Preparation method and application of novel biochar-based tar cracking catalyst

A tar cracking and biochar technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

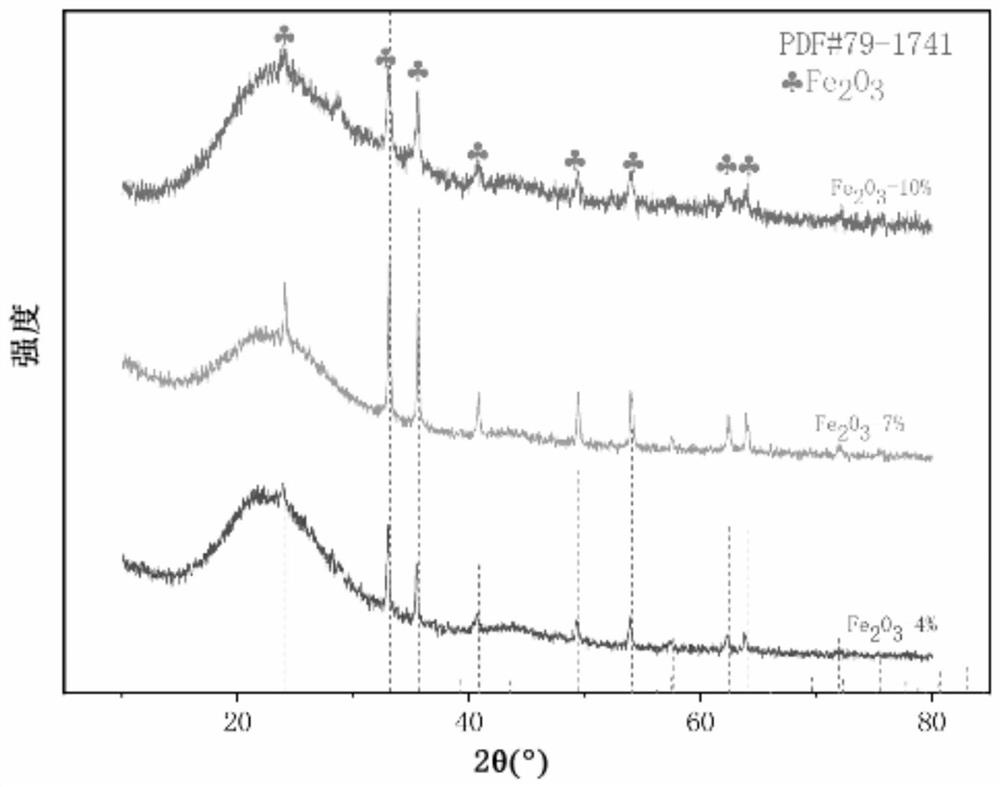

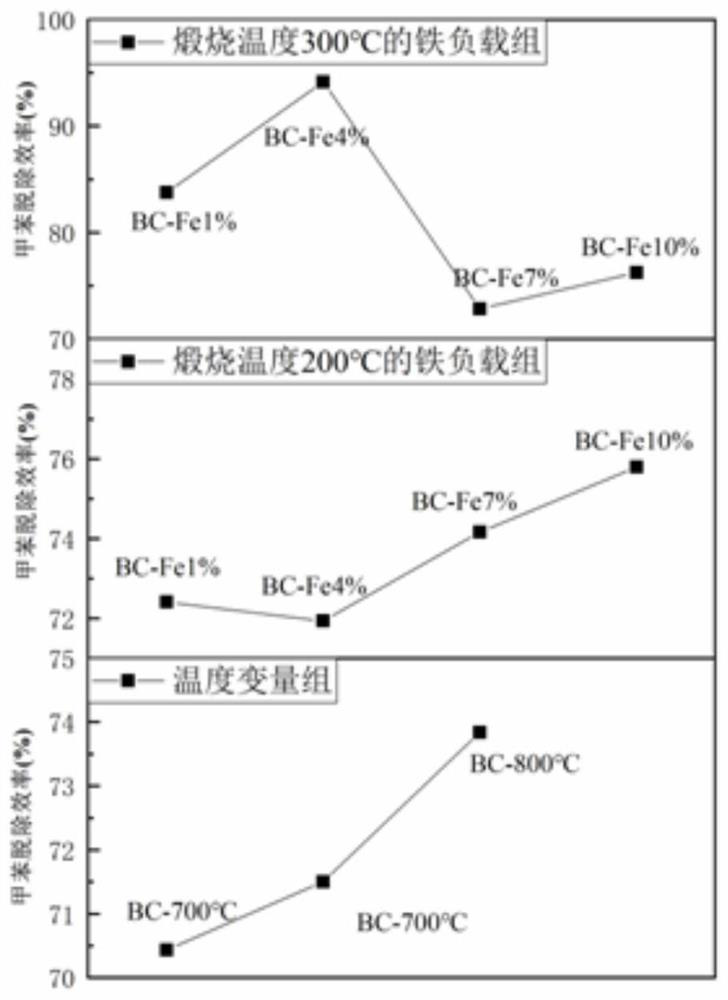

[0017] A preparation method of a novel biochar-based tar catalyst, the catalyst takes biochar as a carrier, and the surface supports Fe2O3, and its preparation steps are as follows:

[0018] a. Pretreatment of biomass raw materials: place the biomass raw material rice husks in an environment of 105°C to dry for 5-10 hours, and then use a pulverizer to process them into 0.2-0.8mm powders for later use.

[0019] b. Preparation of biochar: put a certain amount of rice husk powder in a fixed-bed reactor, feed a certain amount of nitrogen at the same time, raise the temperature of the reactor to 800-900°C, and maintain it for 10 minutes after reaching the target temperature. -30min; then switch nitrogen to a nitrogen / water vapor mixture for activation, where the concentration of water vapor is 5%-20%, the reaction temperature is adjusted to 700-900°C, and the activation time is 10min-60min. After the activation is complete, the reaction atmosphere is readjusted to a nitrogen atmosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com