Adhesive, protection film comprising same, and coating tool

An adhesive and coating technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of strong adhesive force, easy peeling off of the protective film, and difficult peeling, so as to improve the adhesive force, Extend storage period and ensure flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a kind of preparation method of adhesive, it comprises the steps:

[0054] Mixing the raw material components in the first component to obtain a mixed solution;

[0055]Add the second component to the mixed liquid in stages and mix; the first stage is, under the protective gas, add a part of the second component to the mixed liquid, and react at 50-60°C for 1-1.5h , the second stage is: add the remaining second component to the mixed solution, react at 75-80° C. for 2-3 hours, and cool down to obtain the adhesive.

[0056] Among them, the addition of the second component in stages is conducive to the full polymerization of the monomeric substances in the adhesive to form polyhydroxyacrylic acid resin, which is beneficial to obtain an adhesive that has good adhesion at high temperature and is not easy to leave residual glue after laminating the product.

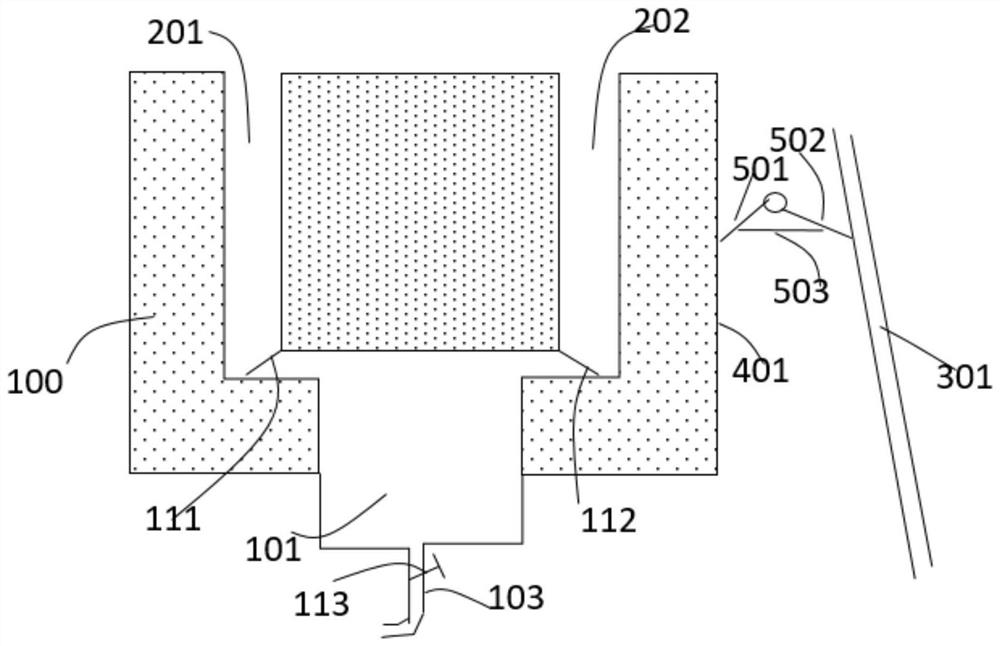

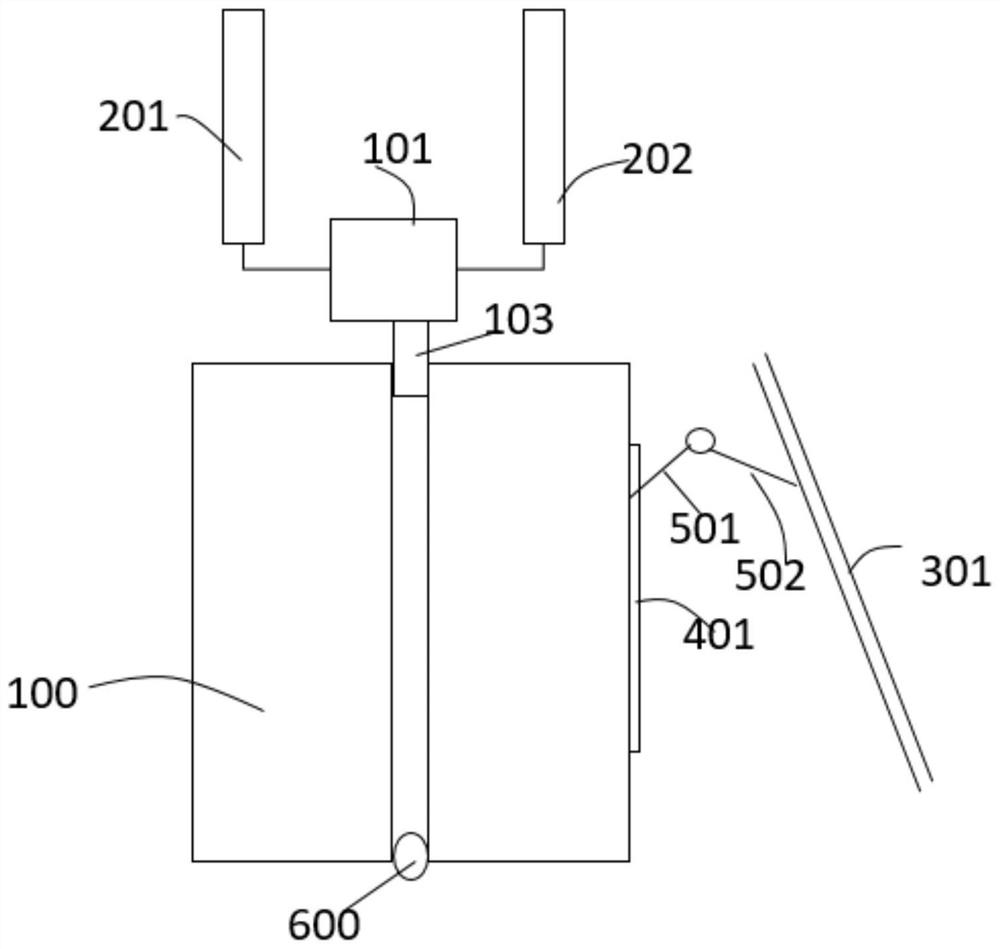

[0057] The present invention also provides a coating tool suitable for making th...

Embodiment 1

[0072] refer to figure 1 , a kind of method that adopts tool of the present invention to make protective film, comprises the steps:

[0073] An adhesive layer with a film thickness of 10 μm was formed on a PET substrate to obtain a protective film.

[0074] Wherein, the preparation process of adhesive layer is as follows:

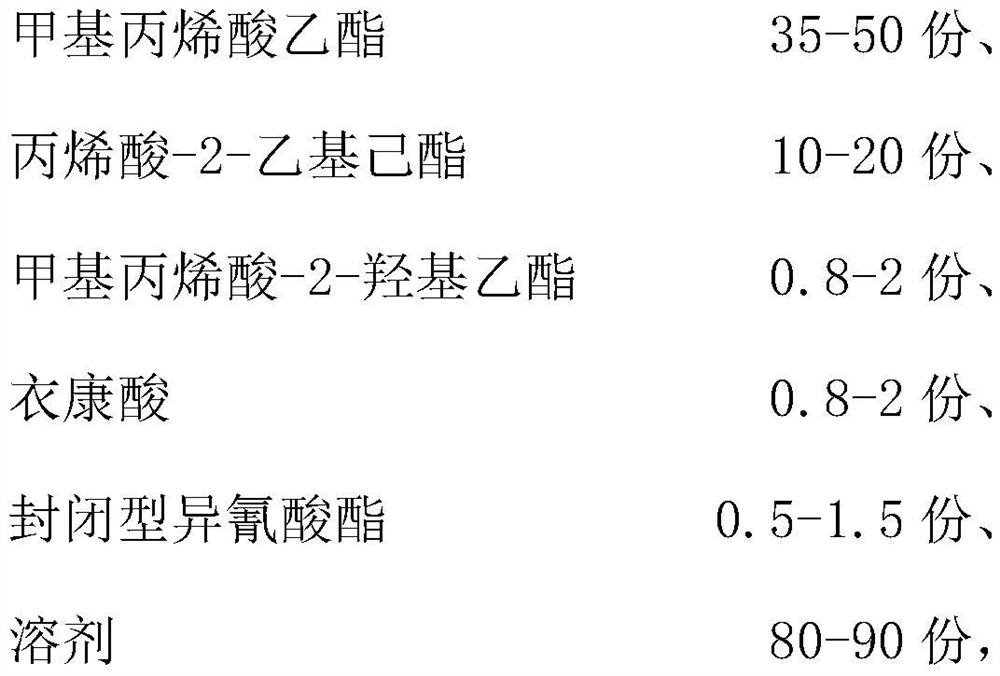

[0075] Put 35 parts of ethyl methacrylate, 12 parts of 2-ethylhexyl acrylate, 0.8 parts of 2-hydroxyethyl methacrylate, 0.8 parts of itaconic acid, 0.5 parts of blocked isocyanate and 85 parts of ethyl acetate After being mixed in the first component containing chamber 201 , the first valve 111 is opened to release the mixed liquid into the liquid mixing chamber 101 .

[0076] Open the second valve 112, feed protective gas nitrogen, and release 0.2 parts of azobisisobutyronitrile in the second component holding chamber 202 into the mixed liquid in the mixed liquid chamber 101 according to the reading on the scale. Heat up the cavity wall of body 101, rea...

Embodiment 2

[0079] refer to figure 1 , a kind of method that adopts tool of the present invention to make protective film, comprises the steps:

[0080] An adhesive layer with a film thickness of 10 μm was formed on a PET substrate to obtain a protective film.

[0081] Wherein, the preparation process of adhesive layer is as follows:

[0082] Put 43 parts of ethyl methacrylate, 15 parts of 2-ethylhexyl acrylate, 1.3 parts of 2-hydroxyethyl methacrylate, 1.2 parts of itaconic acid, 1 part of blocked isocyanate and 85 parts of ethyl acetate After being mixed in the first component containing chamber 201 , the first valve 111 is opened to release the mixed liquid into the liquid mixing chamber 101 .

[0083] Open the second valve 112, and under the action of protective gas nitrogen, release 0.4 parts of azobisisobutyronitrile in the second component holding chamber 202 into the mixed liquid in the mixed liquid chamber 101 according to the reading of the scale, and the heat mixing The cavi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com