Preparation method of gas chromatographic column and chromatographic instrument device with gas chromatographic column

A gas chromatographic column and stationary phase technology, applied in the field of gas chromatography, can solve the problems of high price, threat to human health, separation and detection of trans fatty acid isomers, etc., and achieve the effect of reducing content and ensuring human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

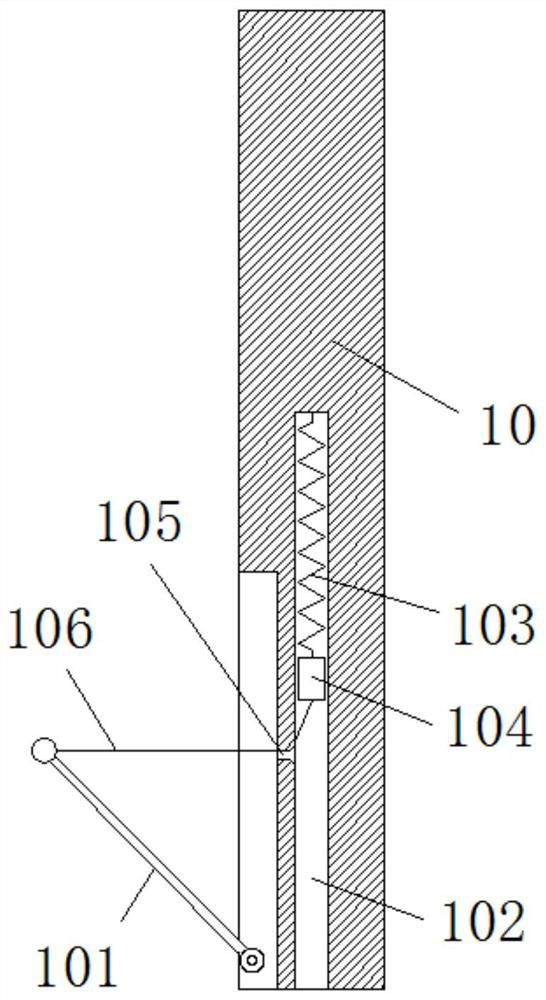

[0049] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

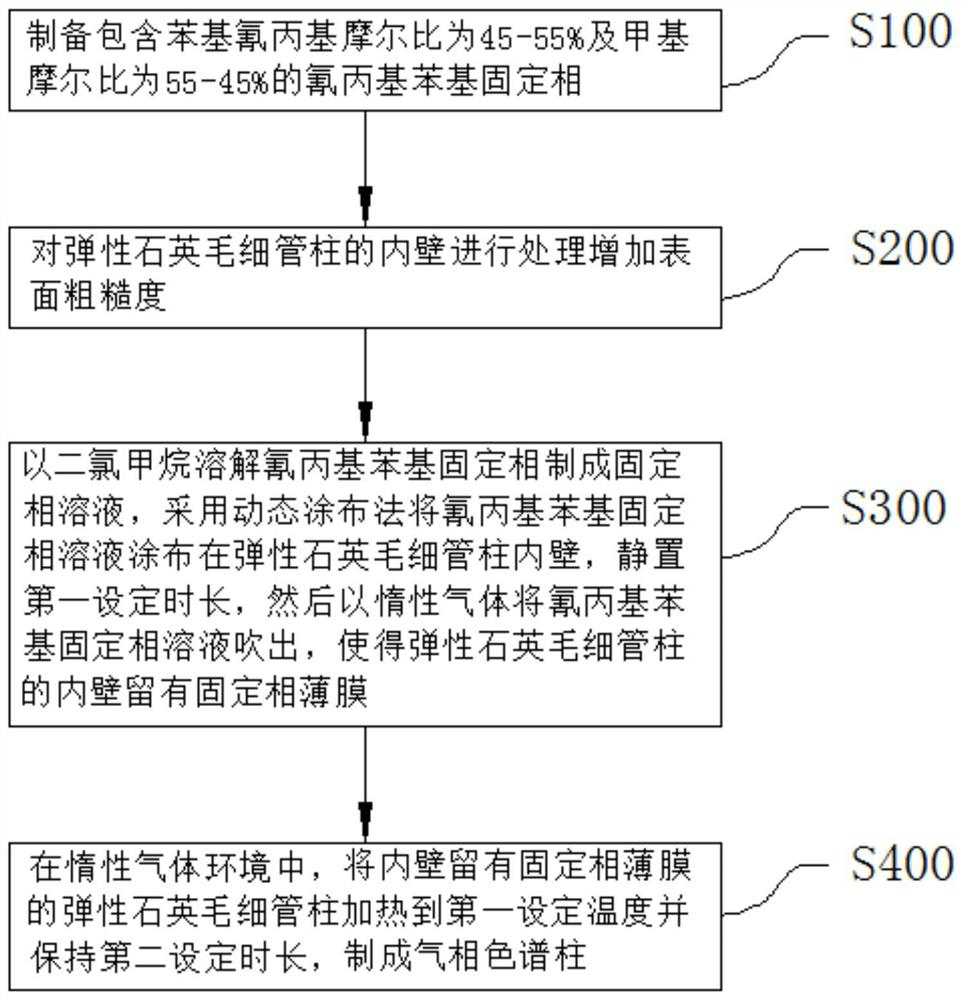

[0050] Such as figure 1 Shown, the embodiment of the present invention provides a kind of preparation method of gas chromatography column, comprises the following steps:

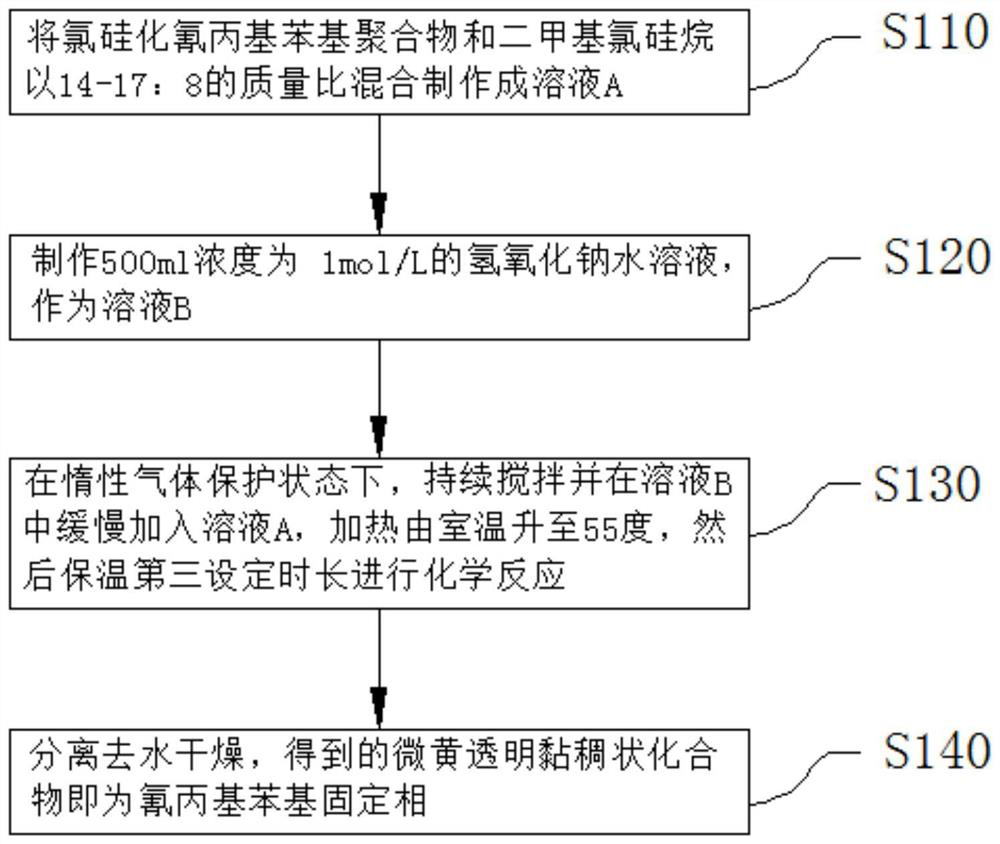

[0051] S100 prepares a cyanopropylphenyl stationary phase comprising 45-55% benzocyanopropyl molar ratio and 55-45% methyl molar ratio:

[0052]

[0053] S200 treats the inner wall of the elastic quartz capillary column to increase the surface roughness;

[0054] S300 uses dichloromethane to dissolve the cyanopropylphenyl stationary phase to make a stationary phase solution. The dynamic coating method is used to coat the cyanopropylphenyl stationary phase solution on the inner wall of the elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com