High-tortuosity lithium ion battery film and preparation method thereof

A lithium-ion battery, tortuosity technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as reducing the safety performance of lithium batteries, difficulty in self-fusing and closing of diaphragms, and increasing the risk of short circuit due to positive and negative contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

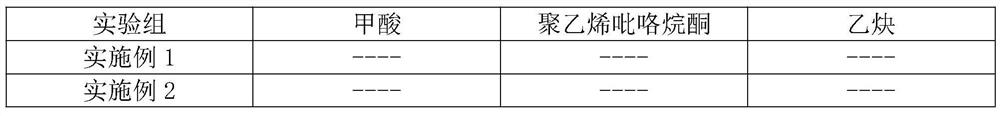

Embodiment 1

[0047] A high tortuosity lithium-ion battery film, made of the following raw materials by weight percentage, porogen 67%, ultra-high molecular weight polyethylene 29.4%, polycarbonate 0.2%, random copolymer polypropylene 2%, chlorinated 0.2% polyethylene, 0.2% polymethyl methacrylate, 0.2% dispersant, 0.2% reinforcing fiber, 0.2% colloidal silicon dioxide, 0.2% compatibilizer, 0.2% crosslinking agent.

[0048] The dispersant is polyvinylpyrrolidone, the porogen is white oil, the compatibilizer is a maleic anhydride graft compatibilizer, the cross-linking agent is a vinyl silane cross-linking agent, and the molecular weight of ultra-high molecular weight polyethylene is 2,000,000 .

[0049] The dispersant also includes methylnaphthalene.

[0050] The polyvinylpyrrolidone is made from formaldehyde, acetylene, catalyst and hydrogen.

[0051] The catalyst is acetylene copper, nickel, copper and potassium hydroxide.

[0052] A kind of preparation method of high tortuosity lithiu...

Embodiment 2

[0059] A high tortuosity lithium-ion battery film, made of the following raw materials by weight percentage, porogen 70%, ultra-high molecular weight polyethylene 26.5%, polycarbonate 0.2%, random copolymer polypropylene 2%, chlorinated 0.2% polyethylene, 0.2% polymethyl methacrylate, 0.2% dispersant, 0.2% reinforcing fiber, 0.2% colloidal silicon dioxide, 0.2% compatibilizer, 0.2% crosslinking agent.

[0060] The dispersant is polyvinylpyrrolidone, the porogen is white oil, the compatibilizer is a maleic anhydride graft compatibilizer, the cross-linking agent is a vinyl silane cross-linking agent, and the molecular weight of ultra-high molecular weight polyethylene is 2,000,000 .

[0061] The dispersant also includes methylnaphthalene.

[0062] The polyvinylpyrrolidone is made from formaldehyde, acetylene, catalyst and hydrogen.

[0063] The catalyst is acetylene copper, nickel, copper and potassium hydroxide.

[0064] A kind of preparation method of high tortuosity lithiu...

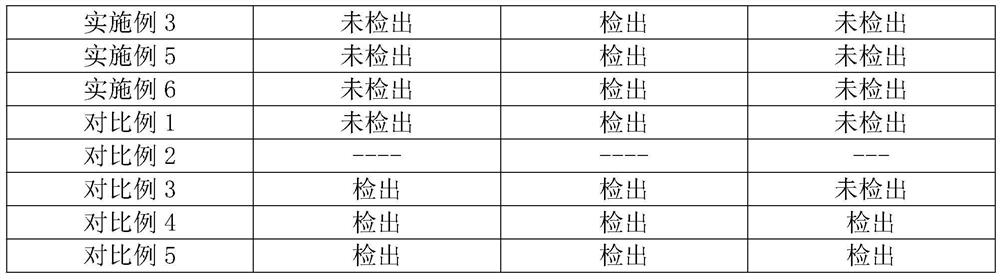

Embodiment 3

[0071] A high tortuosity lithium-ion battery film, made of the following raw materials by weight percentage, porogen 74%, ultra-high molecular weight polyethylene 25%, polycarbonate 0.1%, random copolymer polypropylene 0.1%, chlorinated 0.1% polyethylene, 0.1% polymethyl methacrylate, 0.1% dispersant, 0.1% reinforcing fiber, 0.2% colloidal silicon dioxide, 0.1% compatibilizer, 0.1% crosslinking agent.

[0072] The dispersant is polyvinylpyrrolidone, the porogen is white oil, the compatibilizer is a maleic anhydride graft compatibilizer, the cross-linking agent is a vinyl silane cross-linking agent, and the molecular weight of ultra-high molecular weight polyethylene is 2,000,000 .

[0073] The dispersant also includes methylnaphthalene.

[0074] The polyvinylpyrrolidone is made from formaldehyde, acetylene, catalyst and hydrogen.

[0075] The catalyst is acetylene copper, nickel, copper and potassium hydroxide.

[0076] A kind of preparation method of high tortuosity lithiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com