Large-area copper nanofoam with hierarchical structure for use as electrode

A nano- and nano-porous copper technology, applied in structural parts, battery electrodes, electrode carriers/current collectors, etc., can solve problems such as nano-porous copper manufacturing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

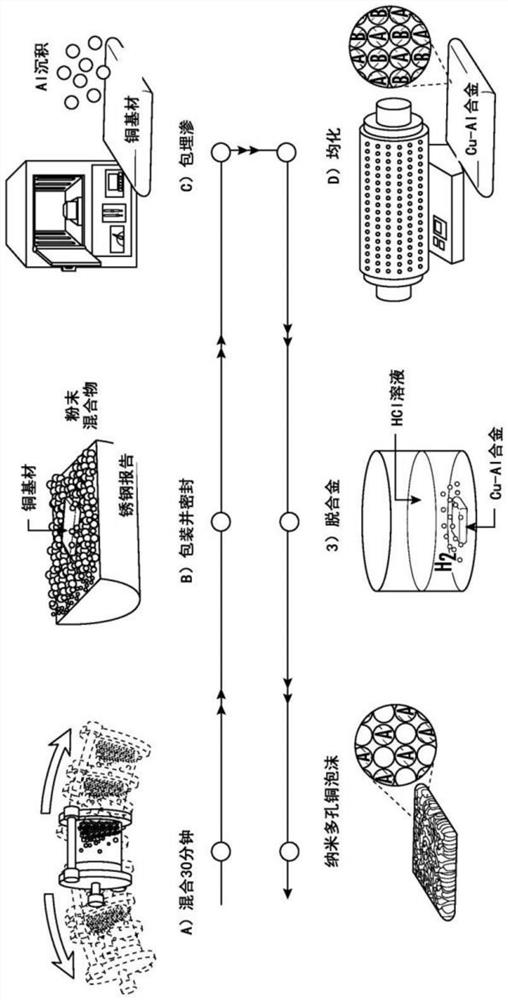

[0032] Embodiment 1: Nanoporous copper sample preparation

[0033] Aluminum-copper alloy precursors were synthesized using the inclusion infiltration method prior to dealloying. figure 1 A simplified diagram of the overall processing route is shown. The first step shows the mixing of the powders used in the embedding infiltration process. The powder consists of 3% by weight NH as activator 4 Cl powder (100 microns, Alfa Aesar, USA), 15 wt% pure aluminum powder (99.8%, +325 mesh, Alfa Aesar, USA) as coating metal source and 82 wt% Al as filler 2 o 3 Powder (60 μm, Alfa Aesar, USA) composition. Mechanical mixing (8000-DMixer Mill, SPEX Sample Prep, USA) was performed for 30 minutes to obtain a homogeneously mixed powder. After mixing, package and seal using stainless steel wrappers ( figure 1 b) for subsequent heat treatment steps; then embedding infiltration at a constant 800°C ( figure 1 c) Duration of 15 minutes, 30 minutes, 3 hours, 6 hours, 12 hours or 15 hours to...

Embodiment 2

[0034] Embodiment 2: chemical tin coating process

[0035] To demonstrate the performance of the as-synthesized nanoporous copper as an anode for lithium-ion batteries, a high-capacity anode active material (tin) was coated onto nanoporous copper by electroless plating. Immerse the nanoporous copper in the tin plating solution at 60 °C for 1 min. The tin plating solution consists of 2 grams of anhydrous tin(II) chloride (SnCl 2 2H 2 O), 2 grams of sodium phosphate monohydrate (sodiumphosphate monohydrate) (NaH 2 PO 2 2H 2 O), 10.5 grams of thiourea (CS(NH 2 ) 2 ) and 0.84 ml of concentrated hydrochloric acid in 200 ml of deionized water. Subsequently, the tin-coated nanoporous copper anode sample was heat-treated at 150 °C for 1 h in a tube furnace in an argon atmosphere.

Embodiment 3

[0036] Embodiment 3: Lithium-ion battery button cell cycle test

[0037] Copper disks were prepared with a diameter dimension of 11 mm and a thickness of 250 microns. A CR2032 type coin cell was assembled in a glove box in a dry argon atmosphere using a tin-coated nanoporous copper negative coupon as the working electrode and lithium metal foil for both the counter and reference electrodes. The electrolyte is a conventional 1.3 molar LiPF with ethylene carbonate (EC) and diethylene carbonate (DEC) in a volume ratio of 3:7 6 solution. Assembled coin cells containing tin-coated nanoporous copper negative electrode coupons were tested at a current density of 1 milliamp per square centimeter at a voltage range of 3.0 volts to 0.01 volts (for Li-ion / Li) at 25 degrees Celsius. Constant current test.

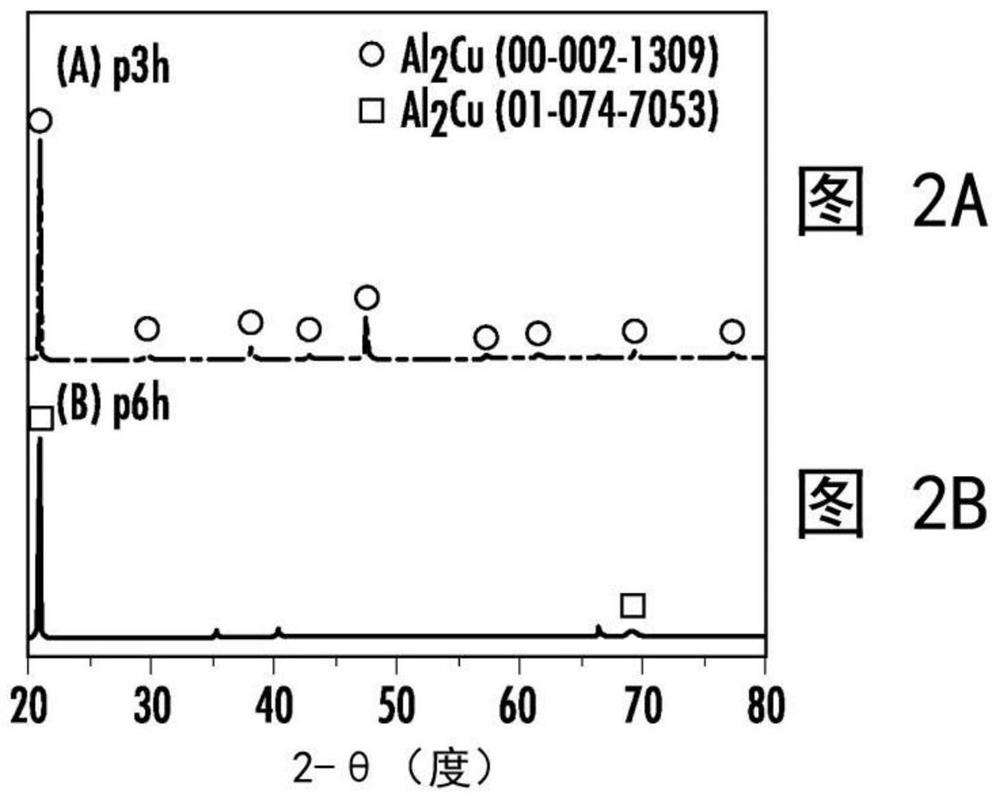

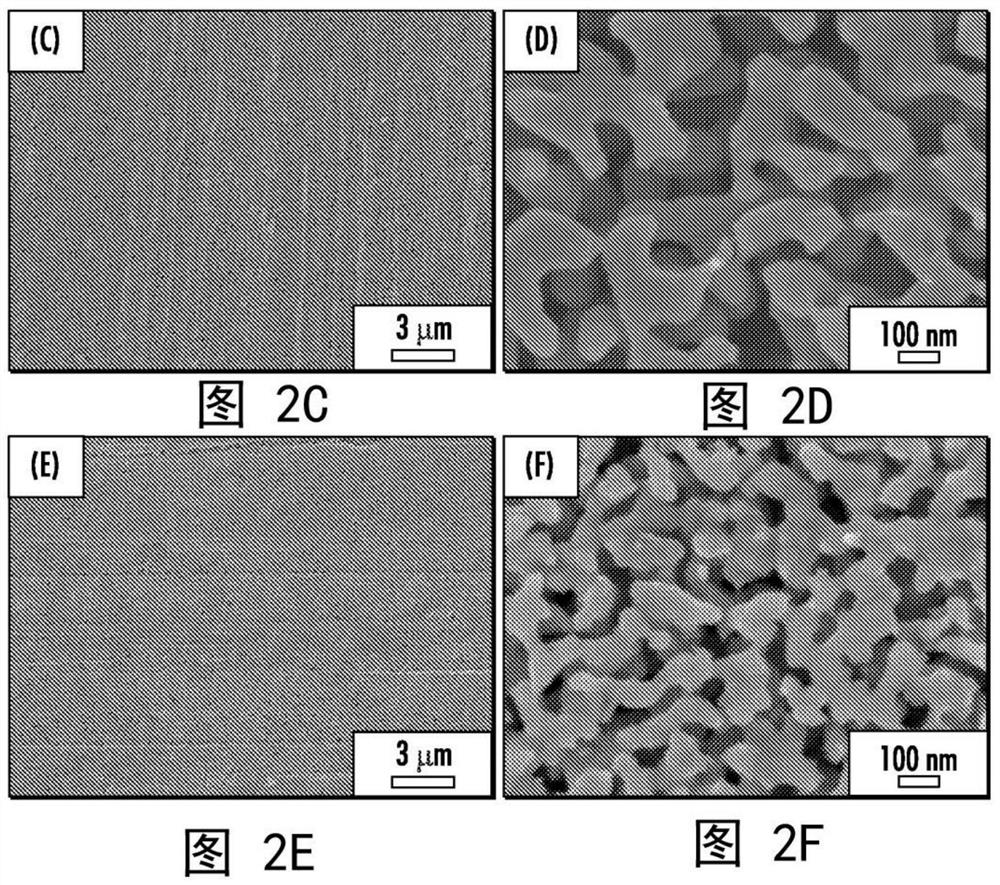

[0038] Example Results: Treatment of Al-Cu Precursors Based on Infiltration

[0039] The infiltration time was varied from 15 minutes to 15 hours to produce different aluminum-copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com