Preparation method of graphene photocatalyst, product and application

A photocatalyst and graphene technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve low quantum yields, limited applications, and no micro Problems such as photocatalysts for pollutants, to achieve the effect of increasing the level of free radicals, fast electron transfer rate, and good solar light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of anthraquinone-2-sodium sulfonate / graphene airgel photocatalyst comprises the following steps:

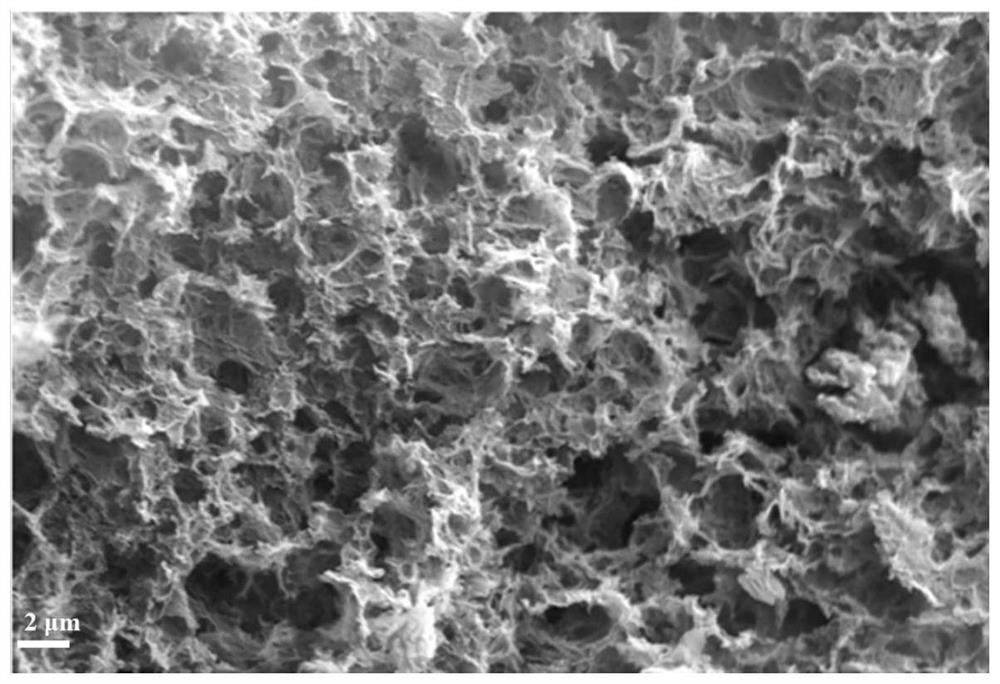

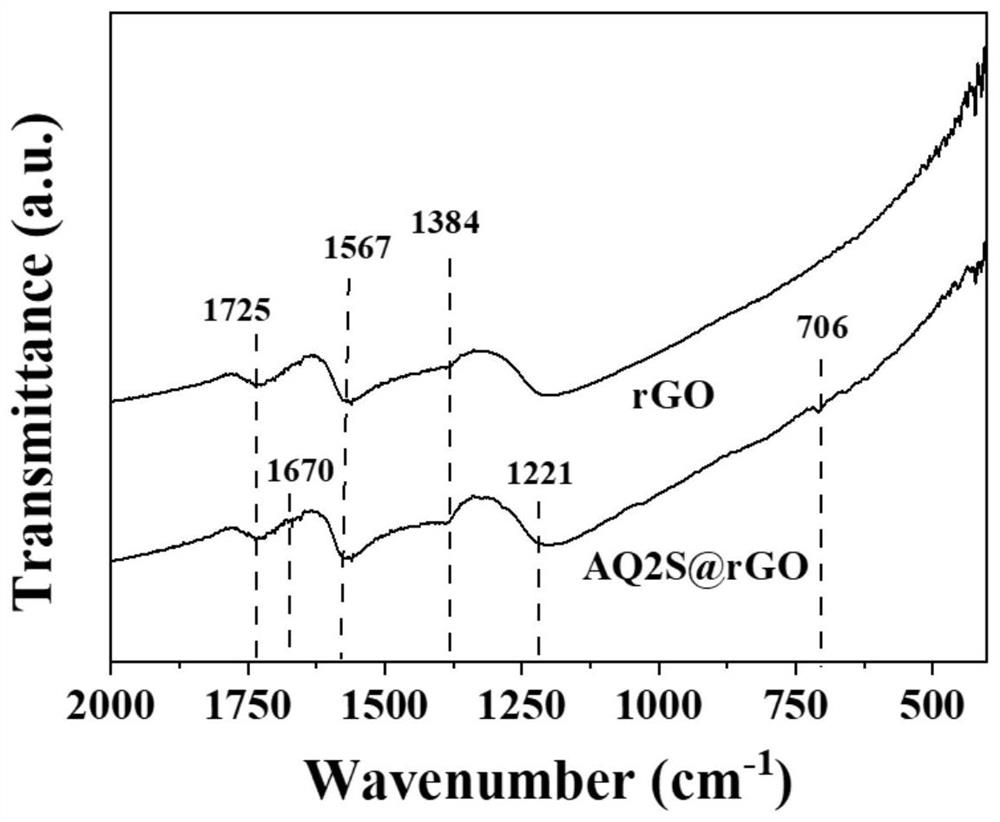

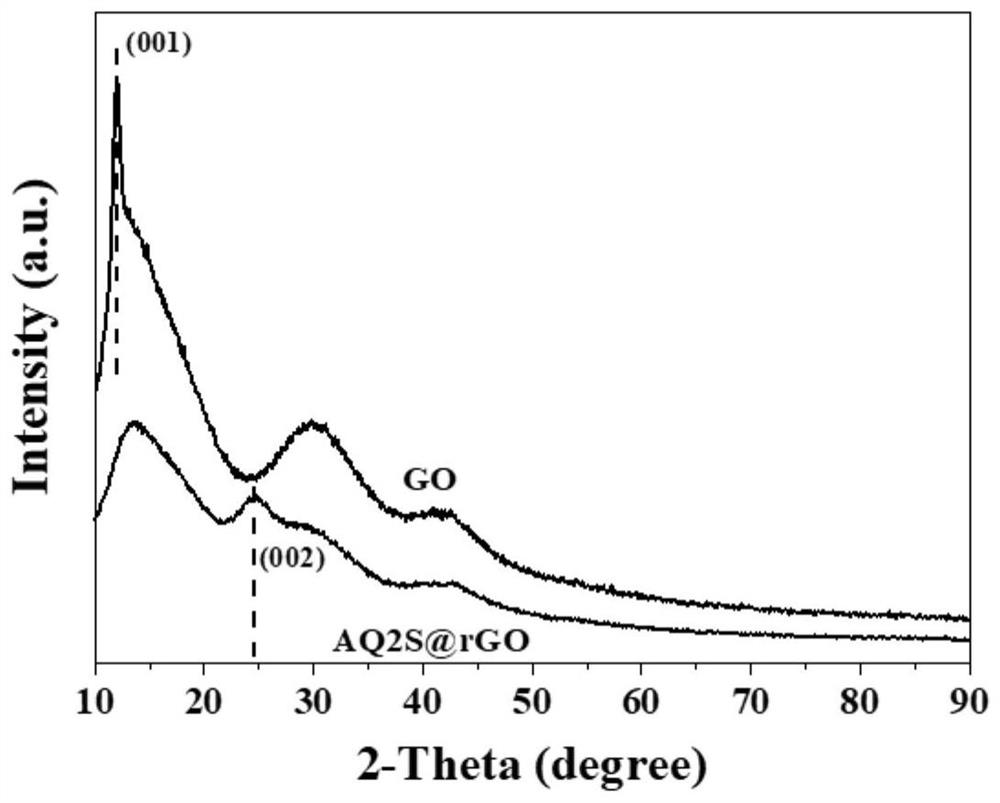

[0043] Disperse 0.050g graphene oxide (GO) in 25mL deionized water, and disperse evenly by ultrasonication for 120min to obtain a graphene oxide dispersion; add 0.0050g anthraquinone-2-sodium sulfonate (AQ2S) to the graphene oxide dispersion , and then magnetically stirred for 6 hours to disperse evenly to obtain a composite solution; put the composite solution into a 50mL stainless steel hydrothermal reactor and heat at 180°C for 12h; wash the hydrogel formed after the reaction with deionized water, Freeze-dry for 24 hours to obtain sodium anthraquinone-2-sulfonate / graphene airgel photocatalyst (AQ2S@rGO).

Embodiment 2

[0045] The preparation of anthraquinone-2-sodium sulfonate / graphene airgel photocatalyst, the steps are as follows:

[0046]Disperse 0.50g GO in 500mL deionized water and disperse evenly by ultrasonication for 100min to obtain a graphene oxide dispersion; add 0.0050g AQ2S to the graphene oxide dispersion, and then magnetically stir for 6h to disperse evenly to obtain a composite solution; Put it into a stainless steel hydrothermal reactor and heat at 120°C for 15h; the hydrogel formed after the reaction was washed with deionized water, and freeze-dried at -50°C for 24h to obtain AQ2S@rGO.

Embodiment 3

[0048] The preparation of anthraquinone-2-sodium sulfonate / graphene airgel photocatalyst comprises the following steps:

[0049] Disperse 0.250g GO in 50mL deionized water and disperse evenly by ultrasonication for 150min to obtain a graphene oxide dispersion; add 0.0050g AQ2S to the graphene oxide dispersion, and then magnetically stir for 6h to disperse evenly to obtain a composite solution; Put it into a stainless steel hydrothermal reactor and heat at 200°C for 10h; the hydrogel formed after the reaction was washed with deionized water, and freeze-dried at -50°C for 24h to obtain AQ2S@rGO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com