A kind of transparent polyamide resin and preparation method thereof

A technology of polyamide resin and polyamide, which is applied in the field of transparent polyamide and its preparation, can solve the problems of reducing crystallization ability, excessive crystallinity, weakening hydrogen bond between molecular chains, etc., achieve good heat resistance, improve transparency Luminous rate, effect of reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

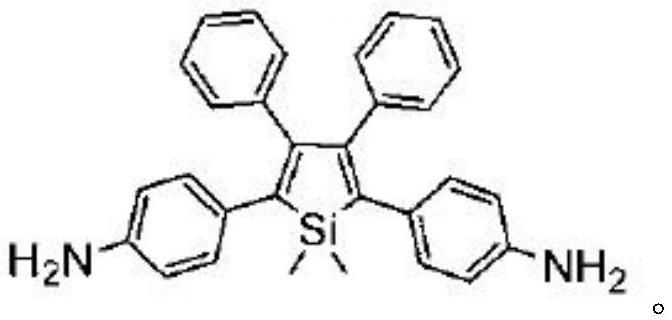

Method used

Image

Examples

Embodiment Construction

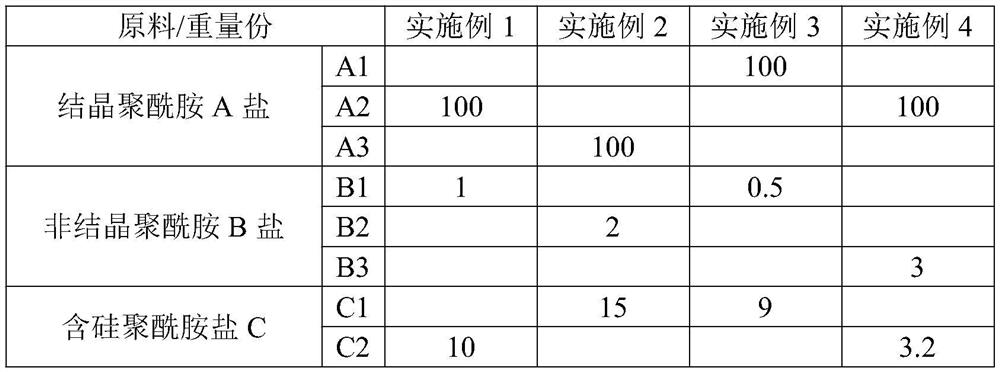

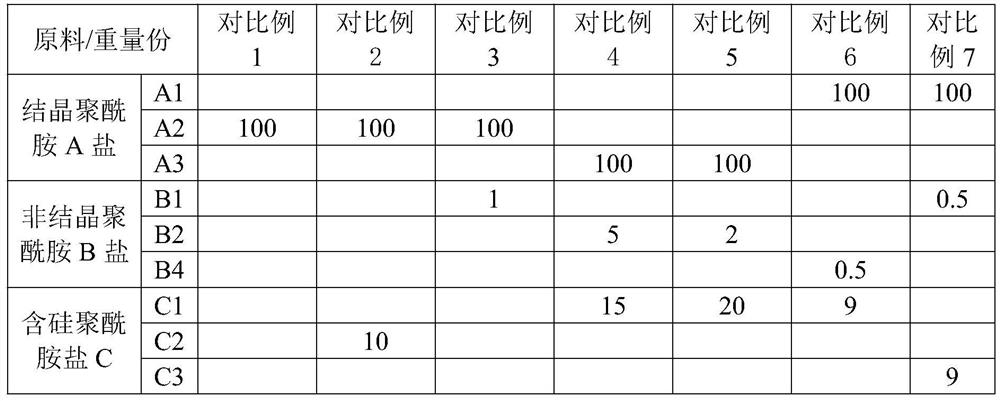

[0027] The principles and features of the present invention are described below in conjunction with implementation examples. The examples given are for the convenience of those skilled in the art to better understand the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

[0028] All raw materials involved in the examples of the present invention are commercially available.

[0029] Crystalline polyamide salt solution A1: the mass concentration of polyamide 66 salt is 50%, and the solvent is water;

[0030] Crystalline polyamide salt solution A2: the mass concentration of polyamide 610 salt is 50%, and the solvent is water;

[0031] Crystalline polyamide salt solution A3: the mass concentration of polyamide 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com