Brominated polyisobutylene-p-methylstyrene rubber composition, preparation method thereof and vulcanized rubber

A technology of p-methyl styrene and brominated polyisobutylene, applied in brominated polyisobutylene-p-methyl styrene-based rubber composition and preparation thereof, and the field of vulcanizate, can solve the problem of reducing the degree of rubber crosslinking and increasing the interface phase. Compatibility and other issues to achieve the effect of improving the degree of vulcanization, improving interfacial compatibility, and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

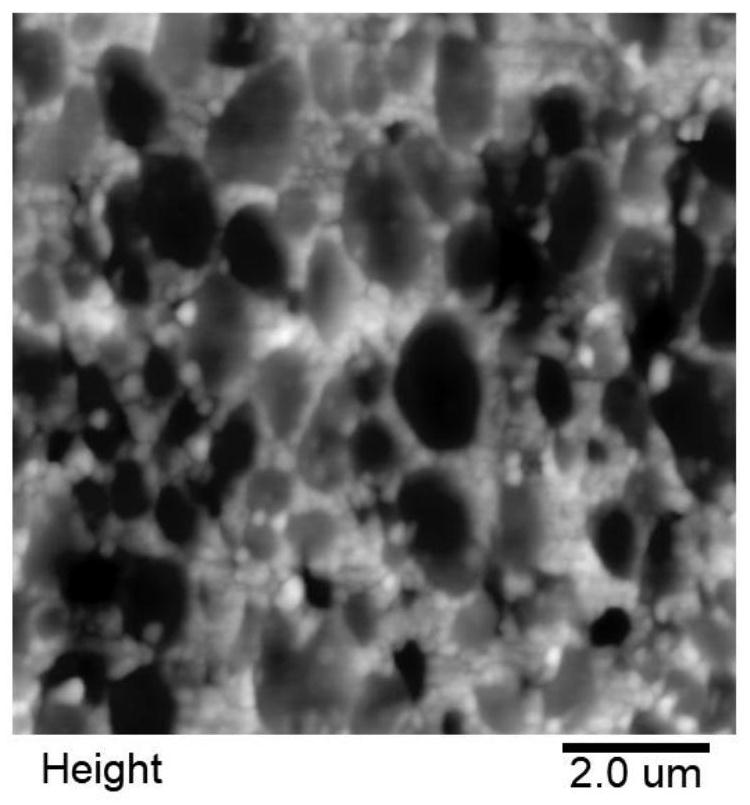

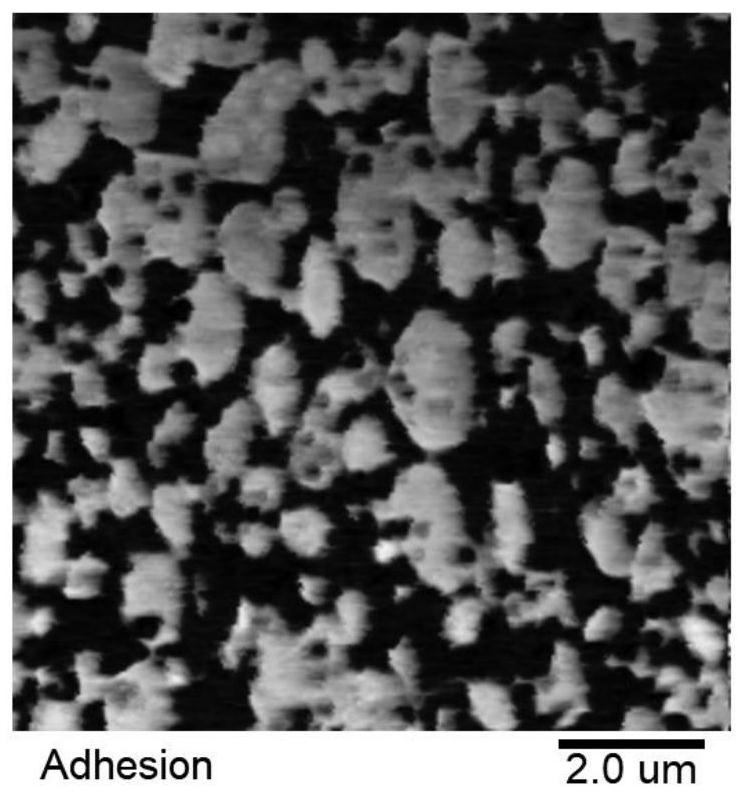

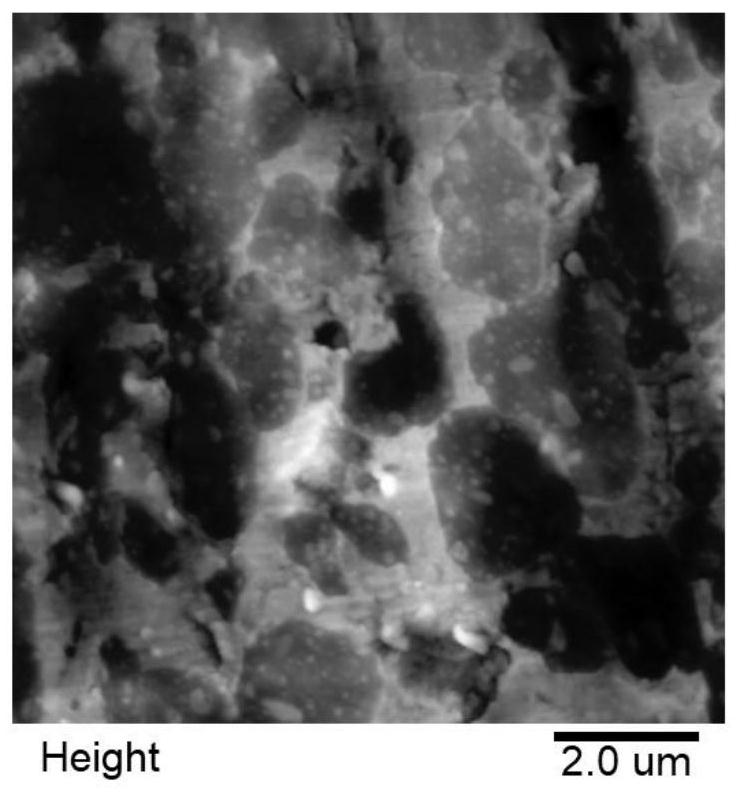

Image

Examples

Embodiment 1

[0065] The basic composition and weight of the selected raw materials are as follows:

[0066] Brominated polyisbutylene - methylstyrene rubber (grade 3745,

[0067] Exxon Mobil, BR content is 2.3 wt%, Menny viscosity is ml

[0068]

[0069]

[0070] According to the above formulation, the nylon is advanced, the blocking agent, catalyst, and antioxidants, and nylon are blended at 220 ° C for 8 minutes in the mesh; then carry out rubber and plastic premixing, polybutylene-pair Base-based rubber plastic is uniform, and then mixed with the nylon after 220 ° C for 10 min in the mesenchym, and then cool to room temperature, add a vulcanization system, mix well to obtain a brominated polyisbutylene - pair Base-based rubber composition;

[0071] Finally, dynamic vulcanization is performed, and the resulting brominated polyisobutylene is placed in a twin-screw extruder in a twin screw extruder, and the vulcanization temperature is 220 ° C, the rotational speed is 400 rpm, and the dyna...

Embodiment 2

[0074] The basic composition and weight of the selected raw materials are as follows:

[0075] Brominated polyisbutylene - methylstyrene rubber (grade 3745,

[0076] Exxon Mobil, BR content is 2.3 wt%, Menny viscosity is ml

[0077]

[0078]

[0079] The implementation steps are different from Example 1, and different is different amounts of the sealing agent octadecyl glycerol ether.

Embodiment 3

[0081] The basic composition and weight of the selected raw materials are as follows:

[0082] Brominated polyisbutylene - methylstyrene rubber (grade 3745,

[0083] Exxon Mobil, BR content is 2.3 wt%, Menny viscosity is ml

[0084]

[0085] The implementation steps are different from Example 1, and different is different amounts of the sealing agent octadecyl glycerol ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com