Oyster compound feed rich in fish oil and preparation method thereof

A technology for compounding feed and fish oil, applied in the field of feed, can solve problems such as unfavorable popularization and application, waste, poor suspension, etc., and achieve the effects of simple and reasonable composition, natural and environmentally friendly components, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

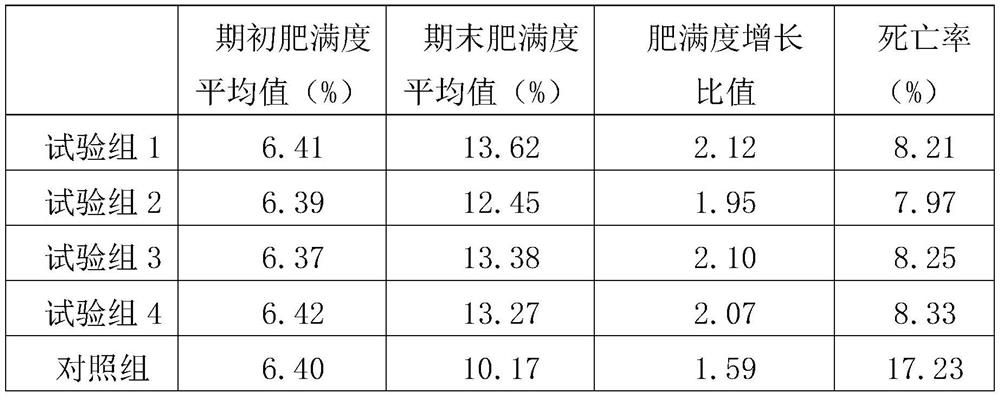

Examples

Embodiment 1

[0052] (1) Weigh respectively 4 parts of fish oil, 5 parts of Chrysopsis globosa, 15 parts of Schizochytrium sp., 15 parts of Spirulina platensis, 20 parts of Salina salina, 10 parts of Clostridium ethanol protein, and multivitamin additives in parts by weight. 0.5 parts, 0.5 parts of lipase, 0.5 parts of sucrose fatty acid ester, 5 parts of sodium caseinate, 24.5 parts of corn starch;

[0053] (2) Add fish oil into the oil pot, heat up to 70°C, add the sucrose fatty acid ester weighed in step (1), and stir at constant temperature for 30 minutes to obtain an oil phase liquid;

[0054] (3) Add water that is 7 times heavier than the total weight of the raw materials in step (1) into the emulsification tank, heat up to 70° C., add the cornstarch weighed in step (1), and stir at constant temperature for 30 minutes to obtain cornstarch liquid;

[0055] (4) Isochrysis globosa, Schizochytrium sp., Spirulina platensis, Salina, Clostridium ethanol, multivitamin additive, lipase and sod...

Embodiment 2

[0065] (1) Weigh 2 parts of fish oil, 10 parts of Isoflagellates, 10 parts of Schizochytrium, 10 parts of Spirulina platensis, 25 parts of Salina, 12 parts of Clostridium ethanol protein, and multivitamin additives in parts by weight 1 part, 1 part of lipase, 1 part of sucrose fatty acid ester, 8 parts of sodium caseinate, 20 parts of corn starch;

[0066] Reaction steps (2)~(12) are the same as embodiment 1.

Embodiment 3

[0068] (1) Weigh 5 parts of fish oil, 5 parts of Chrysopsis globosa, 20 parts of Schizochytrium sp., 20 parts of Spirulina platensis, 15 parts of Salina salina, 8 parts of Clostridium ethanol protein, and multivitamin additives in parts by weight. 0.5 parts, 0.5 parts of lipase, 1 part of sucrose fatty acid ester, 5 parts of sodium caseinate, 20 parts of corn starch;

[0069] Reaction steps (2)~(12) are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com