Multi-layer melt-blown non-woven fabric and preparation method thereof

A melt-blown non-woven fabric and melt-blown technology, which is applied in the direction of melt-spinning, chemical instruments and methods, textile/flexible product manufacturing, etc., can solve problems such as single function and difficulty in meeting the requirements of high-quality polymer melt-blown, and achieve Good filtering effect, good spinning effect, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

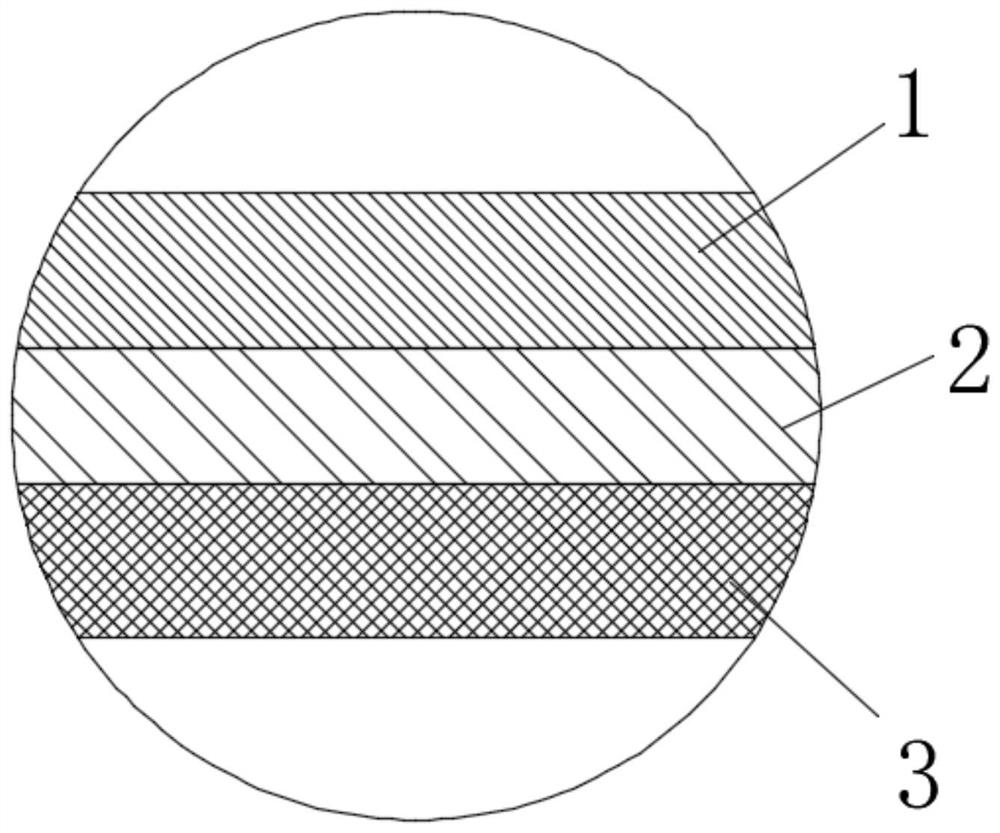

[0035] refer to figure 1 , in this embodiment, a multi-layer melt-blown non-woven fabric is proposed, the multi-layer melt-blown non-woven fabric is composed of an antibacterial outer layer 1, a filter interlayer 2, and a hydrophilic inner layer 3 arranged in sequence; the antibacterial outer layer Layer 1 is made of antibacterial polymer; antibacterial polymer is polymerized by polyhydric alcohol and guanidinium salt, and antibacterial polymer is prepared by following method: take ethylene glycol 100g, guanidine nitrate 220g, add in reaction kettle, mix well, under nitrogen protection , adjusted the pH to 5 with hydrochloric acid, heated to 120°C, reacted for 3 hours, then added 25g of acrylic acid, carried out the esterification reaction for 1.5 hours, and finished the reaction to obtain it; the filter interlayer 2 is composed of polyacrylonitrile-based carbon fiber and composite mineral fiber ; The hydrophilic interlayer 3 is formed by melt-blowing modified resin slices.

...

Embodiment 2

[0038] The modified resin chip is made of the following raw materials in parts by weight: 45 parts of polypropylene chip, 15 parts of polybutylene terephthalate chip, 5 parts of chlorinated biphenyl, 4 parts of molybdenum disulfide, nanometer Au36 (SCH2CH3) 24 0.8 copies of clusters;

[0039] Preparation of modified resin slices: put polypropylene slices and polybutylene terephthalate slices in a vacuum oven to dry; dry polypropylene slices, polybutylene terephthalate slices, Benzene, molybdenum disulfide, nano Au 36 (SCH 2 CH 3 ) 24 The clusters are blended in the twin-screw extruder, and the melt stream is condensed in the water tank, then air-dried by the air dryer, pelletized by the pelletizer, and the modified resin slices are obtained; the drying temperature in the vacuum oven is set at 100-120°C, The drying time is 30-60min;

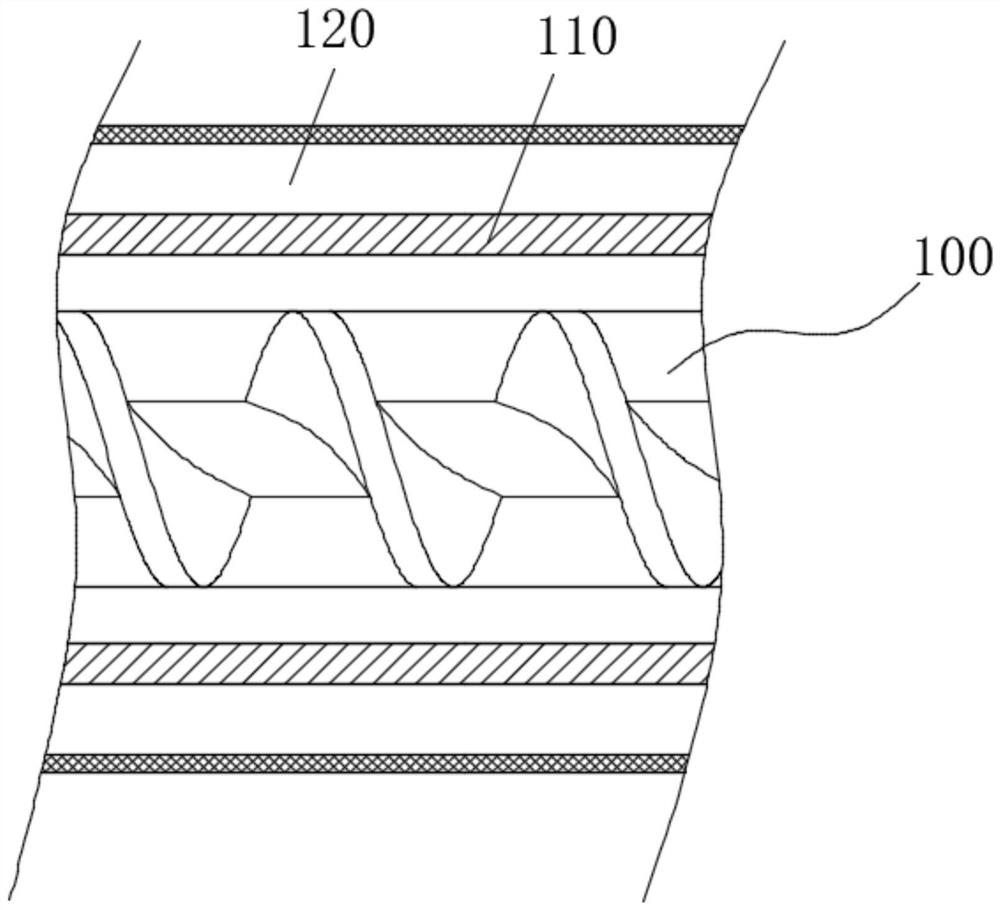

[0040]Resin chip melt blowing: feed the dried modified resin chip into the screw extruder, and after being melted by the heating tube, it wi...

Embodiment 3

[0045] In this embodiment, a method for preparing a multi-layer melt-blown nonwoven fabric is proposed, comprising the following steps:

[0046] S1: Antibacterial melt-blown non-woven fabrics, filter melt-blown non-woven fabrics and hydrophilic melt-blown non-woven fabrics were prepared using a melt-blown machine;

[0047] S2: The antibacterial melt-blown non-woven fabric, the filter melt-blown non-woven fabric and the hydrophilic melt-blown non-woven fabric are laminated from the outside to the inside to obtain the melt-blown non-woven fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com