A kind of high tortuosity lithium-ion battery thin film and preparation method thereof

A lithium-ion battery, tortuosity technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as reducing the safety performance of lithium batteries, reducing the puncture strength of diaphragms, and increasing the risk of short circuit due to positive and negative contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

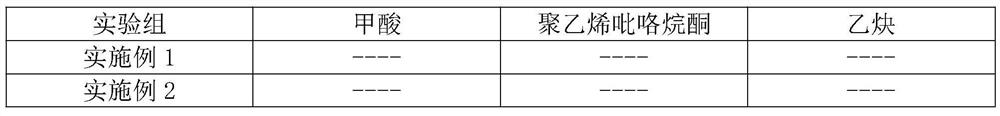

Embodiment 1

[0049] The dispersant also includes methylnaphthalene.

[0050] The polyvinylpyrrolidone is made from formaldehyde, acetylene, a catalyst and hydrogen.

[0051] The catalyst is copper acetylene, nickel, copper and potassium hydroxide.

[0057] (5) Heat setting: the film after the secondary transverse stretching is subjected to heat setting treatment, and the heat setting temperature is 100 °C.

Embodiment 2

[0061] The dispersant also includes methylnaphthalene.

[0062] The polyvinylpyrrolidone is made from formaldehyde, acetylene, a catalyst and hydrogen.

[0063] The catalyst is copper acetylene, nickel, copper and potassium hydroxide.

[0069] (5) Heat setting: the film after the secondary transverse stretching is subjected to heat setting treatment, and the heat setting temperature is 100 °C.

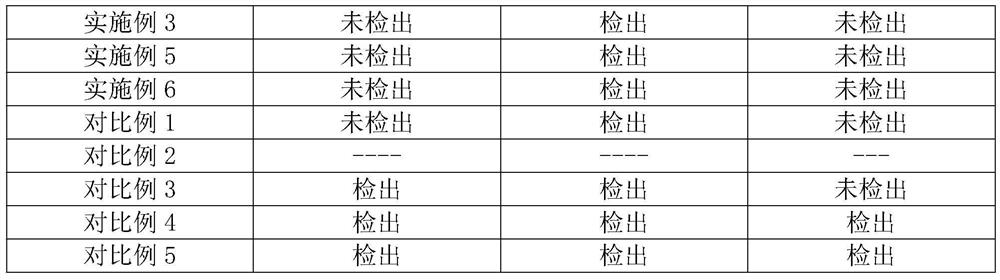

Embodiment 3

[0073] The dispersant also includes methylnaphthalene.

[0074] The polyvinylpyrrolidone is made from formaldehyde, acetylene, a catalyst and hydrogen.

[0075] The catalyst is copper acetylene, nickel, copper and potassium hydroxide.

[0090] (5) Heat setting: the film after the secondary transverse stretching is subjected to heat setting treatment, and the heat setting temperature is 100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com