A method for preparing monodisperse cross-linked polymer microspheres with high yield

A cross-linked polymer, monodisperse technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of long polymerization time, monomer conversion rate and low yield of microspheres, etc. Yield improvement, high cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] At room temperature, first add 90.0g of water / acetonitrile mixed solvent with a mass ratio of 25 / 75 to a 120mL glass reaction bottle, then add 2.48g of triethylenetetramine and 7.52g of isophorone diisocyanate respectively, and shake it evenly The reaction bottle was sealed and placed in a constant temperature water bath at 30°C. After 4 minutes of reaction, the system became cloudy, and then continued to react for 0.5 hours. After the reaction, the product was centrifuged with a high-speed centrifuge at 8,000 rpm for 5 minutes, the microspheres were washed twice with acetonitrile, and then dried in an oven at 100°C for 5 hours to obtain monodisperse cross-linked polyurea microspheres.

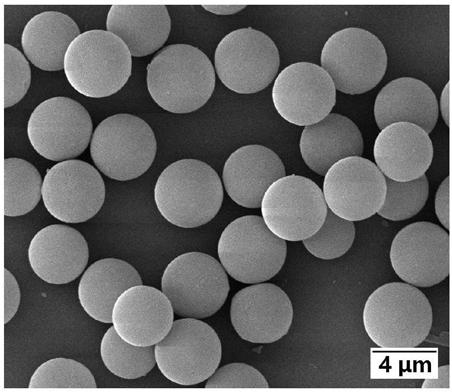

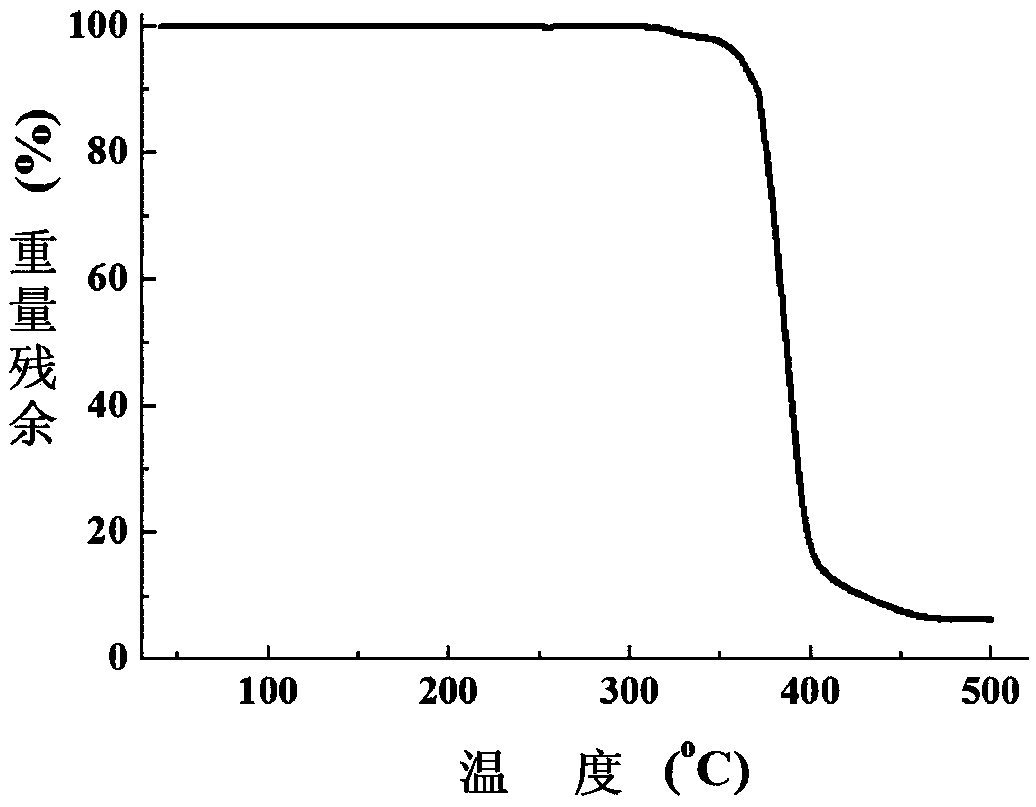

[0041] The obtained polyurea is 100% cross-linked, and the yield of polyurea microspheres is 88.23%. Scanning electron microscope pictures of microspheres as figure 1 As shown, the average particle size of the microspheres thus measured was 4.5 μm, and the polydispersity coefficient o...

Embodiment 2

[0043] Add 80.0g of acetonitrile to a 120mL glass reaction bottle at room temperature, then add 5.91g of triethylenetetramine and 14.09g of toluene diisocyanate respectively, shake evenly, seal the reaction bottle and place it in a constant temperature water bath at 30°C. After 10 minutes of reaction, the system became cloudy, and then continued to react for 1 hour. After the reaction, the product was centrifuged with a high-speed centrifuge at 8,000 rpm for 5 minutes, the microspheres were washed twice with acetonitrile, and then dried in an oven at 100°C for 5 hours to obtain monodisperse cross-linked polyurea microspheres.

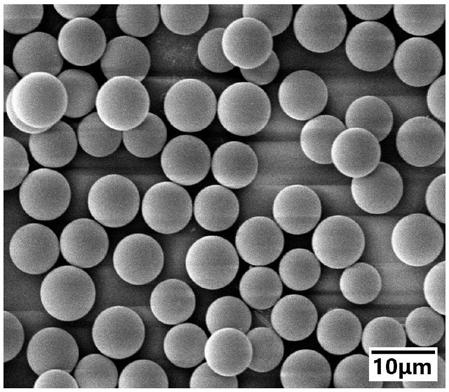

[0044] The obtained polyurea is 100% cross-linked, and the yield of polyurea microspheres is 93.51%. The average particle size of the microspheres is 8.5 μm, and the polydispersity coefficient of the particle size is 1.007.

Embodiment 3

[0046] At room temperature, first add 75.0g of water / acetonitrile mixed solvent with a mass ratio of 10 / 90 to a 120mL glass reaction bottle, and then add 5.75g of triethylenetetramine and 19.25g of isophorone diisocyanate respectively, and shake it evenly The reaction bottle was sealed and placed in a constant temperature water bath at 70°C. After 3 minutes of reaction, the system became cloudy, and then continued to react for 0.5 hours. After the reaction, the product was centrifuged with a high-speed centrifuge at 8,000 rpm for 5 minutes, the microspheres were washed twice with acetonitrile, and then dried in an oven at 100°C for 5 hours to obtain monodisperse cross-linked polyurea microspheres.

[0047] The cross-linked product in the obtained polyurea accounts for 97.4%, and the yield of polyurea microspheres is 94.84%. The average particle size of the microspheres is 9.5 μm, and the polydispersity coefficient of the particle size is 1.008.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com