Method for preparing metal cushion block for acetabular bone defect reconstruction through 3D printing

A 3D printing, metal pad technology, applied in the medical field, can solve the problems of effective reconstruction of difficult acetabular bone defects, difficult to guarantee the stability of the prosthesis, expensive metal pads, etc., to achieve the effect of effective reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Below will combine the appended in the embodiment of the present invention Figure 2-Figure 9 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. The specific embodiments described here are only used to explain the present invention, not to limit the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0075] Such as Figure 2-Figure 9 As shown, the present invention provides a method for preparing a metal spacer by 3D printing for reconstruction of acetabular bone defect, comprising the following steps:

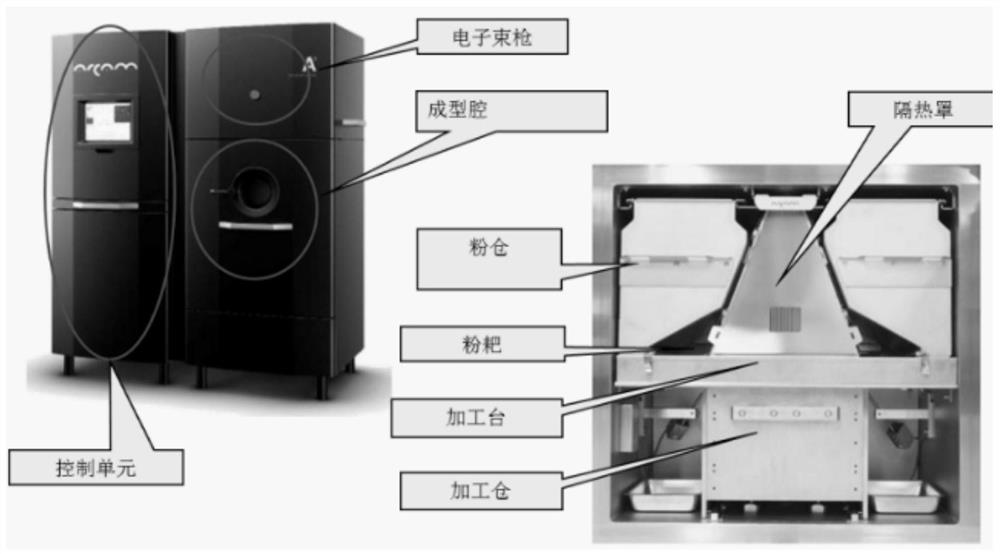

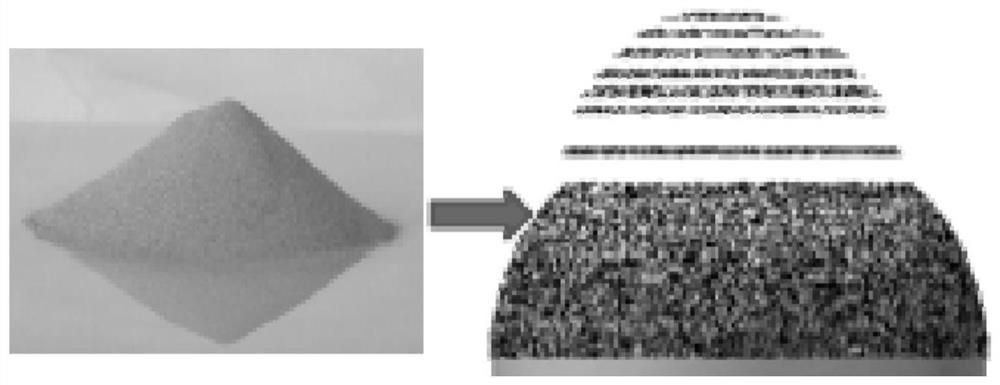

[0076] S1. Preparation, characterization and cytocompatibility testing of electron beam fusion 3D printed titanium implants;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com