Bacteriostatic laundry fragrance-retaining bead and preparation method thereof

A technology of fragrant beads and essence, applied in the field of daily chemical detergent, can solve the problem of not having mites and antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The mite and antibacterial agent is made by the following steps:

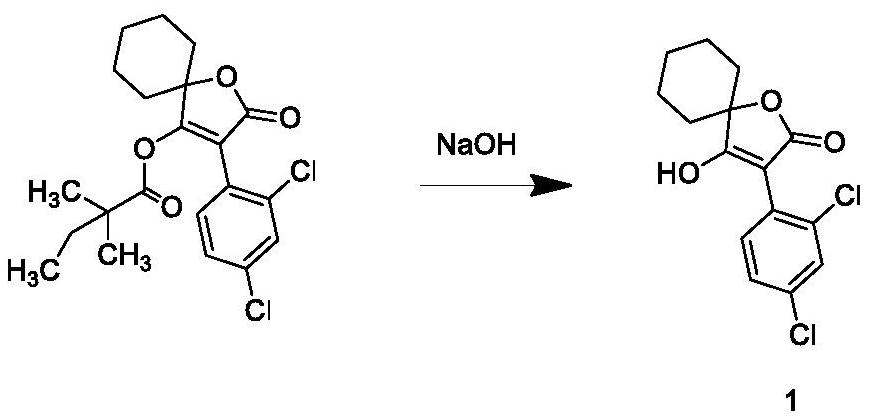

[0039] Step 1. Add 0.05mol spirodiclofen, 45.7mL isopropanol, 35mL water and 0.1g sodium hydroxide into a three-necked flask, raise the temperature to 55°C, stir and react for 1h, after the reaction is completed, filter, and extract the filtrate with ethyl acetate , removing ethyl acetate by distillation under reduced pressure to obtain intermediate 1;

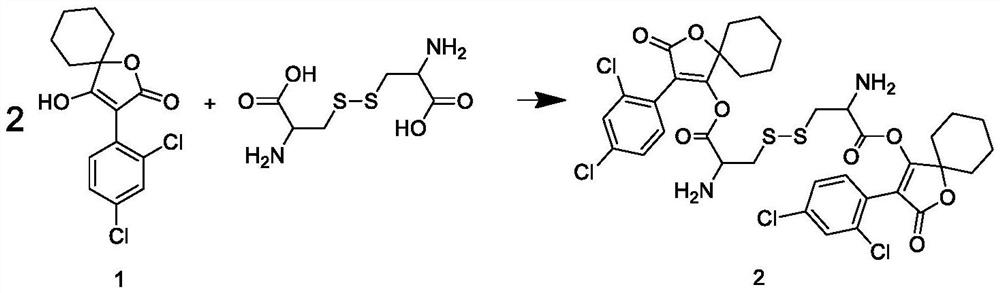

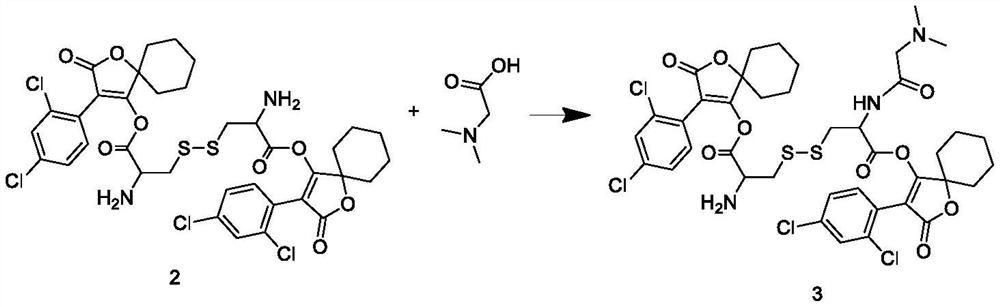

[0040] Step 2. Add 0.04mol intermediate 1, 45.7mL dimethyl sulfoxide and 15mL cystine solution into the reaction kettle, add concentrated sulfuric acid dropwise at a speed of 100r / min, control the reaction temperature at 80°C, and stir for 2h , the reaction is finished, the reaction product is washed with deionized water, extracted with ethyl acetate, and the ethyl acetate is removed by distillation under reduced pressure to obtain intermediate 2, wherein the cystine solution is composed of cystine and 10% mass fraction of acetic acid solution according ...

Embodiment 2

[0047] The mite and antibacterial agent is made by the following steps:

[0048] Step 1. Add 0.05mol spirodiclofen, 48.2mL isopropanol, 36mL water and 0.2g sodium hydroxide into a three-necked flask, raise the temperature to 58°C, stir and react for 1.5h, after the reaction, filter, and the filtrate is washed with ethyl acetate Extraction, removal of ethyl acetate by distillation under reduced pressure, to obtain intermediate 1;

[0049] Step 2. Add 0.04mol intermediate 1, 46.7mL dimethyl sulfoxide and 18mL cystine solution into the reaction kettle, add concentrated sulfuric acid dropwise at a speed of 150r / min, control the reaction temperature at 86°C, and stir for 2.5 h, the reaction is finished, the reaction product is washed with deionized water, extracted with ethyl acetate, and the ethyl acetate is removed by distillation under reduced pressure to obtain intermediate 2, wherein the cystine solution is composed of cystine and 10% mass fraction of acetic acid solution acco...

Embodiment 3

[0056] The mite and antibacterial agent is made by the following steps:

[0057] Step 1. Add 0.05mol of spirodiclofen, 51.2mL of isopropanol, 38mL of water and 0.3g of sodium hydroxide into a three-necked flask, raise the temperature to 60°C, stir and react for 2 hours, after the reaction, filter, and extract the filtrate with ethyl acetate , removing ethyl acetate by distillation under reduced pressure to obtain intermediate 1;

[0058] Step 2. Add 0.04mol intermediate 1, 48.5mL dimethyl sulfoxide and 20mL cystine solution into the reaction kettle, add concentrated sulfuric acid dropwise at a speed of 200r / min, control the reaction temperature at 90°C, and stir for 3h , the reaction is finished, the reaction product is washed with deionized water, extracted with ethyl acetate, and the ethyl acetate is removed by distillation under reduced pressure to obtain intermediate 2, wherein the cystine solution is composed of cystine and 10% mass fraction of acetic acid solution accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com