Corona-resistant high-PDIV enameled copper flat wire for 800V driving motor and method

A drive motor, 1.800V technology, applied in the direction of circuits, electrical components, insulated cables, etc., can solve the problems of low corona resistance life, poor economic practicability, short service life, etc., achieve good adhesion and prevent excessive curing speed Fast, the effect of repairing layer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

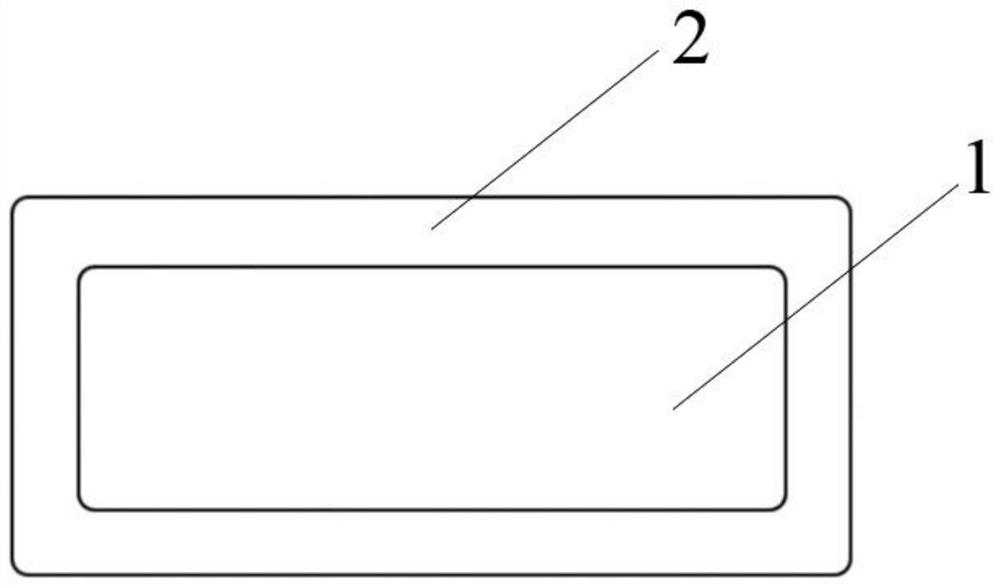

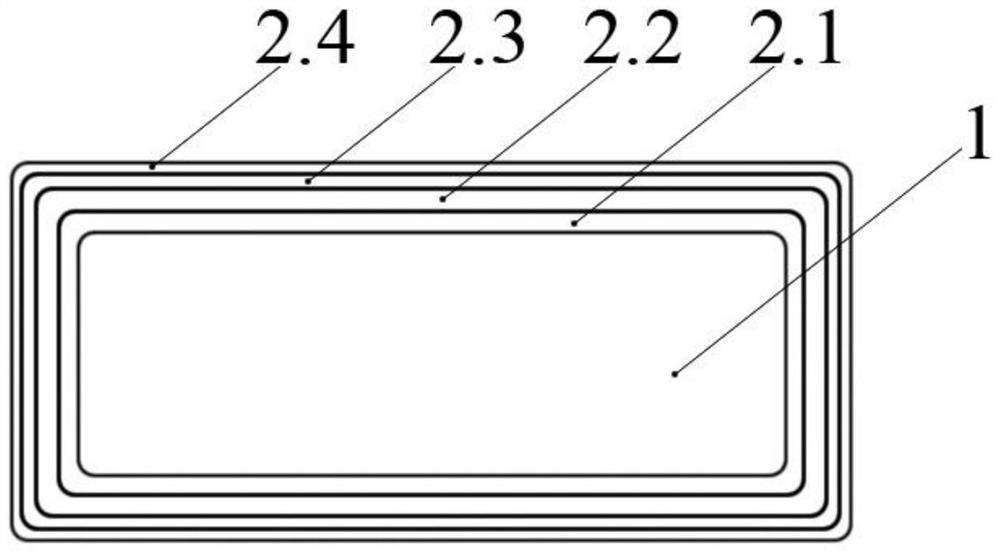

[0046] Corona resistant high PDIV enamelled copper flat wire for 800V drive motor, such as figure 1 and 2 As shown, the enamelled copper flat wire includes copper flat wire 1 and paint film 2, and paint film 2 includes primer layer 2.1, middle paint layer I2.2, middle paint layer II2.3, top paint layer 2.4; The thickness is 0.29mm;

[0047] The thickness of the primer layer 2.1 is 0.02mm; the thickness of the middle paint layer I2.2 is 0.15mm, the thickness of the middle paint layer II2.3 is 0.05mm; the thickness of the top coat layer 2.4 is 0.07mm;

[0048] Primer layer 2.1 is polyimide paint, model HI-409-2803;

[0049] The middle paint layer I2.2 is a corona-resistant paint, and the mass parts of the raw material components of the corona-resistant paint are: 35 parts of xylene, 20 parts of polyethylene wax, tris (2-hydroxyethyl) isocyanurate 15 parts, 10 parts of nano glass powder, 25 parts of phenol, 15 parts of 4,4'-diphenylmethane diisocyanate, 15 parts of N-methyl-2-...

Embodiment 2

[0071] Corona resistant high PDIV enamelled copper flat wire for 800V drive motor, such as figure 1 and 2 As shown, the enamelled copper flat wire includes copper flat wire 1 and paint film 2, and paint film 2 includes primer layer 2.1, middle paint layer I2.2, middle paint layer II2.3, top paint layer 2.4; The thickness is 0.28mm;

[0072] The thickness of the primer layer 2.1 is 0.02mm; the thickness of the middle paint layer I2.2 is 0.15mm, the thickness of the middle paint layer II2.3 is 0.05mm; the thickness of the top coat layer 2.4 is 0.06mm;

[0073] Primer layer 2.1 is polyimide paint, model HI-409-2803;

[0074] The middle paint layer Ⅰ2.2 is a corona-resistant paint, and the mass parts of the raw material components of the corona-resistant paint are: 40 parts of xylene, 30 parts of polyethylene wax, tris (2-hydroxyethyl) isocyanurate 18 parts, 20 parts of nano glass powder, 30 parts of phenol, 16 parts of 4,4'-diphenylmethane diisocyanate, 18 parts of N-methyl-2-...

Embodiment 3

[0096] Corona resistant high PDIV enamelled copper flat wire for 800V drive motor, such as figure 1 and 2 As shown, the enamelled copper flat wire includes copper flat wire 1 and paint film 2, and paint film 2 includes primer layer 2.1, middle paint layer I2.2, middle paint layer II2.3, top paint layer 2.4; The thickness is 0.30mm;

[0097] The thickness of the primer layer 2.1 is 0.03mm; the thickness of the middle paint layer I2.2 is 0.16mm, the thickness of the middle paint layer II2.3 is 0.05mm; the thickness of the top coat layer 2.4 is 0.06mm;

[0098] Primer layer 2.1 is polyimide paint, model HI-409-2803;

[0099] The middle paint layer I2.2 is a corona-resistant paint, and the mass parts of the raw material components of the corona-resistant paint are: 38 parts of xylene, 25 parts of polyethylene wax, tris (2-hydroxyethyl) isocyanurate 17 parts, 15 parts of nano glass powder, 28 parts of phenol, 16 parts of 4,4'-diphenylmethane diisocyanate, 17 parts of N-methyl-2-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com