Multi-stage freezing automatic water purifier and multi-stage freezing water purification method using same

A water purifier and automatic technology, applied in the direction of chilled water/sewage treatment, chemical instruments and methods, multi-stage water treatment, etc., can solve the problems of non-recoverable, heavy metals cannot be removed by ultrafiltration membrane treatment, high cost of use, etc., to achieve Reduce energy loss, improve ice melting effect, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

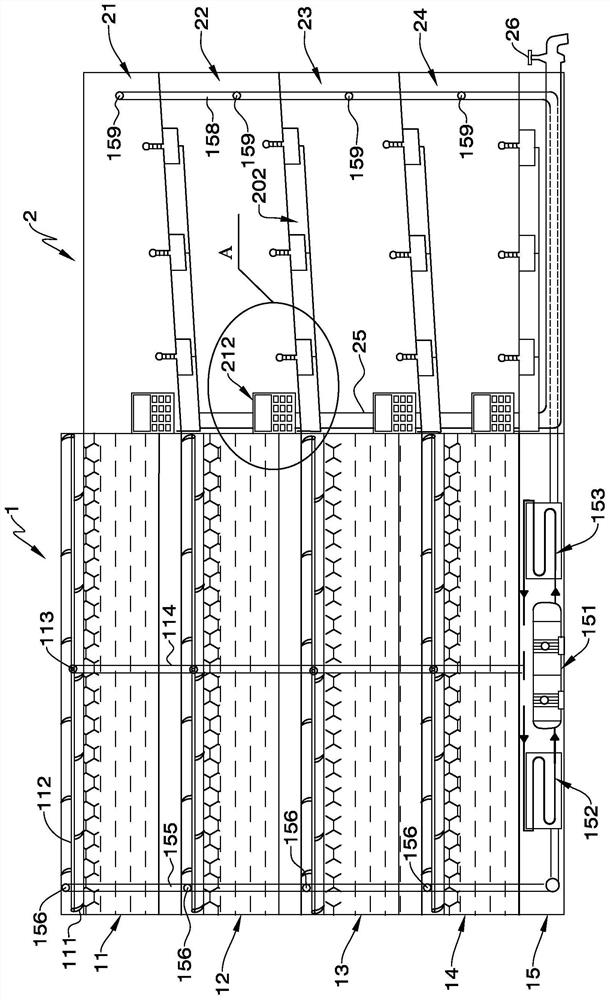

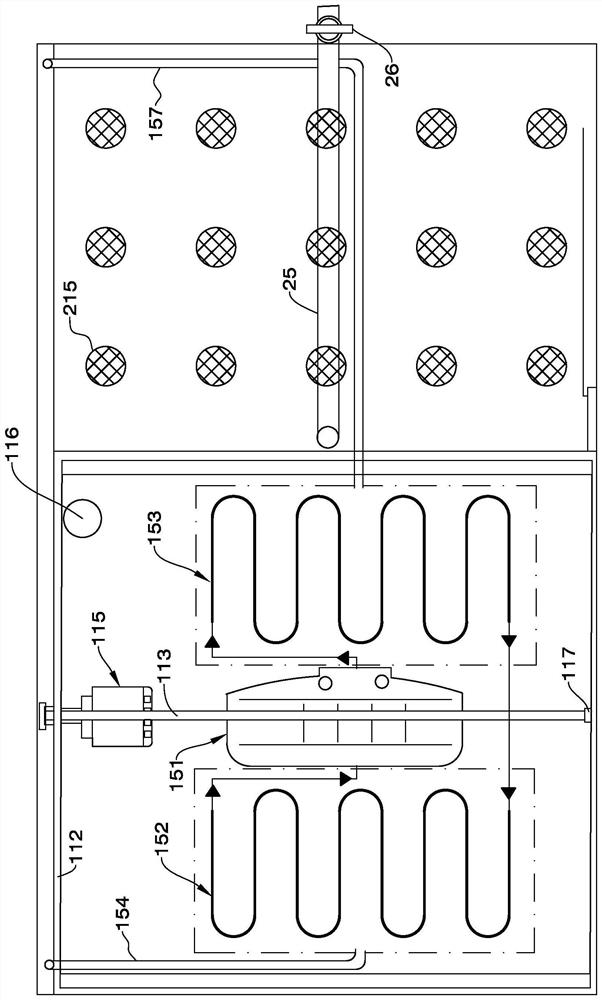

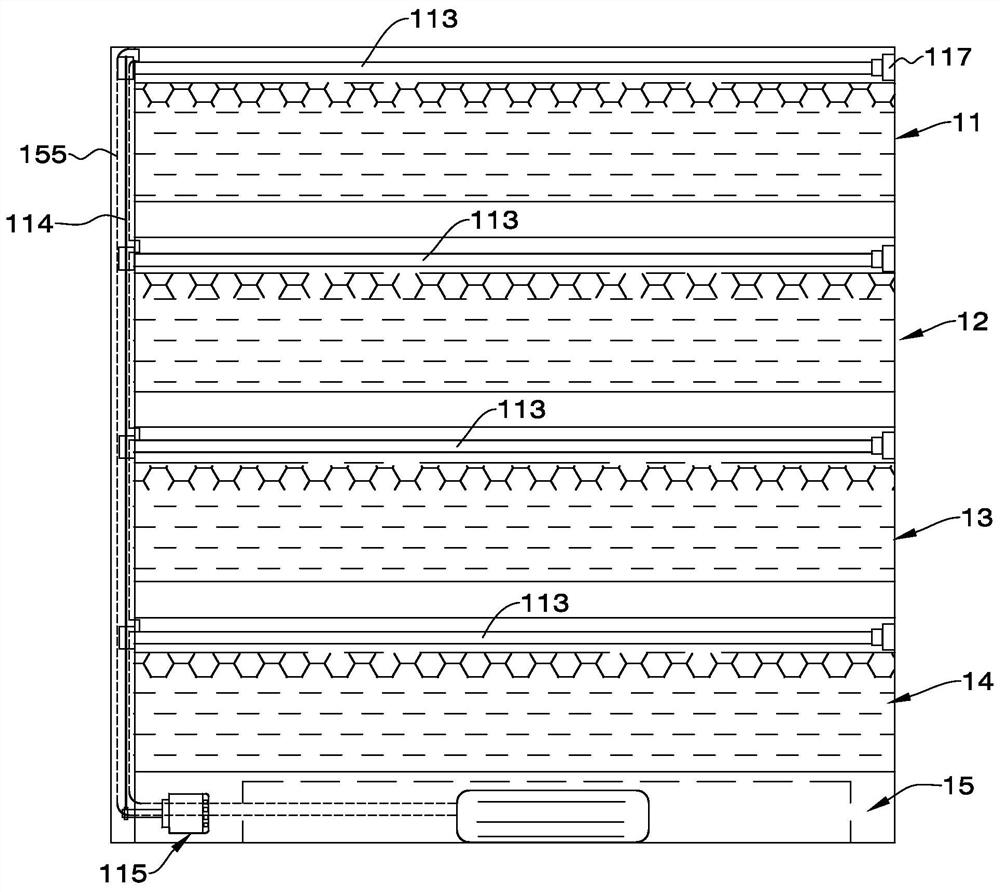

[0033] Such as Figure 1 to Figure 4 As shown, the multi-stage freezing automatic water purifier of the present invention includes a freezing module 1 and a melting module 2. The freezing module 1 includes several freezing pools arranged sequentially from top to bottom, and the melting module 2 includes one-to-one correspondence with the freezing pools. several melting pools. In this embodiment, the freezing module 1 includes primary freezing pools 11, secondary freezing pools 12, tertiary freezing pools 13, and fourth-stage freezing pools 14 that are stacked sequentially from top to bottom. The melting module 2 includes primary melting pools 21, secondary freezing pools The primary melting pool 22, the third-level melting pool 23, and the fourth-level melting pool 24, the primary melting pool 21 corresponds to and communicates with the primary freezing pool 11, the secondary melting pool 22 corresponds to and communicates with the secondary freezing pool 12, and the third-lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com