High-temperature-resistant integrated electrode for lithium ion battery and preparation method of high-temperature-resistant integrated electrode

A lithium-ion battery, high-temperature-resistant technology, applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of difficult to change polyolefin-based film temperature resistance difference, battery capacity attenuation, runaway, etc., to achieve high temperature Cycle performance and safety performance, simple preparation process and excellent safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

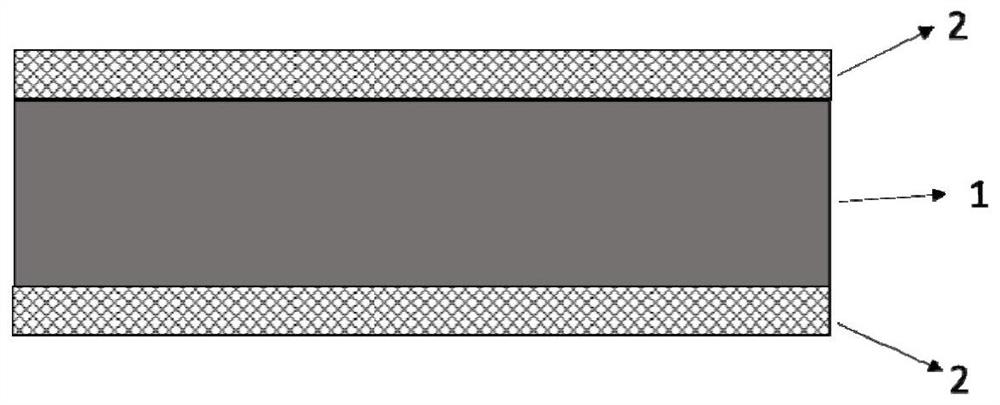

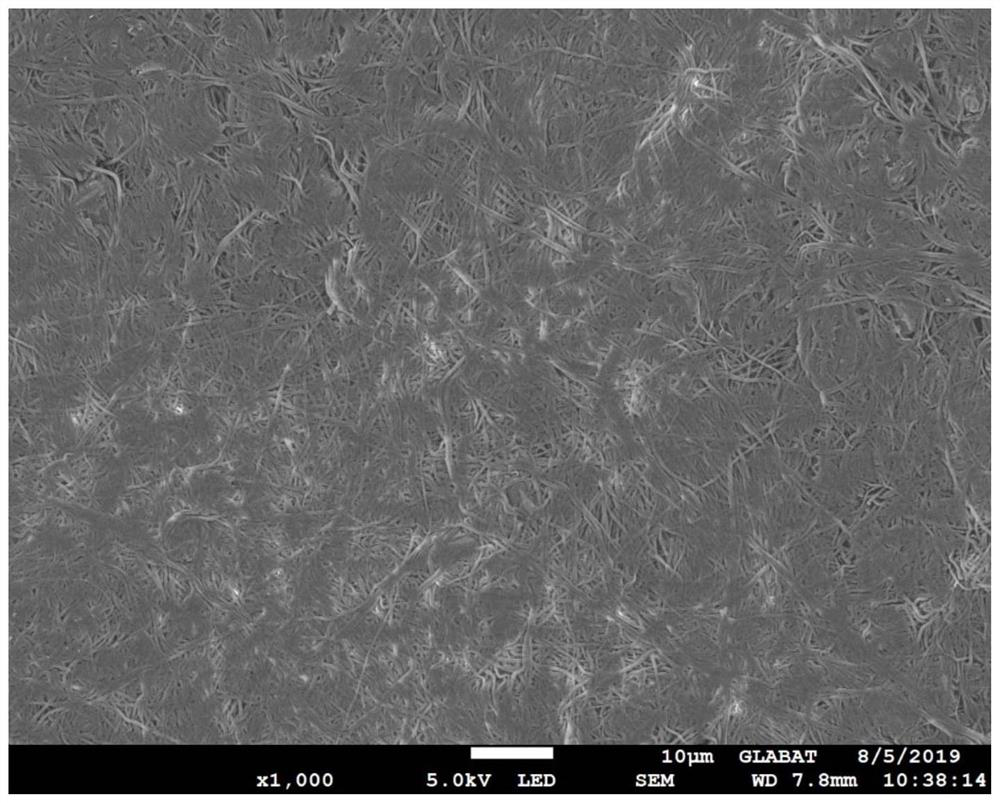

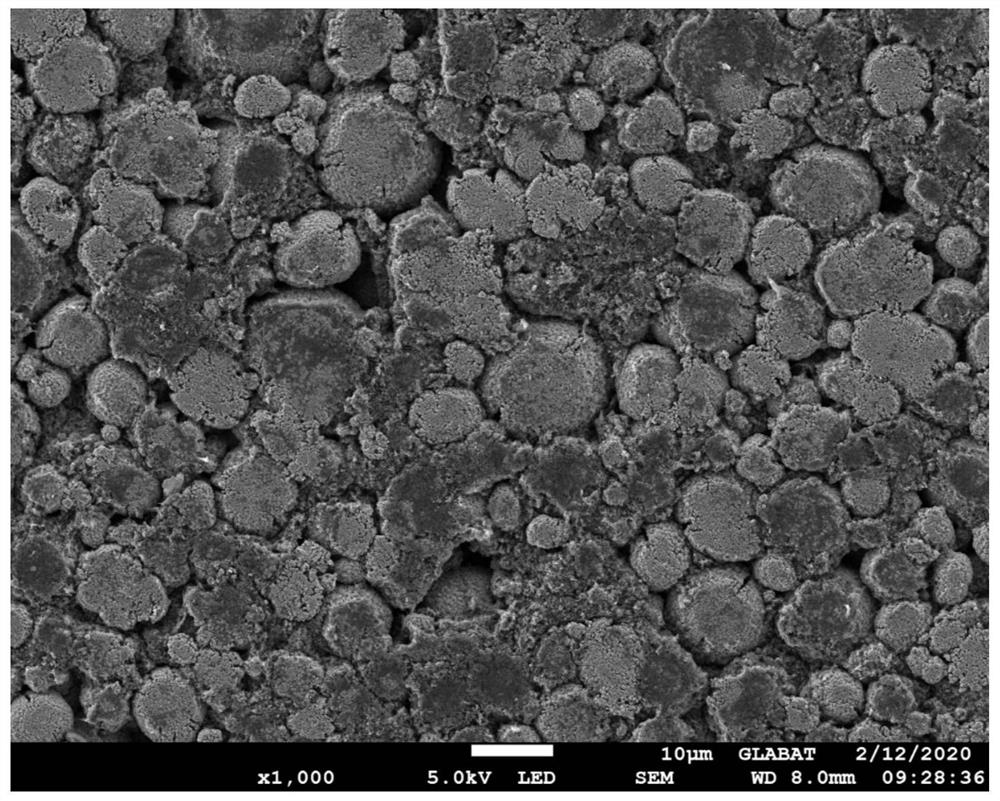

[0052] A high-temperature-resistant integrated electrode A, using 3% PI binder by mass to make 8-series NCM ternary material into a positive electrode sheet, and then using electrospinning technology to cover a layer of polymer nanofiber film layer on its surface Composite. Among them, the total thickness of the above-mentioned high-temperature-resistant integrated electrode is 155 μm, the thickness of the positive pole piece of 8-series NCM ternary material is 147 μm, and the thickness of the high-temperature-resistant polymer nanofiber film layer is 8 μm. The preparation method of the above-mentioned high-temperature-resistant integrated electrode A includes the following steps:

[0053] Step 1: Prepare the positive pole piece, synthesize the PAA solution, obtain a polyamic acid solution with a solid content of 20%, and prepare the polyamic acid solution into a glue solution with a solid content of 12%. Mix the positive electrode active material NCM811, conductive carbon bl...

Embodiment 1-2

[0058] Example 1-2, adjust the content of the PI binder of the pole piece in Example 1 to 8%, adjust the corresponding positive electrode proportion of conductive carbon black, and keep other conditions unchanged, cut into 12mm discs, roll, weigh, Dry in a vacuum oven at 200°C for 12 hours, assemble the button half-cell to test the electrical properties, 0.1C, the specific capacity is 190mAh / g, the first effect is 87.5%, and the capacity retention rate is 85% after 100 cycles.

Embodiment 1-3

[0059] Example 1-3, adjust the thickness of the nanofiber film in Example 1 to 3 μm, and keep other conditions unchanged, cut into 12 mm discs, roll, weigh, dry in a vacuum oven at 200°C for 12 hours, and assemble the button half-cell Tested electrical performance, 0.1C, specific capacity is 203mAh / g, first effect is 89.5%, cycled for 100 cycles, capacity retention rate is 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com