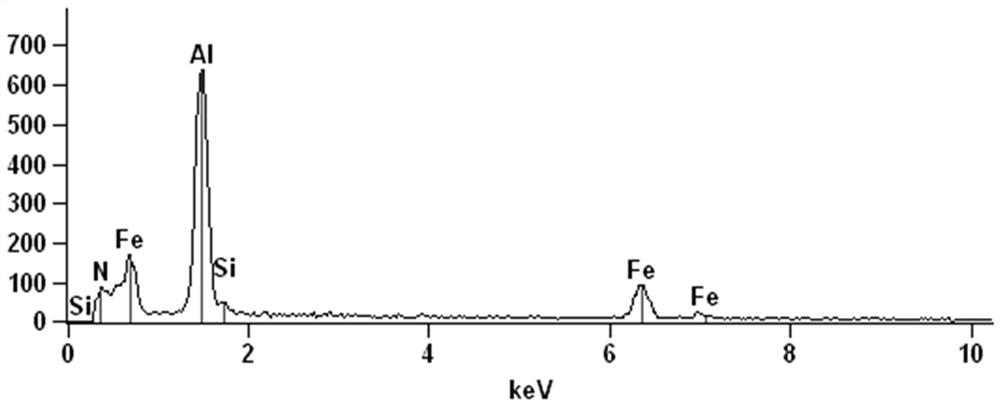

[0027] Adopt the technical scheme of the present invention, analyze the finished product of 35TWV1900 high-grade non-oriented cold-rolled silicon steel with a thickness of 0.35mm, process the sample into a size of 20mm×30mm, use 240#, 400#, 600#, 800# on the surface to be tested, After grinding with 1000# sandpaper, perform mechanical polishing and clean the surface with 99.99% alcohol in an ultrasonic instrument. Use a three-electrode electrolytic cell (reference electrolysis: saturated calomel electrode, auxiliary electrode: metallic platinum mesh) and an electrochemical workstation to carry out potentiodynamic polarization experiments. Electrolyte: take 1000ml deionized water and completely dissolve 30g NaCl in it. 6h CO 2 Gas to saturation, add appropriate amount of NaHCO 3 and triethanolamine as a stabilizer to adjust the pH to 6.2. Electrochemical setting parameters: open circuit: 1h, potentiodynamic polarization test: scan rate: 0.9 mV / S, test range: VS. SCE -0.8 V ~ ...

Embodiment 2

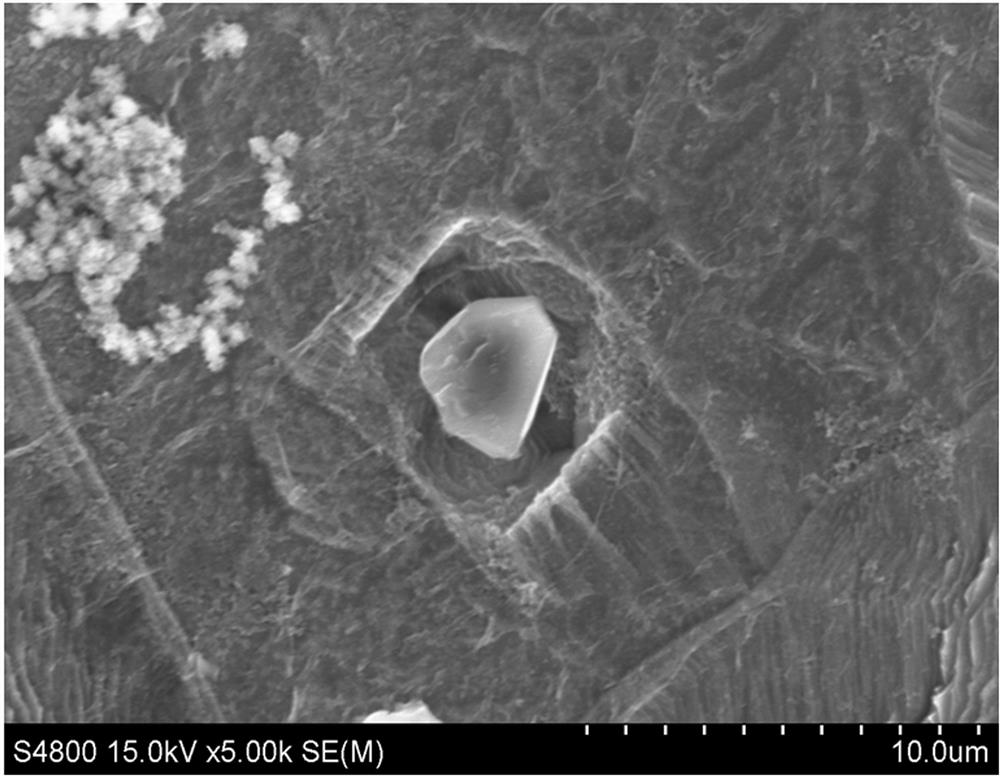

[0030] Adopt the technical scheme of the present invention, analyze the finished product of 35TWV1900 high-grade non-oriented cold-rolled silicon steel with a thickness of 0.35mm, process the sample into a size of 20mm×30mm, use 240#, 400#, 600#, 800# on the surface to be tested, After grinding with 1000# sandpaper, perform mechanical polishing and clean the surface with 99.99% alcohol in an ultrasonic instrument. Use a three-electrode electrolytic cell (reference electrolysis: saturated calomel electrode, auxiliary electrode: metallic platinum mesh) and an electrochemical workstation to conduct potentiodynamic polarization experiments. Electrolyte: take 1000ml deionized water and completely dissolve 50g KCl in it. 6h CO 2 Gas to saturation, add appropriate amount of NaHCO 3 and triethanolamine as a stabilizer to adjust the pH to 6.0. Electrochemical setting parameters: open circuit: 1.5h, first scan rate: 0.9 mV / S, test range: VS. SCE -0.8 V ~ -0.6 V potentiodynamic polariz...

Embodiment 3

[0033] Adopt the technical scheme of the present invention, analyze the finished product of 35TWV1900 high-grade non-oriented cold-rolled silicon steel with a thickness of 0.35mm, process the sample into a size of 20mm×30mm, use 240#, 400#, 600#, 800# on the surface to be tested, After grinding with 1000# sandpaper, perform mechanical polishing and clean the surface with 99.99% alcohol in an ultrasonic instrument. Use a three-electrode electrolytic cell (reference electrolysis: saturated calomel electrode, auxiliary electrode: metallic platinum mesh) and electrochemical workstation to carry out potentiodynamic polarization experiments. Electrolyte: take 1000ml deionized water, mix 60g ZnCl 2 Completely dissolve in it, pass 6h CO 2 Gas to saturation, add appropriate amount of NaHCO 3 and triethanolamine as a stabilizer to adjust the pH to 6.3. Electrochemical setting parameters: open circuit: 0.5 h, first scan rate: 0.9 mV / S, test range: VS. SCE -0.8 V ~ -0.6 V potentiodynami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com