Low-oil-output heat-conducting gel and preparation method thereof

A technology of oil heat conduction and gel, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of extrusion rate reduction, affecting production efficiency, affecting the performance of heating elements and radiators, etc., to reduce oil output rate, reducing the effect of exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

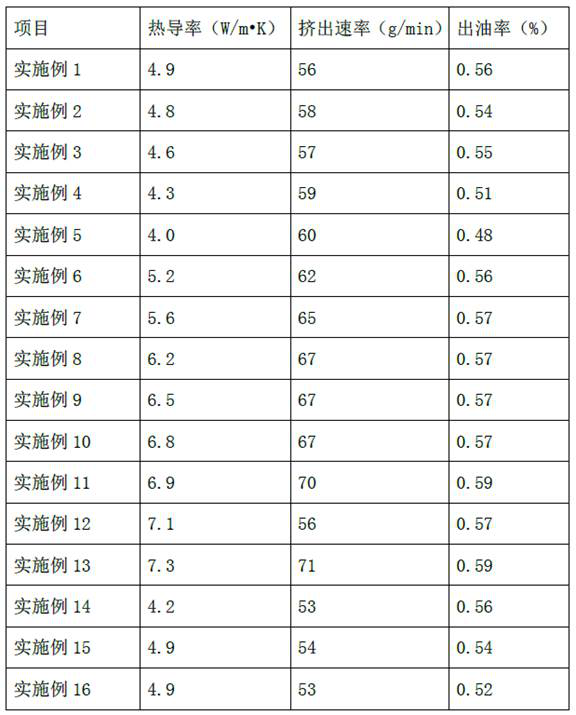

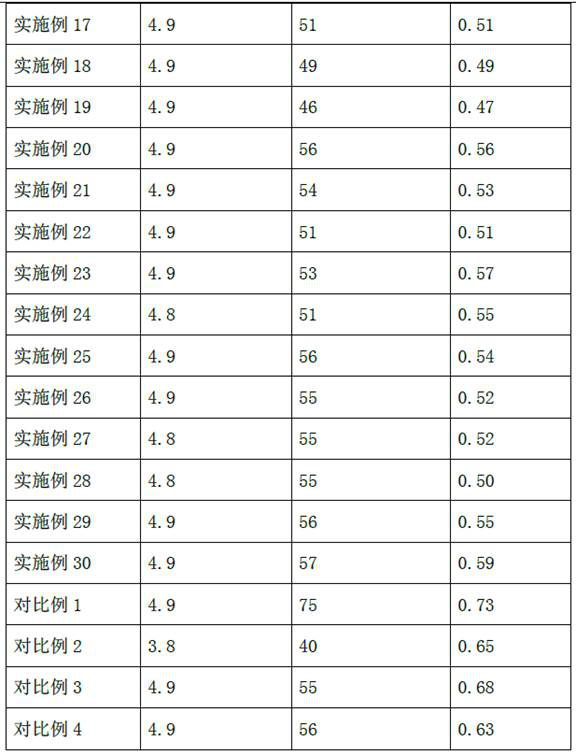

Examples

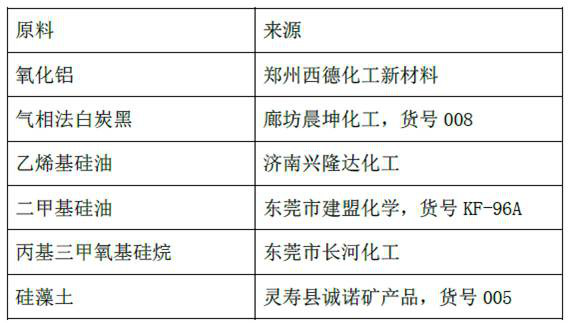

Embodiment 1

[0035] A thermally conductive gel with low oil output, made of the following raw materials: 919.5g of thermally conductive powder, 0.5g of fumed silica, 60g of silicone oil, and 20g of coupling agent. Among them, the heat-conducting powder can be selected from one of alumina, zinc oxide, boron nitride, aluminum nitride, silicon dioxide, and aluminum hydroxide. In this embodiment, alumina with a particle size of 0.5 μm is selected; silicone oil is optional From one of vinyl silicone oil, phenyl silicone oil, hydroxyl silicone oil, dimethyl silicone oil, polyether modified silicone oil, and long-chain alkyl silicone oil, this embodiment uses vinyl silicone oil with a viscosity of 140cps; the coupling agent is optional Self-propyltrimethoxysilane, decyltrimethoxysiloxane, phenylsiloxane, γ-aminopropyltriethoxysilane, γ-(2,3-epoxypropoxy)propyltrimethoxy One of the base silanes, the present embodiment selects propyl trimethoxy silane; the white carbon black is fumed white carbon b...

Embodiment 2

[0038] A low-oil thermally conductive gel, made of the following raw materials: 930g thermally conductive powder, 5g fumed silica, 50g silicone oil, and 15g coupling agent. The thermal conductive powder is alumina with a particle size of 0.5, the silicone oil is vinyl silicone oil with a viscosity of 140cps, the coupling agent is propyltrimethoxysilane, and the silica is fumed silica with a specific surface area of 140.

Embodiment 3

[0040] A low-oil thermally conductive gel, made of the following raw materials: 872.6g thermally conductive powder, 1.7g fumed silica, 118.3g silicone oil, and 7.4g coupling agent. The thermal conductive powder is alumina with a particle size of 0.5, the silicone oil is vinyl silicone oil with a viscosity of 140cps, the coupling agent is propyltrimethoxysilane, and the silica is fumed silica with a specific surface area of 140.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com