Multi-junction distributed feedback semiconductor laser and preparation method thereof

A distributed feedback, semiconductor technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of poor waveguide cross-section symmetry, large parasitic capacitance of devices, affecting fiber coupling, etc., to improve fiber coupling efficiency and reduce parasitic capacitance parameters. , the effect of high fiber coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific preparation Embodiment 1

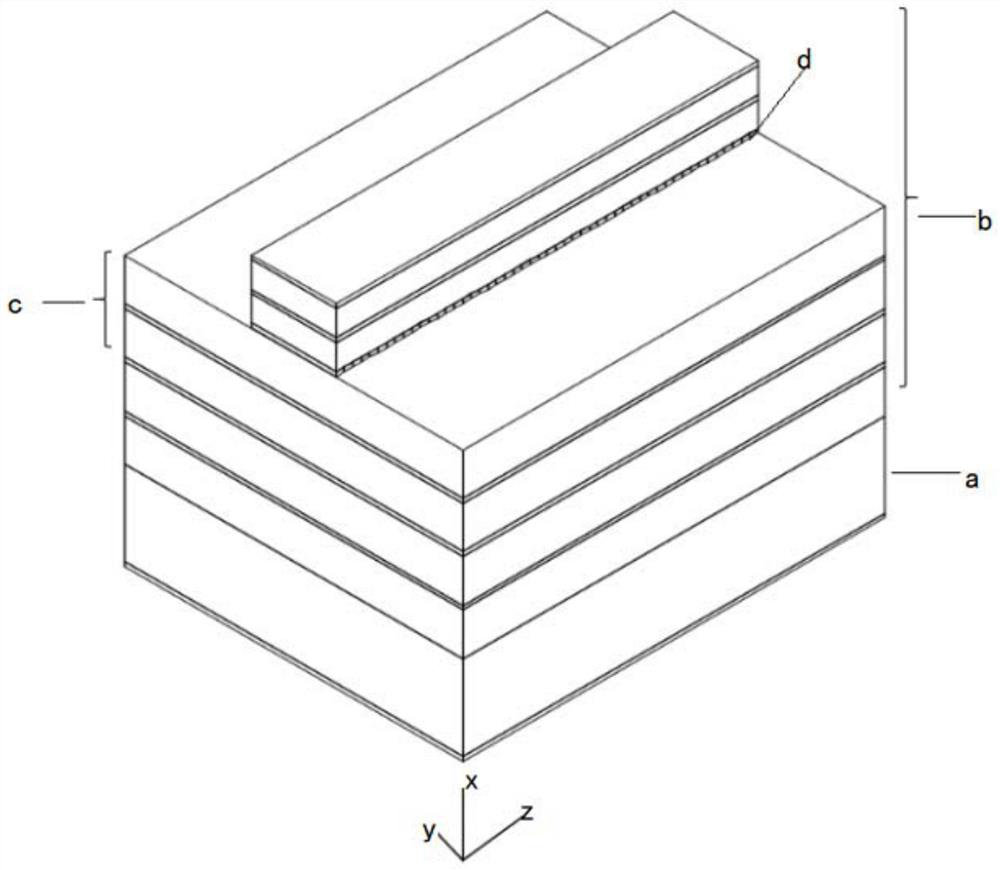

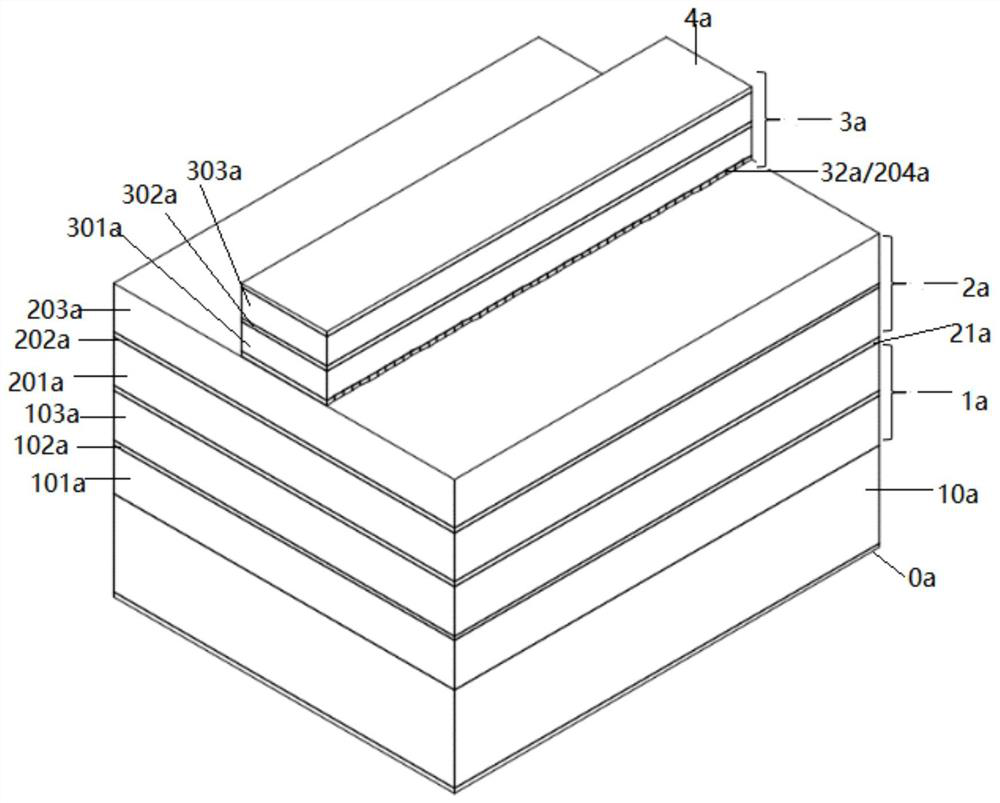

[0047] This specific embodiment introduces a preparation method of an InGaAsP / InP multi-junction distributed feedback semiconductor laser (DFB-LD) with a wavelength of 1550nm, as follows:

[0048] refer to figure 2 As shown, the following materials are epitaxially grown from bottom to top on a highly doped n-type InP substrate 10a: the first PN junction N region 101a is an n-type InP buffer layer (thickness 500nm, doping concentration about 1× 10 18 cm -3 ); the light-emitting region 102a of the first PN junction, wherein the light-emitting region 102a includes from bottom to top: a non-doped lattice matching InGaAsP lower waveguide layer (thickness 50nm, light fluorescence wavelength 1170nm), InGaAsP active layer multiple quantum wells ( 2 pairs of quantum wells, well width 8nm, 1% compressive strain, optical fluorescence wavelength 1700nm, barrier width 10nm, 0.2% tensile strain, optical fluorescence wavelength 1170nm), non-doped lattice matching InGaAsP upper waveguide l...

specific preparation Embodiment 2

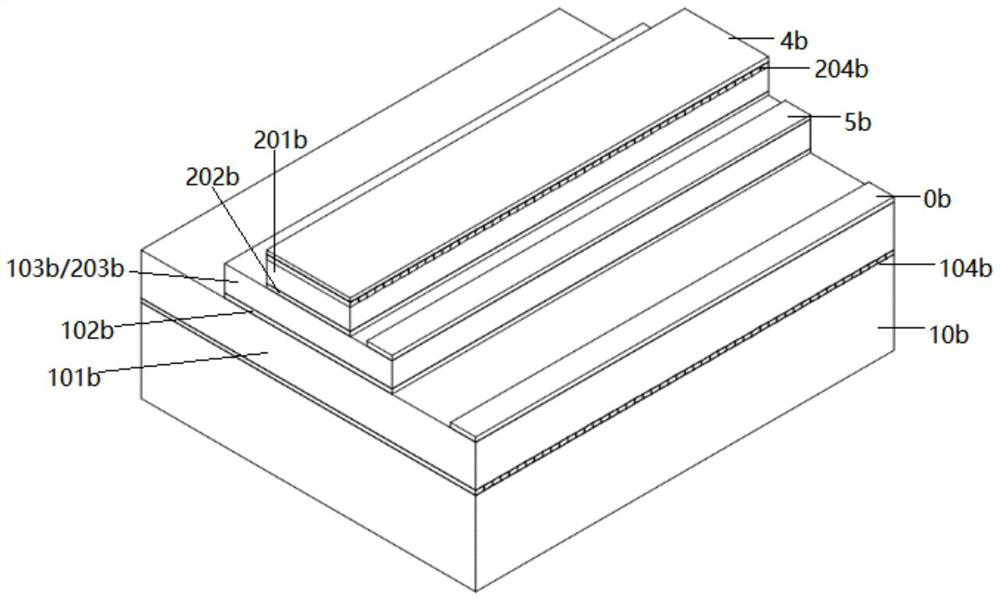

[0055] This embodiment introduces an AlGaInAs / InP multi-junction distributed feedback semiconductor laser (DFB-LD) with a wavelength of 1550 nm.

[0056] Such as image 3 As shown, the following materials are epitaxially grown once on a highly doped p-type InP substrate 10b: the grating layer 104b of the first PN junction is a p-type InGaAsP layer (thickness 10nm, doping concentration 1×10 18 cm -3 ).

[0057] The grating pattern formation process is as follows: on the basis of a primary epitaxial structure, a photoresist with a period range of 230-250nm first-order grating is formed by holographic interference lithography, electron beam lithography, nanoimprinting or projection lithography pattern. The grating pattern is transferred from the photoresist to the grating layer 104b of the first PN junction, that is, the p-type InGaAsP layer, by wet or dry etching technology.

[0058] After the grating pattern is made, the second epitaxial growth is performed, and the first P...

specific preparation Embodiment 3

[0067] This embodiment introduces an AlGaInAs / InP multi-junction distributed feedback semiconductor laser (DFB-LD) with a wavelength of 1310 nm.

[0068] refer to figure 2 , on a highly doped n-type InP substrate 10a, the following materials are epitaxially grown from bottom to top: the first PN junction N region 101a is an n-type InP buffer layer (thickness 500nm, doping concentration about 1×10 18 cm -3 ); the light-emitting region 102a of the first PN junction, the light-emitting region 102a comprises from bottom to top: non-doped lattice matching AlGaInAs lower waveguide layer (thickness 50nm, light fluorescence wavelength 1050nm), AlGaInAs active layer multiple quantum wells (2 For quantum wells, well width 8nm, 1% compressive strain, photofluorescent wavelength 1460nm, barrier width 10nm, 0.2% tensile strain, photofluorescent wavelength 1050nm), non-doped lattice matching AlGaInAs upper waveguide layer (thickness 20nm, photoluminescence wavelength 1050nm); the first P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com