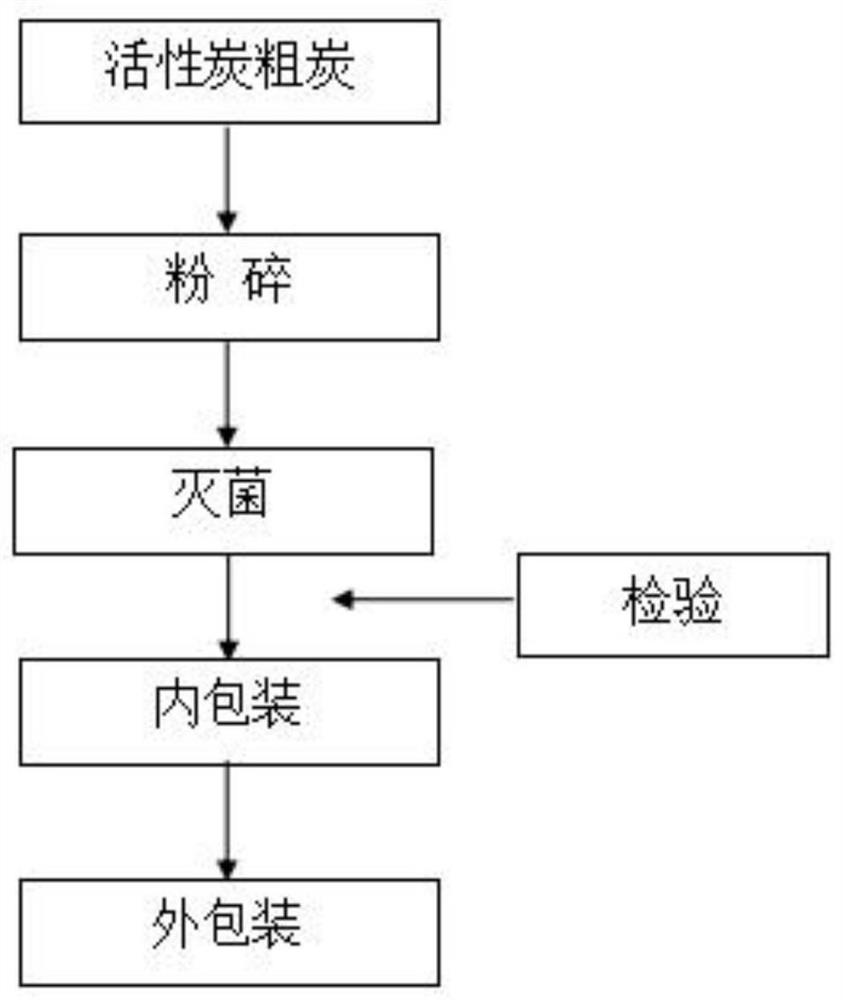

Production process of activated carbon for injection

A production process and technology of activated carbon, which are applied in sanitary equipment for toilets, mixers with rotary stirring devices, inorganic chemistry, etc. problems, to improve the uniformity and stirring efficiency, avoid self-ignition by heating, and avoid the increase of moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A production process of activated carbon for injection, comprising the steps of:

[0030] Step 1: After the activated carbon coarse carbon is qualified, it is put into a pendulum mill for crushing, and after being filtered by a filter screen, the crushed coarse carbon particles are obtained;

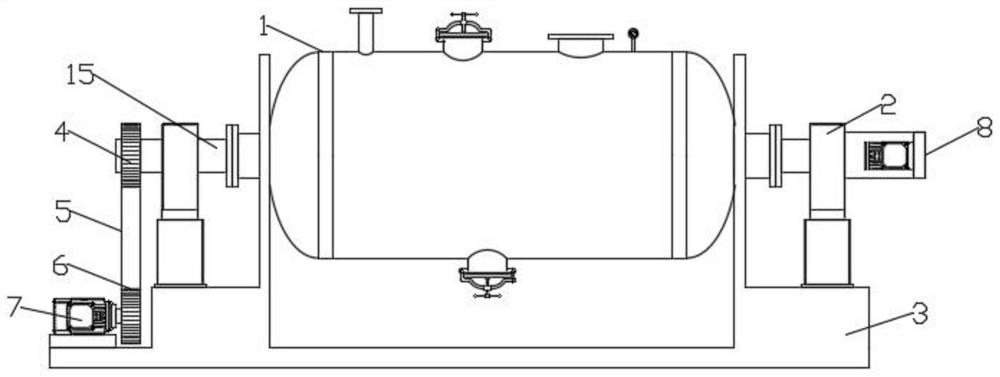

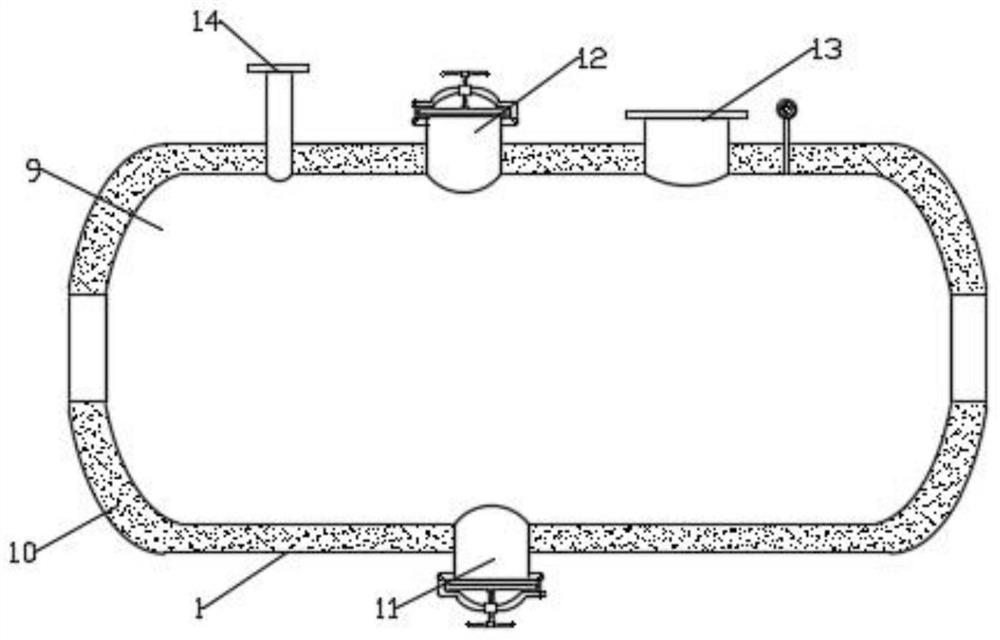

[0031] Step 2: put the pulverized coarse charcoal particles into the stirring chamber 9 from the feeding pipe 12 on the sterilizer to carry out vacuum sterilization, the temperature inside the sterilizer is set at 160°C, and the sterilizing stirring time is 120 minutes;

[0032] Step 3: Take the sterilized activated carbon powder for inspection, and pack it in a C-level purification environment after passing the inspection;

[0033] Step 4: Carry out outer packaging under normal temperature and sealed conditions, and finally prepare activated carbon for injection.

[0034] Specifically, the mesh number of the filter screen in step 1 is 200 mesh. The water content of the activate...

Embodiment 2

[0036] A production process of activated carbon for injection, comprising the steps of:

[0037] Step 1: After the activated carbon coarse carbon is qualified, it is put into a pendulum mill for crushing, and after being filtered by a filter screen, the crushed coarse carbon particles are obtained;

[0038] Step 2: Put the pulverized coarse charcoal particles into the mixing chamber 9 from the feed pipe 12 on the sterilizer for vacuum sterilization, set the temperature inside the sterilizer to 250°C, and the sterilizing and stirring time to be 45 minutes;

[0039] Step 3: Take the sterilized activated carbon powder for inspection, and pack it in a C-level purification environment after passing the inspection;

[0040] Step 4: Carry out outer packaging under normal temperature and sealed conditions, and finally prepare activated carbon for injection.

[0041] Specifically, the mesh number of the filter screen in step 1 is 240 mesh. The water content of the activated carbon po...

Embodiment 3

[0043] A production process of activated carbon for injection, comprising the steps of:

[0044] Step 1: After the activated carbon coarse carbon is qualified, it is put into a pendulum mill for crushing, and after being filtered by a filter screen, the crushed coarse carbon particles are obtained;

[0045]Step 2: Put the pulverized coarse charcoal particles into the mixing chamber 9 from the feeding pipe 12 on the sterilizer to carry out vacuum sterilization, the temperature inside the sterilizer is set at 180°C, and the sterilization stirring time is 60 minutes;

[0046] Step 3: Take the sterilized activated carbon powder for inspection, and pack it in a C-level purification environment after passing the inspection;

[0047] Step 4: Carry out outer packaging under normal temperature and sealed conditions, and finally prepare activated carbon for injection.

[0048] Specifically, the mesh number of the filter screen in step 1 is 220 mesh. The water content of the activated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com