TMR stirrer material contact surface treatment process

A treatment process and contact surface technology, applied in the direction of mixer accessories, mixers, anti-corrosion coatings, etc., can solve the problems of easy-to-corrosion TMR mixers, poor wear resistance of coatings, and easy to pollute feed, etc., to reduce friction coefficient and enhance durability Wear corrosion resistance, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

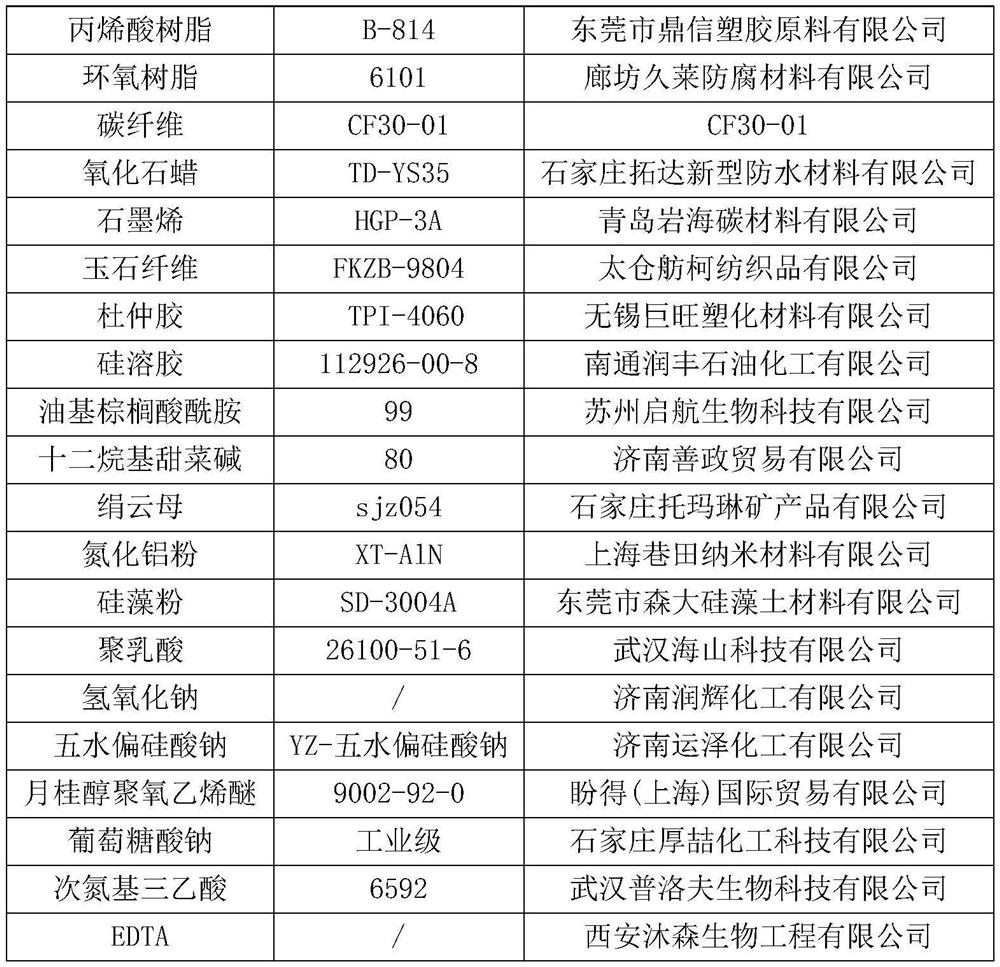

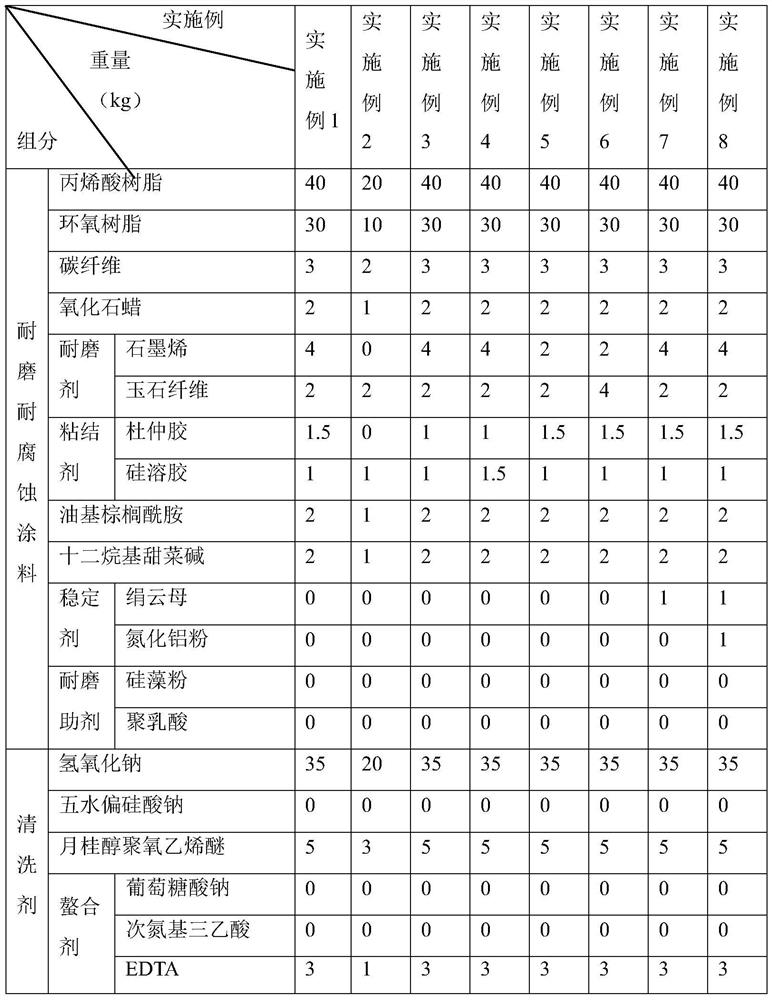

[0059] A kind of TMR mixer material contact surface treatment process, the concrete component that comprises and weight are as shown in table 2, are made by following steps:

[0060] S1: Preparation of cleaning agent: Mix and stir sodium hydroxide, polyoxyethylene lauryl ether, chelating agent and deionized water at a stirring speed of 1000r / min, and obtain a cleaning agent after stirring evenly;

[0061] Preparation of wear-resistant and corrosion-resistant coatings: Mix and stir acrylic resin and epoxy resin at a stirring speed of 1200r / min. After stirring evenly, the first mixture is obtained; mix the first mixture with oxidized paraffin wax, oleyl palmitic acid amide, dodecane The base betaine is mixed and stirred, and the stirring speed is 1000r / min, and the second mixture is obtained after stirring evenly; the second mixture is mixed and stirred with the wear-resistant agent and the binder, and the stirring speed is 1000r / min, and the stirring is uniform and then left sta...

Embodiment 2

[0065] Embodiment 2: a kind of TMR mixer material contact surface treatment process, the difference with embodiment 1 is that the components and weight of cleaning agent and wear-resistant and corrosion-resistant coating are different, and the included concrete components and weight are as shown in table 2 .

Embodiment 3-4

[0066] Embodiment 3-4: a kind of TMR mixer material contact surface treatment process, the difference with embodiment 1 is that the components and weight of the binder are different, and the specific components and weight included are as shown in table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com